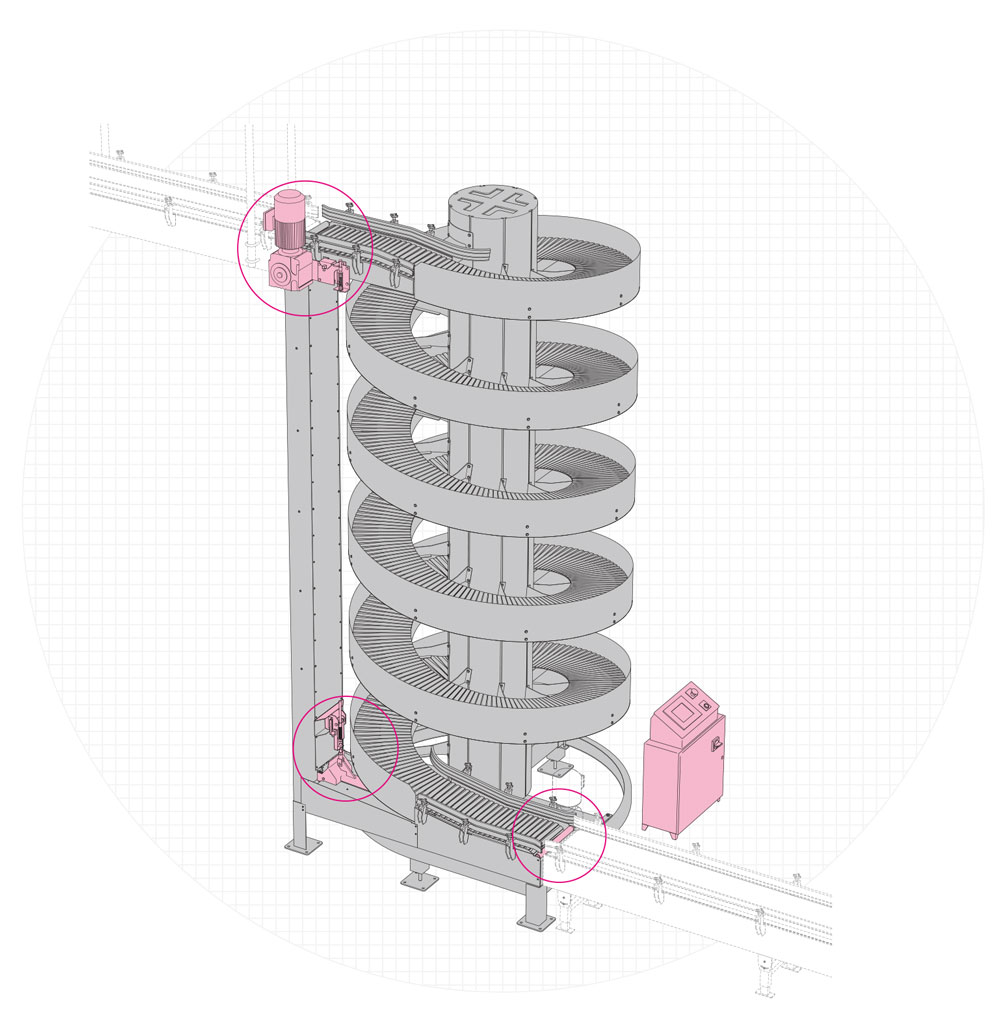

Most spirals are shipped in one piece, pre-assembled and pre-tested, drastically reducing time and cost of installation.

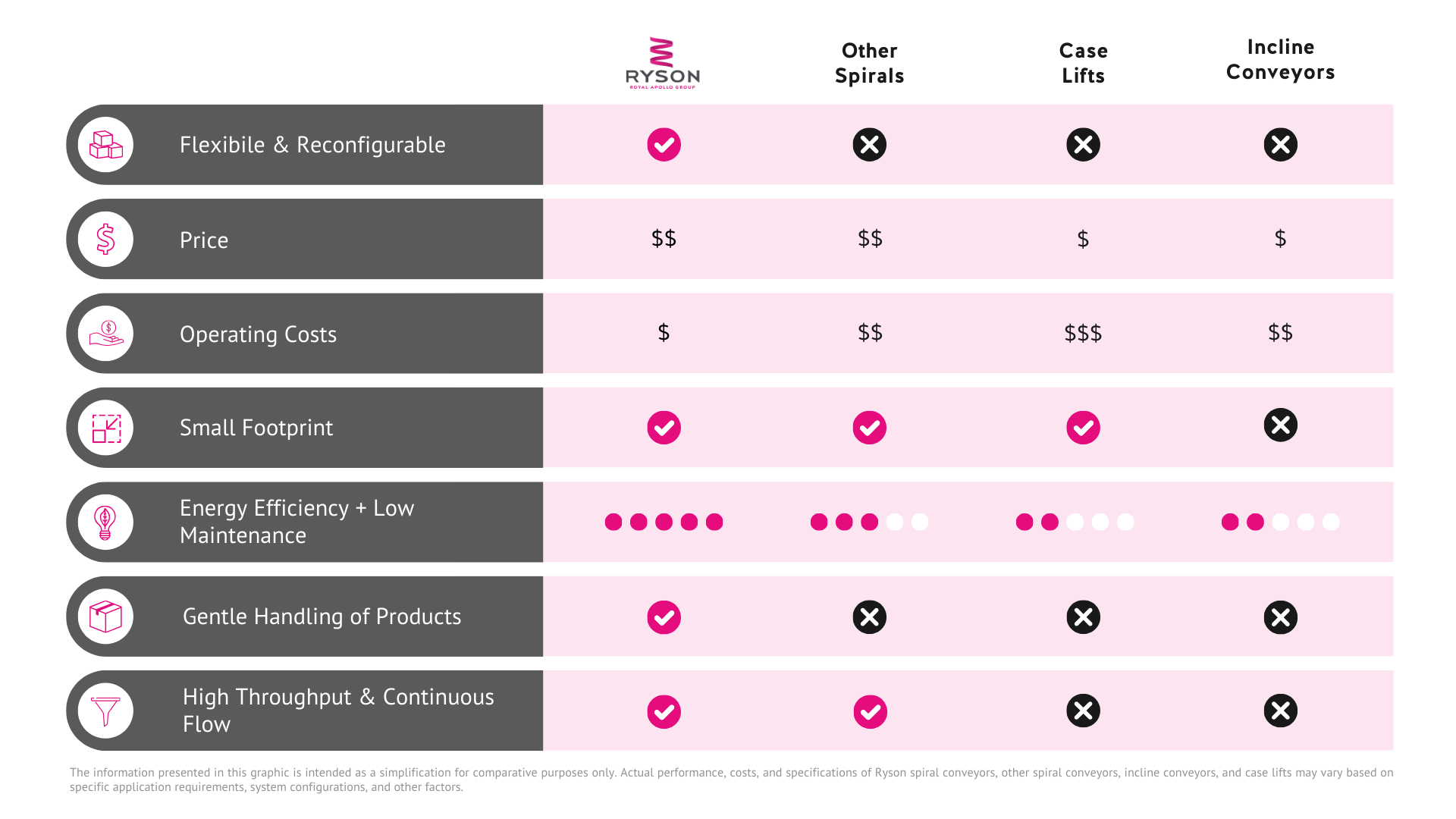

Our Spirals and components are designed for reliability. low maintenance and long life. They have an impressive up-time record reducing the total cost of ownership

All Ryson Spirals are equipped with an automatic chain tensioning device and built-in overload protection ensuring safe and reliable operation.

An innovative modular design allows Ryson to customize any spiral conveyor with ease and be economically modified in the field to accommodate changing needs.

All Ryson Spiral Conveyors are made to order and comes in a wide range of sizes and configurations.

Most Spirals are shipped without controls because they typically integrate with an overall conveyor control system. We do offer a number of controls and pre-wiring options. A Variable Frequency Drive (VFD) is required for proper operation of the spirals.

his innovative belt enables a low rolling friction operation without any sliding movements or wear strips on the spiral conveyor. The belt is pulled by a heavy duty steel roller chain and the slats are supported by precision steel roller bearings which ride on a polyurethane surface. This arrangement effectively takes up the side forces created by a tight radius and at the same time increases the load carrying capacity of the belt up to 75 lbs per linear foot. This enables the spiral conveyors to start and stop fully loaded and facilitates high speed, low noise and long life.

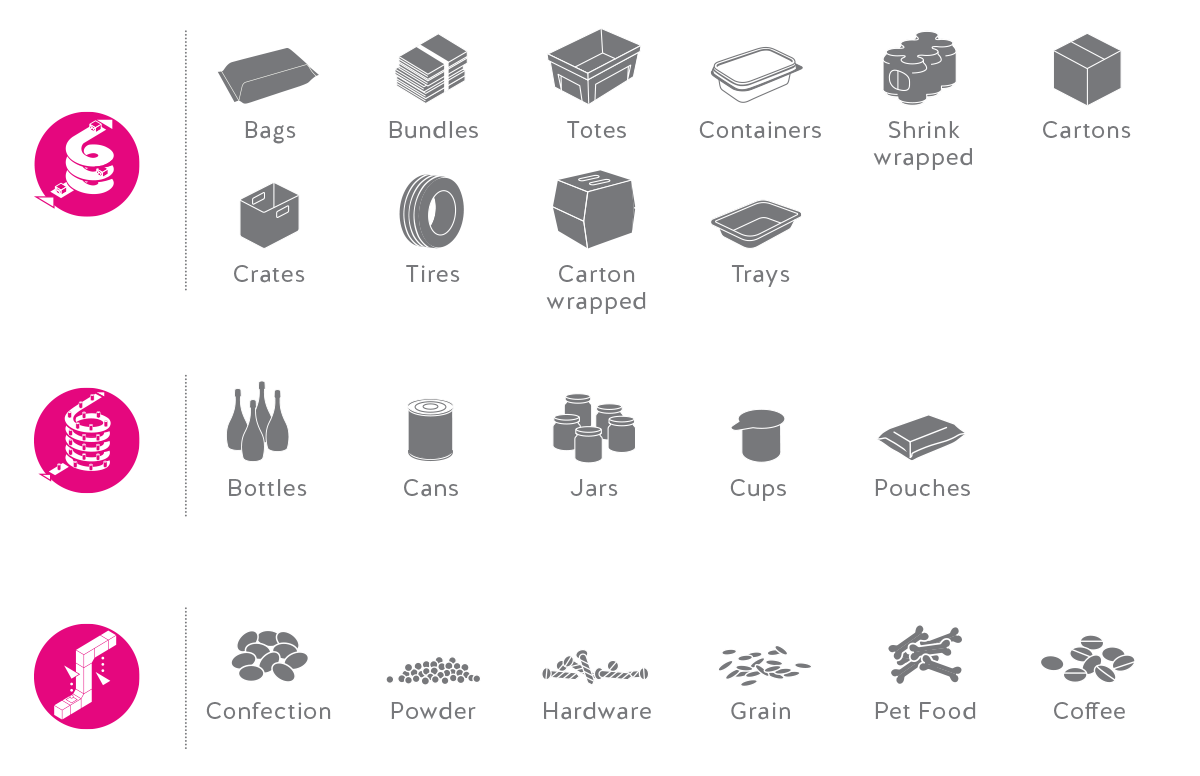

Overlapping slats are used on the Unit Load and High Capacity Spiral Conveyors, providing an efficient and safe conveying surface for cartons, cases, trays, totes and all sorts of packaged products. Available in 8”, 12”, 16”, 20”, 24” , 26, 30” and 36″ wide slats. Friction inserts can be optionally added when additional grip is required.

Nesting slats are used in the Mass Flow and Narrow Trak Spiral Conveyors that convey small loads including loose bottles, cans, jars and similar containers. The conveying surface is flat without gaps, facilitating a smooth and reliable product side transfer. This can be done in a single file or in mass. They are available in 6”, 9”, 10”, 16” and 20” wide slats.

Only one drive motor is required, resulting in substantial savings in energy, controls and systems integration.

The proprietary low friction chain slat belt allow Ryson Spiral Conveyors to operate within a small footprint, saving valuable floor space. See the individual product charts for specific dimensions on our most popular models.

All Ryson Spirals are designed with a horizontal section at the in and outfeed. This assures a safe and reliable transition between the spiral and adjoining conveyors without product damage and undue wear.

300 Newsome Drive

Yorktown, VA 23692

(757) 898-1530

sales@ryson.com