Ryson makes customer service a top priority. So we are very proud to announce that our Service Manager Jeffery Montgomery, and the rest of the service team are PMMI Certified Trainers.

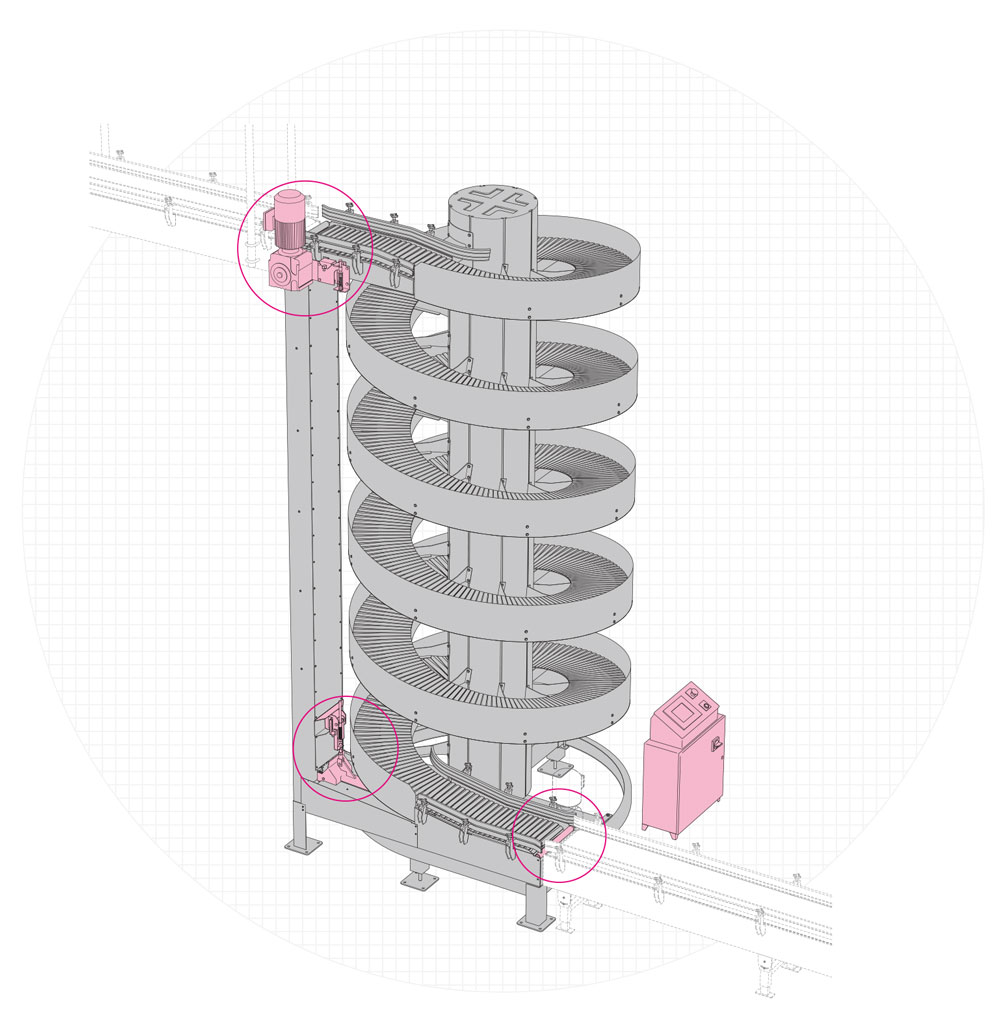

This allows us to properly train your staff about our Vertical Conveying Products. Proper integration and preventative maintenance greatly prolongs the life of our products and substantially reduces the cost of ownership. Download the Ryson Recommended Preventative Maintenance Program PDF.

The PMMI Certified Trainer Program teaches the skills needed to provide quality training to improve equipment reliability, employee safety and line efficiency. This proven train-the-trainer program is designed for both internal trainers at end user companies as well as service technicians and trainers at PMMI member companies. PMMI Certified Trainers are equipped with the tools and skills needed to increase productivity and efficiency in your operations through a highly interactive and performance-based training curriculum that emphasizes practical learning and problem-solving.

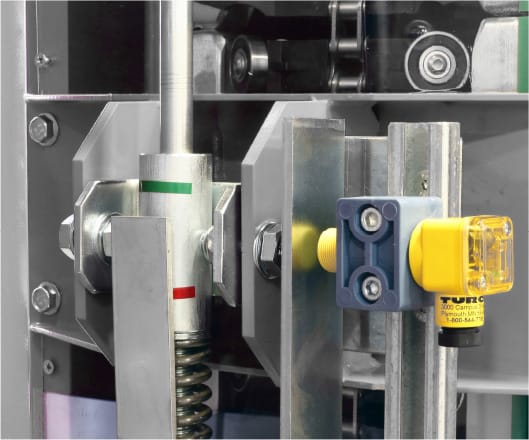

The bearings are lubricated for life and the chain requires infrequent lubrication. The chain will stretch during operation and needs to be shortened occasionally.

300 Newsome Drive

Yorktown, VA 23692

(757) 898-1530

sales@ryson.com