This week, one of our service technicians is working on a field modification.

This week, one of our service technicians is working on a field modification.

Our reconfigure business is steadily growing. People are noticing that Ryson’s equipment has the ability to be modified… With relative ease, thanks to our modular design.

This makes total sense from a Cost of Ownership perspective. The cost of modifying a spiral is much less than the cost of a new spiral. Many of our customers have had unforeseen line changes that require changes to the dimensions or orientation of the Spiral. This can also be accomplished in under a day, in many cases.

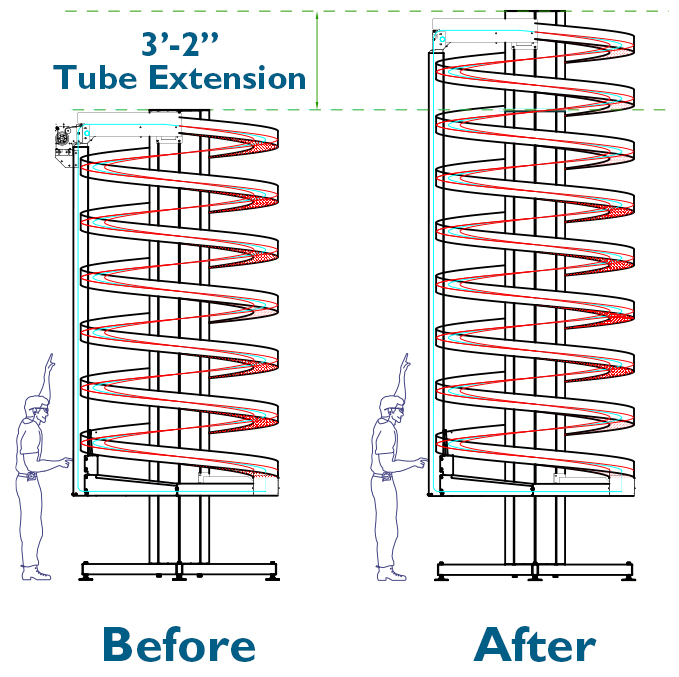

This week’s story is a perfect example. Our Customer needed s design change after the Spiral was delivered. In this case, the 1700-230 NT Spiral needed an additional 3′ -2″ elevation change. Then we fabricated the replacement parts and shipped to the end user. Start to finish, the conversion from a 6 ¼ turn spiral to a 8 ¼ turn machine took four weeks. Then, one of our service technicians traveled to site to assist millwrights in the modification.

The Integrator Partner for this project is Integrated Packaging Machinery. The line handles containers of vegetable oil going down through a hole penetration. The project manager was impressed with how responsive we were and our ability to handle the challenge quickly.

This is a perfect example of the value of Ryson reconfiguration.

This is part of our commitment to lower total cost of ownership. Again, the expense for this fieled modification is a fraction of the cost for a replacement spiral.

Lastly for additional information about the advantages of our modular design, check out our website, or read other field reconfiguration stories in our weekly news blog.