- Overview

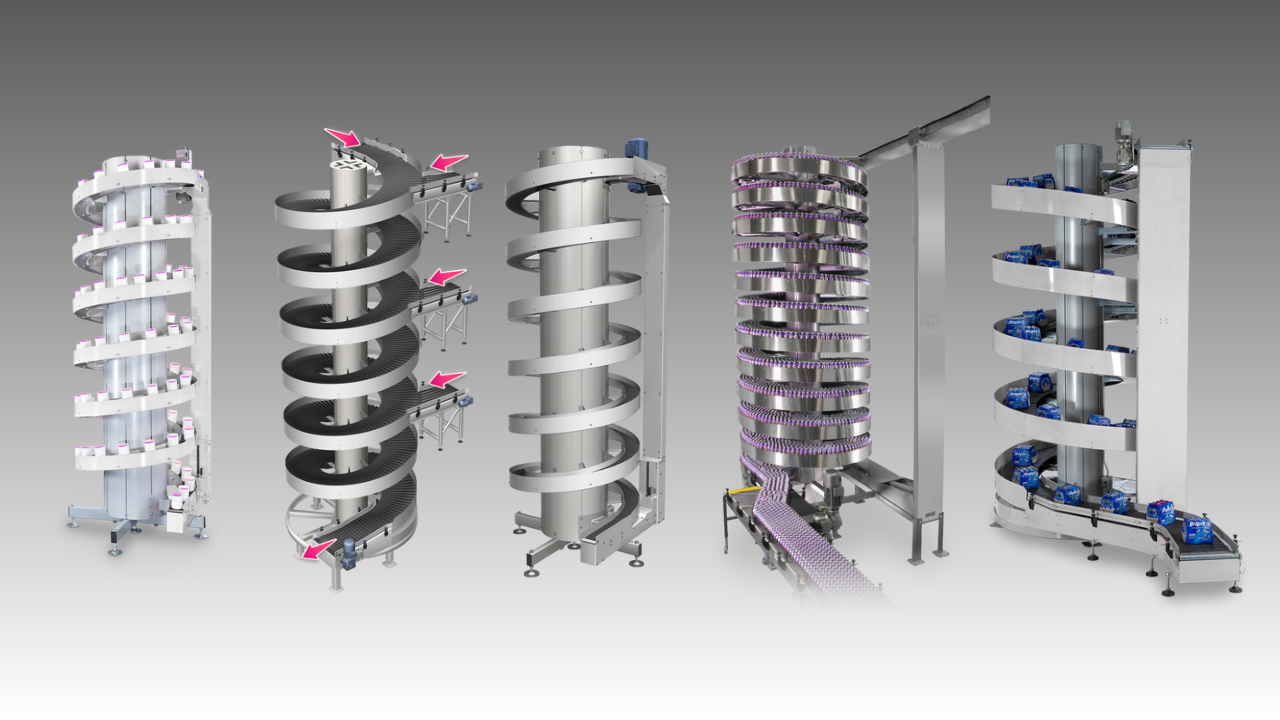

The Ryson Wide Track Spiral Conveyors are our largest and most robust Spiral models in our High Capacity line.

Ryson Spiral Conveyors need less floor space than conventional conveyors and are faster and more reliable than any elevator or lift. Our Wide Track models are ideal for conveying larger and heavier loads to greater heights. They are commonly used for heavier items, varied product sizes and where overhead space is used to maximize space utilization.

Our Wide Track Spirals are ideally suited for warehousing and order picking operations. They can handle double the capacity of our regular spirals.

Our efficient low friction chain system allows a load capacity is 75 lbs. per linear foot of conveyor for speeds up to 200 FPM. The total weight capacity in the spiral at any one time is 3600 lbs and the Spiral can start and stop fully loaded. It also requires only one drive motor, resulting in substantial savings in energy, controls and system integration.

Our efficient low friction chain system allows a load capacity is 75 lbs. per linear foot of conveyor for speeds up to 200 FPM. The total weight capacity in the spiral at any one time is 3600 lbs and the Spiral can start and stop fully loaded. It also requires only one drive motor, resulting in substantial savings in energy, controls and system integration.

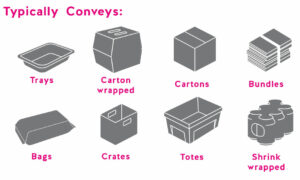

All our High Capacity Spirals can also optionally be configured to allow loads to enter and exit the spirals at several intermediate elevations. Special induction and divert conveyors have individually adjustable conveying surfaces to match the spiral pitch, assuring a safe and reliable product transfer. See our Multiple Entry and Exit Spirals page for more information. Ryson Spirals are designed for low maintenance and long life.

All our High Capacity Spirals can also optionally be configured to allow loads to enter and exit the spirals at several intermediate elevations. Special induction and divert conveyors have individually adjustable conveying surfaces to match the spiral pitch, assuring a safe and reliable product transfer. See our Multiple Entry and Exit Spirals page for more information. Ryson Spirals are designed for low maintenance and long life.

Our innovative modular design allows Ryson to customize with ease and modify in the field to accommodate emerging needs.

- Gallery

- Features & Benefits

Ryson Spiral Conveyors have many unique features that make them ideal Vertical Conveying Solutions. Many of our features are designed to save money in the long term, essentially lowering your total cost of ownership.

Design Flexibility: Our unique design offers flexibility of configuration. It also adds the ability to field modify to accommodate changing future needs at a fraction of the cost of a new conveyor.

Overlapping slats provide a smooth and efficient conveying surface, ensuring gentle product handling and suitable for all types of conveyable items. Our efficient rolling friction chain-slat design only needs a single drive, resulting in substantial savings in energy, controls and systems integration.

Overlapping slats provide a smooth and efficient conveying surface, ensuring gentle product handling and suitable for all types of conveyable items. Our efficient rolling friction chain-slat design only needs a single drive, resulting in substantial savings in energy, controls and systems integration.

Our innovative chain-slat design enables a low friction operation without any sliding movements or wear-strips. This allows the Spiral to stop and start fully loaded.

Our innovative chain-slat design enables a low friction operation without any sliding movements or wear-strips. This allows the Spiral to stop and start fully loaded.

Our efficient rolling friction chain-slat design only needs a single drive, resulting in substantial savings in energy, controls and systems integration.

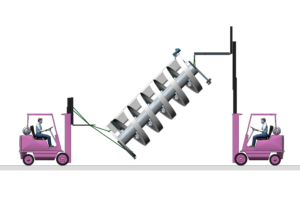

Simple to Install: Many models ship in one piece. All are pre-tested. Our larger units may require some disassembly for shipment. Installation is generally an efficient process and reduces time for implantation and integration.

Simple to Install: Many models ship in one piece. All are pre-tested. Our larger units may require some disassembly for shipment. Installation is generally an efficient process and reduces time for implantation and integration.

Our Spirals and components are designed for reliability, low maintenance and long life. They have an impressive up-time record reducing the total cost of ownership.

Click below to read details about more of our features:

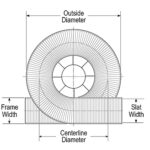

The proprietary low friction chain slat belt allow Ryson Spiral Conveyors to operate within a small footprint, saving valuable floor space. See the chart below for specific dimensions on our most popular models.

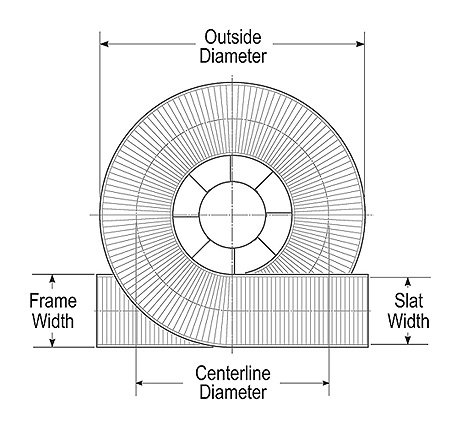

Our innovative modular design allows Ryson to customize any spiral conveyor with ease and can also be economically modified in the field to accommodate changing needs. All spiral conveyors are made to order and can operate up or down in a clockwise or counterclockwise rotation and can optionally be reversible. The position and length of the in feed tangent on up spirals and out feed tangent on down spirals can be customized to meet specific layout requirements.

All Ryson Spiral Conveyors are made to order and comes in a wide range of sizes and configurations.

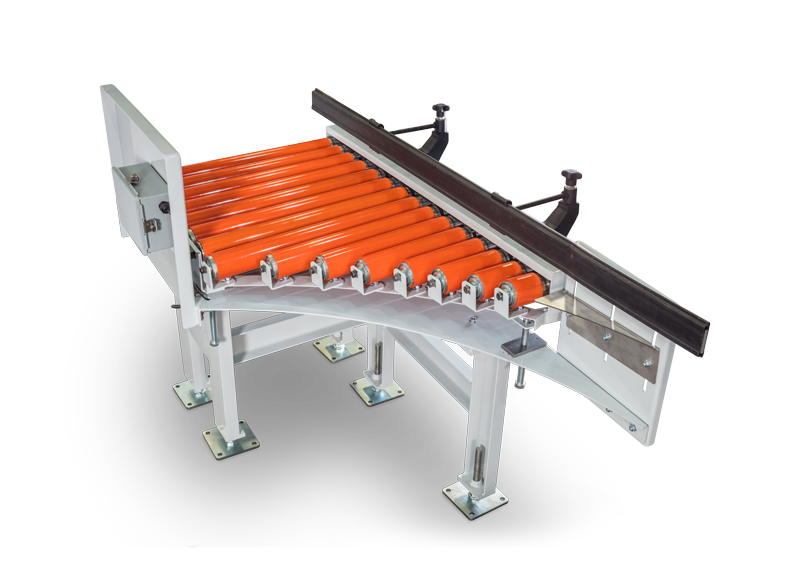

This innovative belt enables a low rolling friction operation without any sliding movements or wear strips on the spiral conveyor. The belt is pulled by a heavy duty steel roller chain and the slats are supported by precision steel roller bearings which ride on a polyurethane surface. This arrangement effectively takes up the side forces created by a tight radius and at the same time increases the load carrying capacity of the belt up to 75 lbs per linear foot. This enables the spiral conveyors to start and stop fully loaded and facilitates high speed, low noise and long life.

This innovative belt enables a low rolling friction operation without any sliding movements or wear strips on the spiral conveyor. The belt is pulled by a heavy duty steel roller chain and the slats are supported by precision steel roller bearings which ride on a polyurethane surface. This arrangement effectively takes up the side forces created by a tight radius and at the same time increases the load carrying capacity of the belt up to 75 lbs per linear foot. This enables the spiral conveyors to start and stop fully loaded and facilitates high speed, low noise and long life.

![]()

All Ryson Spiral Conveyors are equipped with an automatic chain tensioning device and built-in overload protection as a standard. This helps save both the Spiral and the product it is conveying.

Our proprietary chain slat belt assures a low noise operation, less than 75 db in most cases.

The Ryson modular design makes it easy to field modify our spirals in case of unplanned installation changes or to reconfigure and repurpose the spirals at a later date. Click to see some examples:

The Spiral Conveyors convey loads up or down in a continuous flow, facilitating high throughput. Many spirals can operate at speeds in excess of 200 FPM and are optionally reversible.

![]() Ryson Spirals are designed for low maintenance and long life. Only high quality components are used throughout. All bearings are sealed for life and need no further lubrication. The chain is of heavy duty nickel plated construction and needs only infrequent lubrication. The slats are made of a nylon composite, need no maintenance and can easily be replaced as single components without the use of special tools. Ryson has a full staff of factory trained service technicians ready to assist. All of our service techs are PMMI Certified Trainers. All of these factors contribute to Ryson’s low total cost of ownership.

Ryson Spirals are designed for low maintenance and long life. Only high quality components are used throughout. All bearings are sealed for life and need no further lubrication. The chain is of heavy duty nickel plated construction and needs only infrequent lubrication. The slats are made of a nylon composite, need no maintenance and can easily be replaced as single components without the use of special tools. Ryson has a full staff of factory trained service technicians ready to assist. All of our service techs are PMMI Certified Trainers. All of these factors contribute to Ryson’s low total cost of ownership.

- Specs & Configurations

Most Common Models

Diameter

Diameter

Width

Width

High Capacity / Wide Track Spirals

- Videos