Spiral conveyors and a case lift have some key functions in common, but there are a lot of features that separate these two vertical transportation machines.

Let’s explore the difference between a spiral conveyor and a case lift. First, though, let’s define what a spiral conveyor and case lift are and describe their uses.

A spiral conveyor is known by a range of names, including belt incline conveyor, spiral elevator, vertical conveyor, vertical lift, spiral curve, helix and even Spiralveyor, a particular brand name.

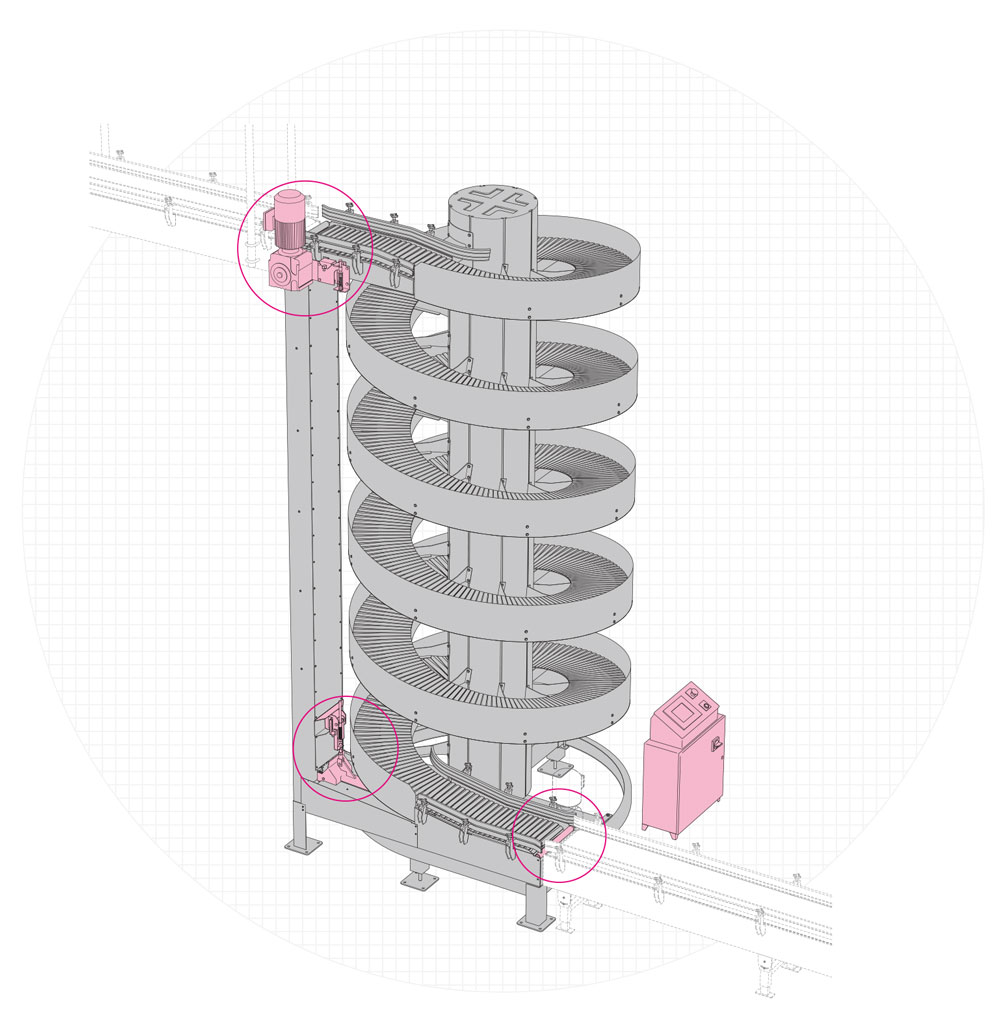

A spiral conveyor is a broad term used to describe two kinds of material-handling conveyor equipment, each which falls under a separate material handling category and caters to different industrial markets. One kind of spiral conveyor is a bulk material-handling screw conveyor, and the other kind is a belt or slat conveyor.

Bulk material-handling screw conveyors utilize an enclosed spiral screw to move loose bulk particles and powders vertically. Belt or slat conveyors use belts or slats to vertically move boxes, parcels, packages, trays, totes and other items—wrapped or unwrapped.

Both of these kinds of spiral conveyors transport products vertically rather than horizontally. Each of these spiral conveyor types are suited to serve some industries better than others, with spiral screw conveyors being valued especially by the agriculture, chemical processing, consumer product and food-processing industries and belt or slat conveyors used mostly in packaging and assembly, parcel handling and general manufacturing.

A case lift, also called a case elevator, is a machine that can lift cases, cartons and other packages vertically. With a case lift, a case enters the machine via a conveyor, and dual flights rise vertically to lift the case off the infeed conveyor and move it to the discharge elevation.

As with spiral conveyors, case lifts use minimal floor space. Although functional machines, case lifts represent outmoded design with very limited throughput capacity. They often suffer from rapid wear and tear that can bring operation to a halt and require time-consuming maintenance and repair periods.

Spiral conveyors and case lifts each transport products vertically rather than horizontally. Spiral conveyors, however, feature leading-edge, forward-thinking design. This improved design allows spiral conveyors to move loads substantially faster and more reliably than case lifts.

Spiral conveyors provide continuous material flow. Loads do not need to be synchronized to

lifting flights, improving throughput and removing bottlenecks.

An additional benefit of spiral conveyors is that they require significantly less maintenance compared with case lifts. This can result in tremendous money and time savings for businesses in terms of more uptime.

Investing in a spiral conveyor has elevated the work of one Ryson customer, Aptar Beauty, featured in our article “Spiral Conveyors replace Case Elevators.”

Jeff Danek, an Aptar engineer, reported that Aptar’s case lift had outlived its practical and cost-effective lifespan. “Being of chain-driven indexing design, it tended to wear components at an unacceptable rate,” he said.

Aptar’s operations also were severely affected by maintenance and repair time, both of which were “substantial” and frequently required the assistance of more than one team member. “Our operation often runs 24/7, so performing even minimal preventative maintenance is very difficult,” Danek said.

Initially, the Aptar Beauty team was intrigued by replacing their case lift with a Ryson Spiral Conveyor, but some technical supervisors expressed skepticism that the design was robust enough to support their operations. After viewing Ryson Spiral Conveyors at PACK EXPO and talking to a Ryson Spiral Conveyor customer, Aptar Beauty’s technical staff believed that a spiral conveyor could meet their expectations.

“The vertical spiral conveyor design also allowed us to make layout improvements,” Danek said. “It is very quiet in operation and is much easier to service. It integrated easily with our conveyor and palletizer system and installation went as planned. To date we are very pleased with the operation of the unit.”

As the leading U.S. manufacturer of spiral conveyors, Ryson Spiral Conveyors are designed using advanced technology that presents a long list of special features and benefits to our customers.

Ryson Spiral Conveyors require less of your business’ precious floor space thanks to their compact footprint in comparison with conventional spiral conveyors. They’re also faster and have proved to be more reliable than any elevator or lift, including case lifts.

Ryson Spiral Conveyors also are built with a horizontal area at the infeed and outfeed, helping ensure reliable and safe movement between the spiral and adjoining conveyors without products sustaining damage.

Our Spiral Conveyors’ automatic chain tensioning device and built-in overload protection come as standard features. Our one-drive motor offers substantial savings for businesses in energy, controls and systems integration compared with competitors’ products.

Additionally, Ryson’s Spiral Conveyors are easy to install and field modify, operate at a low noise level, offer high throughput and boast low maintenance needs and long lifespans.

Let’s explore some additional key features that make Ryson Spiral Conveyors stand out to our valued customers.

An innovative modular design allows Ryson to customize any spiral conveyor with ease and be economically modified in the field to accommodate changing needs. All configurations can operate up or down in a clockwise or counterclockwise rotation and can optionally be reversible. The position and length of the in feed tangent on up spirals and out feed tangent on down spirals can be customized to meet specific layout requirements.

Ryson’s proprietary slat belts enable a rolling low-friction operation without any sliding movements or wear strips on the spiral conveyor. The belt is pulled by a heavy-duty steel roller chain, and the slats are supported by precision steel roller bearings, which roll along a polyurethane surface.

This setup takes up the side forces created by a tight radius and simultaneously increases the belt’s load carrying capacity to 75 pounds per linear foot.

Ryson’s proprietary slat belt enables our Spiral Conveyors to start and stop fully loaded and facilitates high speed, low noise and long life.

Our Unit Load and High Capacity Spiral Conveyors utilize Ryson’s overlapping slats. They provide an efficient and safe conveying surface for cartons, cases, totes, trays and many other kinds of packaged products. Our overlapping slats come in the following widths: 8, 12, 16, 20, 24, 26, 30 and 36 inches. Moreover, friction inserts may be added when extra grip is required.

Our Unit Load and High Capacity Spiral Conveyors utilize Ryson’s overlapping slats. They provide an efficient and safe conveying surface for cartons, cases, totes, trays and many other kinds of packaged products. Our overlapping slats come in the following widths: 8, 12, 16, 20, 24, 26, 30 and 36 inches. Moreover, friction inserts may be added when extra grip is required.

Ryson’s Mass Flow and Narrow Trak Spiral Conveyors feature our nesting slats, which convey small loads such as cans, jars, loose bottles and other containers. This conveying surface is flat, making for a smooth and reliable product side transfer. This can be done single file or en masse. Nesting slats are available in these widths: 6, 9, 10, 16 and 20 inches.

Ryson has developed proprietary spiral technology, enabling us to create specialty Spiral Conveyors that meet many of our customer’s needs.

Ryson also produces custom Spiral Conveyors that are made to our customers’ specifications. These conveyors are available in a wide range of sizes and configurations. Because of Ryson’s proprietary modular design, we can tailor orders with ease and modify our products to accommodate emerging needs.

Ryson Spiral Conveyors come in many configurations and accommodate most requirements connected to the in and out feed tangents’ locations. The position of the in feed tangent on up spirals and out feed tangent on down spirals can also be customized to meet specific layout requirements.

Ryson Spiral Conveyors are used in an increasing number of small and large companies in many industries. Our Spiral Conveyors can handle any conveyable loads, from bags, bottles, bundles, cans and containers to pales, totes, trays and unwrapped and wrapped goods.

Ryson Spiral Conveyors are frequently used as elevators or lowerators in packaging lines, many of which run around the clock. They are ideal in cold-storage and freezer applications in which floor space is at an absolute premium.

Our Spiral Conveyors are also valued for use as continuous lifts between floors in multilevel order-picking systems or any other vertical conveying applications, especially with limited floor space and high reliability is a must. These use cases include mass flow of full or empty bottles, cans, jars and other similar containers.