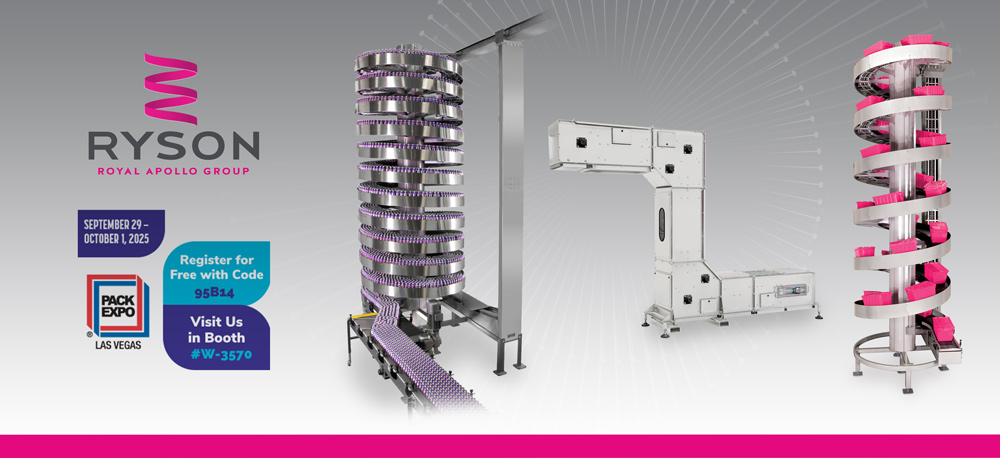

Ryson Offers FREE Registration to PackExpo 2025

Pack Expo 2025 is quickly approaching, and we would like to extend you free registration if you are planning to attend…

At the end of September, Pack Expo, the largest packaging show in the USA will be taking place in Las Vegas. Ryson is excited to show off a large booth with many of our machines running, covering a large spectrum of vertical conveying application solutions.

Register to Pack Expo 2025 for free

Register to Pack Expo 2025 for free

We are also very pleased to announce that we are extending Free Registration to our Integrators and Customers. Simply visit https://pelv2025.nvytes.co/invite25/95B14.html, and enter our comp code, and the registration fee will be waived prior to your checkout.

Ryson Will Showcase Innovative Conveying Solutions at Pack Expo 2025 in Las Vegas

Pack Expo 2025 in Las Vegas will once again bring together the leaders of packaging and material handling. Ryson is excited to exhibit three of our most versatile conveying solutions. Each highlights how we help manufacturers and distributors improve efficiency and save valuable floor space.

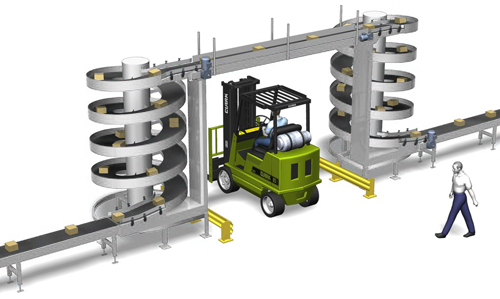

Our Unit Load Spiral Conveyor demonstrates reliable vertical transport for cartons, totes, and other unitized loads. Its compact footprint and high throughput make them a practical solution for packaging operations, warehouses, distribution centers, and e-commerce facilities. It handles loads smoothly while reducing downtime compared to traditional inclines, lifts or elevators.

Our Unit Load Spiral Conveyor demonstrates reliable vertical transport for cartons, totes, and other unitized loads. Its compact footprint and high throughput make them a practical solution for packaging operations, warehouses, distribution centers, and e-commerce facilities. It handles loads smoothly while reducing downtime compared to traditional inclines, lifts or elevators.

We will also showcase our Mass Flow Spiral Conveyor, designed for products in mass, such as cans, bottles, and jars. This Spiral is ideal for high-speed packaging lines, offering gentle handling and efficient transport of multiple products simultaneously. Its design supports both up and down movement, making it a flexible option for beverage, food, and consumer goods operations.

We will also showcase our Mass Flow Spiral Conveyor, designed for products in mass, such as cans, bottles, and jars. This Spiral is ideal for high-speed packaging lines, offering gentle handling and efficient transport of multiple products simultaneously. Its design supports both up and down movement, making it a flexible option for beverage, food, and consumer goods operations.

Finally, visitors will see our Ryson Bucket Elevator. This equipment is built for bulk materials like seeds, powders, and small particulates. Its overlapping bucket design ensures minimal product degradation and prevents spillage, while still maintaining a compact footprint. This makes it a smart solution for industries such as food processing, agriculture, and chemicals.

Finally, visitors will see our Ryson Bucket Elevator. This equipment is built for bulk materials like seeds, powders, and small particulates. Its overlapping bucket design ensures minimal product degradation and prevents spillage, while still maintaining a compact footprint. This makes it a smart solution for industries such as food processing, agriculture, and chemicals.

Together, these three machines highlight Ryson’s broad capabilities in handling unitized loads, mass flow items, and bulk materials. Pack Expo provides the perfect opportunity for attendees to see our equipment in action, learn about their unique advantages, and connect with our experts.

We look forward to welcoming visitors to our booth and demonstrating how Ryson solutions can improve efficiency and productivity across multiple industries.

We hope to see you there! Stop by Booth #W-3570 and see all the machines we have running.

Built to Order, Built to Last: The Art of Ryson Spiral Assembly

How the Ryson Manufacturing Team does Spiral Assembly with Precision and Pride

Our Spiral Conveyor are more than just a product. They are a promise. From the moment a customer places an order to the instant the spiral ships out, our team tracks every variable with laser focus. This dedicated approach ensures each Spiral assembly fits its application perfectly and performs flawlessly.

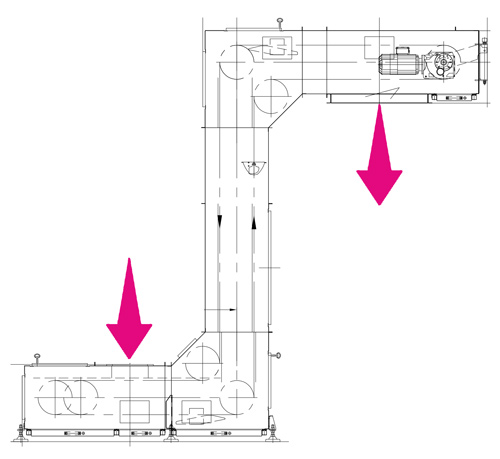

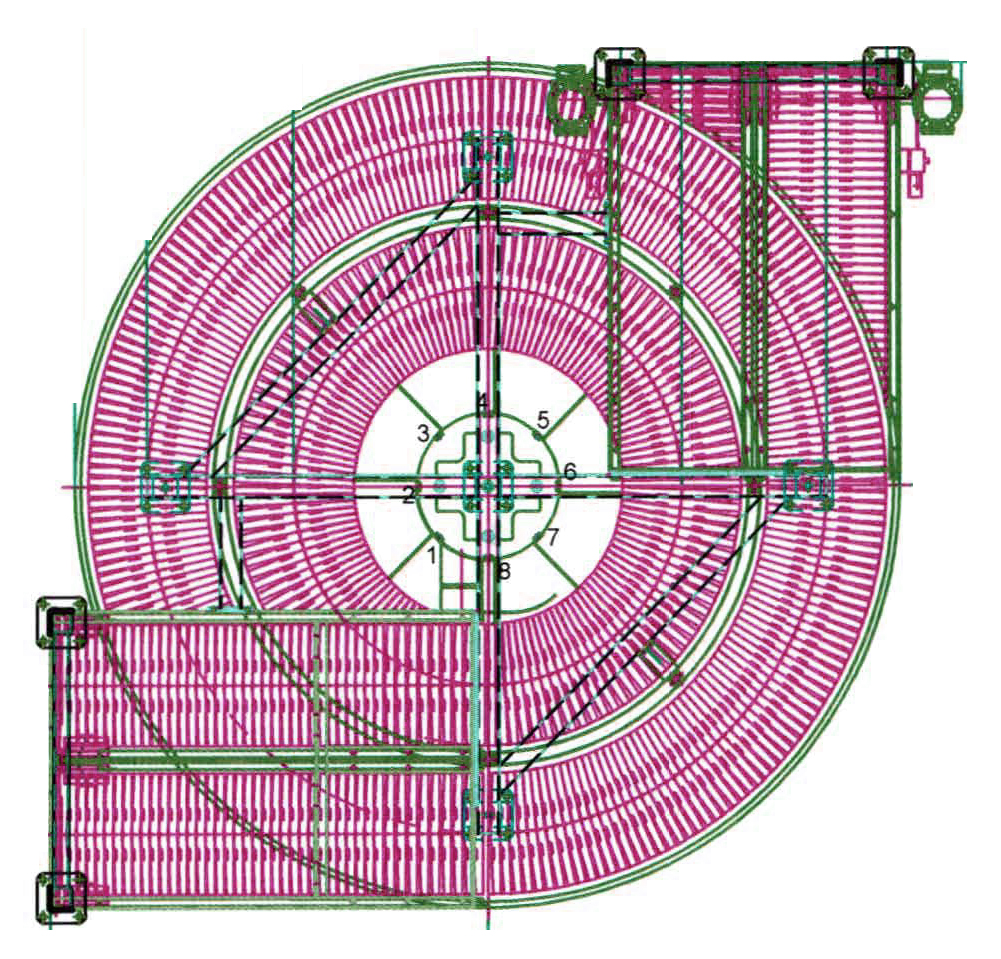

![]() Our process begins with our sales team working directly with our engineering team and the customer. Engineers collaborate on specifications, and refine layouts. Our manufacturing team then readies materials and starts to build. The entire process happens under one roof in Yorktown, Virginia. This tight-knit integration lets us monitor logistics, quality, and schedule from start to finish, ensuring accuracy and accountability at every step of the Spiral assembly process.

Our process begins with our sales team working directly with our engineering team and the customer. Engineers collaborate on specifications, and refine layouts. Our manufacturing team then readies materials and starts to build. The entire process happens under one roof in Yorktown, Virginia. This tight-knit integration lets us monitor logistics, quality, and schedule from start to finish, ensuring accuracy and accountability at every step of the Spiral assembly process.

When manufacturing made-to-order spiral conveyors, we factor in many application variables including:

- Load size, shape, orientation, stability and weight

- Elevation change requirements

- Speeds and throughput

- Adjoining conveyance

- Color/coating

- Clearance from the ground

- Infeed and outfeed tangents

- Footprint of installation area

- Controls options

- Delivery date

Our pride in craftsmanship doesn’t stop in the shop. When not on service calls, our skilled service team members work in the manufacturing area—so they truly know Spirals from the ground up. This dual role also forges deep expertise, and it’s how we uphold reliability standards and streamline preventative maintenance training and support.

The Ryson Brand of Quality:

Ultimately, our integrated teams, engineering, manufacturing, and service, operate in sync to deliver machines built precisely to specification. Every Spiral assembly reflects the dedication and skill of our people. Our equipment is proudly built in Yorktown, Virginia, and many of our components are locally sourced. This helps both our supply chain and our ability to deliver on time. It also means minimal impact from international tariffs.

Ultimately, our integrated teams, engineering, manufacturing, and service, operate in sync to deliver machines built precisely to specification. Every Spiral assembly reflects the dedication and skill of our people. Our equipment is proudly built in Yorktown, Virginia, and many of our components are locally sourced. This helps both our supply chain and our ability to deliver on time. It also means minimal impact from international tariffs.

With a superior product, dedication to highest quality, and close cooperation with our integrators and end customers, Ryson has earned a reputation for delivering high-quality equipment. Our commitment does not end when the spiral leaves our facility—our support continues long after installation, ensuring reliable performance for years to come. This dedication builds trust, and trust leads to satisfied customers. In our experience, satisfied customers are often repeat customers, returning to Ryson because they know we stand behind every spiral we build.

Find out more about our product line, or watch our company video.

Brownfield Integration: Upgrades With Strategic Partnerships

As companies strive to modernize operations without the disruption and cost of building entirely new facilities, brownfield integration has become a powerful solution.

This approach focuses on upgrading existing infrastructure—often replacing aging, space-consuming, and inefficient systems with smarter, more compact equipment. At Ryson, we’ve positioned ourselves at the heart of this movement, offering vertical conveying solutions that not only meet the technical challenges of brownfield environments but also enhance long-term facility performance.

This approach focuses on upgrading existing infrastructure—often replacing aging, space-consuming, and inefficient systems with smarter, more compact equipment. At Ryson, we’ve positioned ourselves at the heart of this movement, offering vertical conveying solutions that not only meet the technical challenges of brownfield environments but also enhance long-term facility performance.

Ryson spiral conveyors are perfect for brownfield integration. Their compact footprint and flexible configurations fit tight spaces with minimal layout changes. Our modular design supports custom infeed and discharge heights. Curved configurations are also available. These features allow smooth integration into nearly any production or distribution environment. That’s especially helpful in facilities with limited space or rigid structures.

Technical complexity is a common concern when retrofitting older facilities, but Ryson’s collaboration with leading system integrators eliminates much of the guesswork. Our equipment arrives ready to integrate, with controls interface options and mechanical design tailored to the integrator’s system architecture. We work closely with our partners from project concept through installation, providing detailed CAD drawings, application engineering support, and fast communication to ensure smooth implementation.

A Collaborative Approach to Vertical Conveyance

This collaborative approach has proven successful time and again. For example, one of our longstanding partnership with Bastian Solutions exemplifies the value of combining vertical conveying expertise with full-system integration. In their article “Material Handling Automation for Existing Facilities,” Bastian explains how brownfield projects can be executed in as little as 6 to 12 months, offering faster ROI and reduced disruption compared to new builds. Their system-level knowledge, combined with Ryson’s compact, reliable spirals, makes for a retrofit solution that maximizes existing space and operational uptime.

As outlined in our own blog post, “Why Ryson Spirals are Ideal for Brownfield Projects,” our equipment’s modularity, small footprint, and ease of installation make it a go-to choice for integrators working on modernization efforts. Whether the project involves replacing inefficient incline belts or rerouting product flow within a legacy warehouse, Ryson spirals streamline the upgrade process—saving both time and space.

The Ryson Advantage

Ryson spirals offer another unique advantage—modularity. You can easily adjust or expand them as your needs evolve. We call this “future proofing.” For example, if you add another level later, you can extend the conveyor height without replacing the entire machine. In most cases, these modifications happen on-site and often take just one day. That keeps downtime minimal and operations running smoothly. This flexibility supports both expected and unexpected future changes, extends equipment lifespan, and helps reduce the total cost of ownership.

![]() Ryson recently published a white paper on upgrading legacy conveyors, and how Ryson Spirals can help increase your throughput and save valuable floor space.

Ryson recently published a white paper on upgrading legacy conveyors, and how Ryson Spirals can help increase your throughput and save valuable floor space.

Ultimately, brownfield integration is about making the most of what you already have while preparing for what’s next. Ryson’s spirals provide a low-risk, high-impact way to elevate facility performance, and our deep collaboration with integrators ensures every solution is not only functional, but optimized for real-world demands. With Ryson, vertical conveying becomes one less thing to worry about—because we’ve engineered it to be the easiest part of your brownfield strategy.

Clear Advantages of Spirals in Food and Beverage Conveying

Strategic Beverage Conveying: How Ryson Spiral Conveyors Deliver Space and Cost Advantages

Beverage production demands throughput, flexibility, and control. As SKU counts climb and plants face both labor and space constraints, conveying systems have become strategic assets. Vertical integration, previously a design afterthought, is now a cornerstone of operational efficiency—and few technologies serve that need better than spiral conveyors.

Ryson Spiral Conveyors, long trusted across the beverage industry, offer a high-value solution for moving product vertically with minimal footprint and maximum uptime. The Case Spiral and Mass Flow Spiral models in particular address critical needs at both ends of the production line—from bulk container handling near the de-palletizer to finished case elevation ahead of palletizing and storage.

Ryson Spiral Conveyors, long trusted across the beverage industry, offer a high-value solution for moving product vertically with minimal footprint and maximum uptime. The Case Spiral and Mass Flow Spiral models in particular address critical needs at both ends of the production line—from bulk container handling near the de-palletizer to finished case elevation ahead of palletizing and storage.

With robust mechanical design, proven reliability, and made-in-America sourcing, Ryson Spirals provide operational resilience and long-term ROI in beverage plants of all sizes.

Additionally, Ryson Spiral Conveyors have a very simple design, making them easy to operate and require very little maintenance. Many Spirals operate in 24/7 environments. Ryson Spiral conveyors answer the demands of reliability, flexibility and high speed.

The Case Spiral: Post-Packaging Efficiency Without the Footprint

The Case Spiral: Post-Packaging Efficiency Without the Footprint

After cases are formed and sealed, getting them efficiently to palletizing or storage becomes a spatial and logistical challenge. In many facilities, floor space is at a premium—especially near the end-of-line where multiple conveyors, robots, and personnel converge.

Compact Elevation, Better Flow

The Ryson Case Spiral reclaims valuable square footage by conveying full cases vertically within a compact footprint. This allows plants to eliminate long, inclined conveyors or catwalks that obstruct traffic lanes and reduce operator mobility. The spiral’s space efficiency simplifies plant layout and clears access aisles for forklifts, AGVs, and sanitation teams.

Line Design Flexibility

Because Ryson Spirals can be configured for elevation changes, bidirectional operation, and custom infeed/discharge points, they integrate cleanly with upstream and downstream equipment. Whether you’re feeding a mezzanine-level automated storage system or transferring to ground-level stretch wrapping, the spiral enables clean transitions without convoluted layouts.

Spiral Conveyors are also much faster than any elevator or lift. The spirals handle products in a continuous flow up to 200 feet per minute. Traditional case elevators can only handle approximately 20 cases per minute. Products of varying sizes can be handled without the need for change parts, minimizing changeover time.

This flexibility is particularly beneficial for plants expanding lines or retrofitting into older infrastructure.

Reliability With Minimal Maintenance

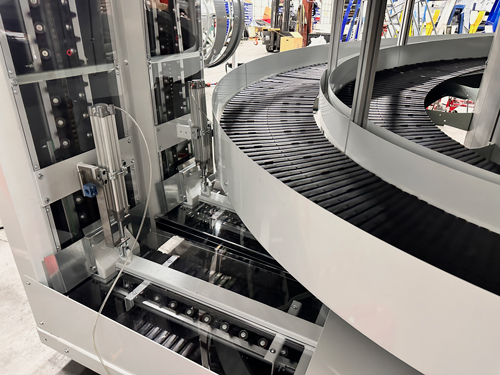

The Case Spiral is engineered to run with minimal intervention. Its robust slat chain, low tension design, and accessible drive system contribute to long service life and high uptime. For end-of-line areas—where failures often have upstream impact—this reliability is crucial.

The Mass Flow Spiral: Seamless Vertical Transport of Jars, Bottles and Cans

Further upstream, the Mass Flow Spiral delivers smooth vertical conveying of bulk containers—typically bottles or cans—between depalletizing, filling, and retort or pasteurization systems. Single-file Mass Flow Spirals can also replace side gripper conveyors ,which need to be adjusted for product changes and require frequent maintenance.

Built for Hygiene and Durability

In food and beverage environments, hygiene is as critical as speed. Ryson spirals are engineered with open construction, slatted chain surfaces, and easily cleanable components. Options like stainless steel and washdown-ready versions are available for sanitary applications, ensuring compliance with industry standards.

Additionally, the spirals are high in mechanical reliability, featuring proprietary chain-slat technology and minimal moving parts. That means reduced maintenance, minimum downtime, and long-term durability—even under 24/7 operational loads.

High-Speed Vertical Transport With Low Footprint

High-Speed Vertical Transport With Low Footprint

Many beverage lines still rely on long, sloped conveyors to lift bulk product to fillers or lower them to accumulation. These systems require space, maintenance, and often introduce bottlenecks.

The Mass Flow Spiral offers a more elegant solution: it elevates or lowers up to 2,000 bottles or cans per minute with controlled flow and gentle handling, all within a footprint smaller than a typical U-turn accumulation loop.

Thermal Process Integration

In facilities utilizing thermal processing—such as retorts, pasteurizers, or chill tunnels—the spiral’s gentle product handling and controlled spacing contribute to consistent dwell times and product quality.

More importantly, Ryson Spirals can be built for operation in cooler and freezer environments, making them ideal for cold-chain applications. Whether transitioning cans into a cold storage tunnel or conveying RTD beverages through frozen buffer storage, these spirals maintain mechanical performance without degradation from low ambient temperatures.

What sets Ryson apart is not just the equipment itself—but how it fits into a plant’s overall strategy. Spirals allow integrators and facility planners to design smarter line layouts, reduce transfer points, and improve product control. In high-speed beverage operations where every second counts, spirals bring the kind of flexibility and dependability that enables facilities to scale efficiently.

And because Ryson products are manufactured in the USA, customers benefit from shorter lead times, robust service support, and a supply chain less prone to disruption.

Investing in Smart Conveying

As beverage and food producers tackle ever-growing demands on space, labor, and product diversity, Ryson Spiral Conveyors provide a proven, space-saving, and future-forward solution. Whether you’re looking to optimize upstream processing, streamline packaging, or elevate finished goods with ease, Ryson offers rugged performance and strategic value to help your line perform at its best.

Want to learn more about how Ryson Spiral Conveyors can enhance your facility? Reach out to our team today to explore the right spiral solution for your operations. Also, check out the video or our YouTube channel in general. Ryson is also a member of Apollo Group, so sales, service and support are completely global through our parent company.

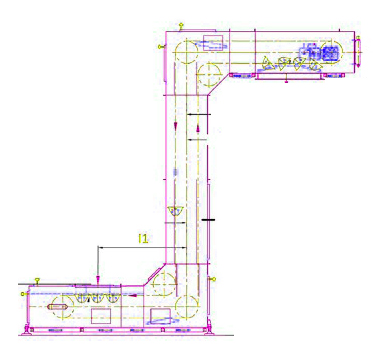

Ryson Bucket Elevator – Horizontal & Vertical Transportation of Bulk Materials

Ryson’s Bucket Elevator continues to prove itself as a flexible and efficient solution for conveying bulk materials.

Ryson’s Bucket Elevator continues to prove itself as a flexible and efficient solution for conveying bulk materials.

Its modular design stands out as a major advantage, delivering adaptability, ease of transport, and simplified on-site assembly — all tailored to meet the specific needs of your application.

This week we are shipping a pair of bucket elevators that will be processing bird seed. The project integrator is Cisco-Eagle. The end user needed to transport birdseed to a hopper that feeds a bagger, for final packaging. The two model 200 units will transport 12,000 bird seed per hour each, with transporting the seed vertically eleven feet.

Cisco- Eagle’s customer needed to upgrade their packaging line so they specified two Ryson Bucket Elevators. They will also gently handle the material so as to reduce breakage and maintain better dust control.

Built to Fit Your Application

Every facility has different layout requirements and material handling needs. That’s why the Ryson Bucket Elevator is engineered with modularity in mind — allowing each unit to be configured to the exact specifications of the customer. Whether your setup calls for multiple infeed points, discharge points, or a unique conveying path, the Ryson Bucket Elevator can be designed accordingly.

This application-specific approach not only ensures seamless integration into your production line. It also minimizes wasted space — an important factor in operations where floor space is limited.

Efficient Shipping and Easy Installation

Another key benefit of the modular design is its impact on logistics. Ryson Bucket Elevators are shipped in sections, making them easier and more cost-effective to transport. Each component is match-marked to assist with fast and accurate reassembly on site.

Another key benefit of the modular design is its impact on logistics. Ryson Bucket Elevators are shipped in sections, making them easier and more cost-effective to transport. Each component is match-marked to assist with fast and accurate reassembly on site.

This modular approach significantly reduces installation time and complexity. Whether you’re setting up in a tight space or coordinating around existing equipment… The Bucket Elevator’s thoughtful design makes the process more manageable.

Built to Handle a Variety of Materials

Versatility isn’t just in the configuration — it’s also in what the Bucket Elevator can handle. Ryson’s solution is ideal for a wide range of bulk materials, including:

-

Fine powders and grains

Fine powders and grains -

Granular and flaky substances

-

Recycled materials and abrasives

-

Glass and other industrial compounds

This makes the Bucket Elevator a trusted choice across industries as diverse as baking and food production, industrial processing, agriculture, recycling, and even scientific or laboratory-based operations.

Designed for Reliability

Whether you’re moving delicate ingredients or rugged recycled goods, the Ryson Bucket Elevator is built for smooth, dependable operation. The gentle handling mechanism ensures product integrity, while the fully enclosed design keeps spillage and contamination in check.

If you’re looking for a bucket elevator that adapts to your space, supports multiple configurations, and handles a wide variety of materials — Ryson’s modular approach might be the perfect fit.

www.ryson.com, download the product information or read other bucket elevator stories on our weekly blog.

From Grocery to Pharma: Industry-Specific Spiral Conveyor Applications

![]()

Spiral conveyors have become indispensable in various industries, offering efficient vertical transport solutions that maximize space and throughput. Their versatility allows them to adapt to different operational needs, temperature ranges, and product handling requirements.

In this article, we explore how spiral conveyor applications are ideal for Ryson Machinery – across some key sectors: Grocery & Food Distribution, Beverage Bottling & Packaging, Cold Chain Logistics, and Pharmaceutical & GMP Facilities.

1. Grocery & Food Distribution

1. Grocery & Food Distribution

Spiral conveyors are used for vertical transport of cases, totes, or trays between picking and shipping areas in grocery and food distribution centers. (Ambient: chilled environments, Examples: food delivery services, cooking box subscriptions etc.)

-

Maximizes throughput even in tight backroom spaces

-

Supports high SKU turnover, enabling efficient handling of diverse product assortments

- Ideally suited for multi-level pick module operations and minimizes floor space in expensive cooler environments.

This application is ideal for grocery operations where space is limited but speed and flexibility are critical to meet consumer demand and maintain inventory flow.

2. Beverage Bottling & Packaging

2. Beverage Bottling & Packaging

- Mass-flow spiral conveyors transport bottles and cans between filling, packaging. Up to 2,000 bottles or cans per hour.

-

They handle high volumes with a minimal footprint, optimizing floor space

-

Supports line flexibility and vertical accumulation, allowing smooth integration into complex packaging systems

This use case is essential for beverage manufacturers aiming to maintain high throughput while ensuring product safety and line adaptability.

3. Warehousing / Logistics / eCom

3. Warehousing / Logistics / eCom

Spiral Conveyors also have become and indispensable part of warehouses and modern DCs. They move boxes, totes, and parcels between multi-level mezzanines, storage, and shipping docks. Their space-saving design helps maximize storage density and streamlines order fulfillment in high-volume distribution centers and automated warehouses. They are also perfect for vertical expansion projects.

- Can introduce or divert product from multiple levels

- Simple integration with existing structures and conveyors

- Can handle large and heavy loads

4. Cold Chain

Spiral conveyors move frozen or refrigerated goods between storage areas and loading docks in cold chain logistics operations. Accommodating subzero environments down to -40°F

-

Maintains product integrity by operating efficiently in cold conditions

-

Energy-efficient design reduces operational costs in temperature-controlled settings

- “One size fits all” conveying, offering a smooth and consistent conveying surface for varied sizes and shapes.

Cold chain logistics benefit greatly from spiral conveyors that preserve product quality while ensuring timely and efficient movement of goods.

5. Pharmaceutical Manufacturing

Used for conveying packaged medicines, vials, or components between levels in pharmaceutical manufacturing facilities.

-

Low power consumption, minimal maintenance and gentle product handling

- Our smallest Spirals, the Narrow Track can handle smaller packages reliably, like blister packs and vials, etc.

-

Integrates seamlessly with automated storage and retrieval systems

In pharmaceutical settings, spiral conveyors offer high-speed conveying while ensuring safe, gentle and efficient product handling in a small footprint.

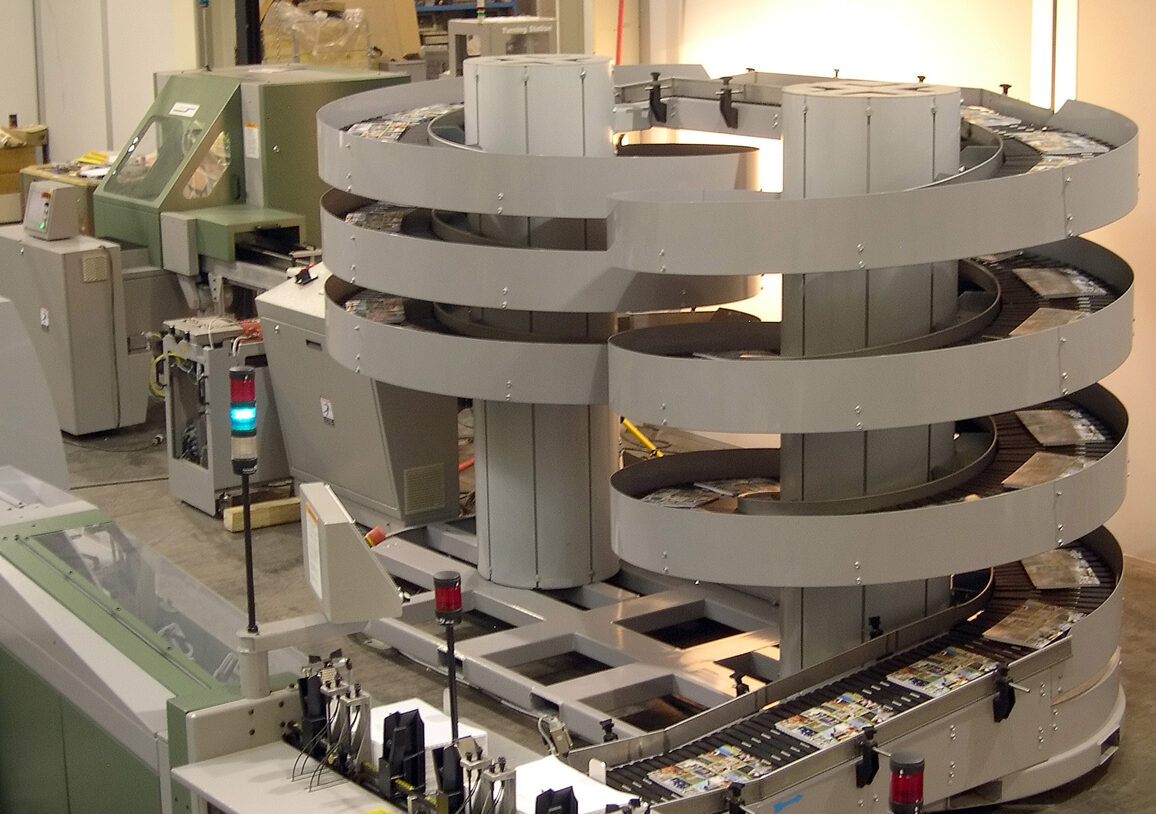

6. Printing & Publishing

6. Printing & Publishing

Ryson Spirals are being used in conveying newspapers, magazines, or printed materials from presses to binding, stitching, or packaging lines. Using spirals maintains product orientation and continuity, supporting high-speed end-of-line operations.

- Can run at slow speeds for drying or curing

- Can provide vertical accumulation

| Sector | KPI (cases/h) | °F Range | Key Benefit |

|---|---|---|---|

| Grocery | 1,500 | Ambient–40°F | High throughput, tight spaces |

| Beverage | 2,000 | 35–100°F | Volume, flexibility, accumulation |

| Cold Chain | 800–1,200 | -20–40°F | Product integrity, energy savings |

| Pharma | 400–800 | 60–75°F | Gentle, small products, reliable |

Spiral conveyors demonstrate remarkable adaptability across industries, from the fast-paced grocery sector to the highly regulated pharmaceutical field. Their ability to operate under diverse temperature conditions and handle varying product volumes makes them a vital component in modern material handling systems, driving efficiency and reliability in supply chains worldwide. You can find more application examples on our own YouTube Channel.

Ryson Spirals Offer Substantial Space Savings Compared to Conventional Incline Conveyors

Ryson Spiral Conveyors have a very small footprint and save more space than conventional incline and decline conveyors. Ryson Vertical Conveying Solutions clearly utilize space more effectively as illustrated in the below comparison. Spirals allow expansion within an existing facility or can reduce the size of a new building.

How Ryson Spiral Conveyors Outperform Traditional Incline Conveyors

Today’s industrial landscape is all about maximizing floor space and of course maximizing ROI’s. As companies strive to optimize their operations, the choice of conveyor systems can have a significant impact on both productivity and facility layout. At Ryson, we understand these challenges and offer innovative spiral conveyor solutions that deliver substantial space savings compared to traditional incline conveyors.

The Space Challenge with Traditional Incline Conveyors

Traditional incline conveyors are commonly used to move products between different elevations. However, they come with several space-related drawbacks:

- Extended Footprint: To achieve a gentle incline suitable for product handling, these conveyors often require long, sloped runs, consuming valuable floor space.

- Limited Flexibility: Their linear design restricts placement options and can complicate facility layouts, especially in tight or irregularly shaped areas.

- Obstructed Workflow: The large footprint can interfere with pedestrian traffic, equipment access, and other operational flows.

Ryson Spirals: The Compact Solution

Ryson Spiral Conveyors are engineered to address these challenges by moving products vertically in a continuous, compact spiral. Here’s how they deliver superior space efficiency:

1. Vertical Elevation in a Small Footprint

Ryson Spirals elevate products vertically, allowing for significant elevation changes within a fraction of the floor space required by traditional incline conveyors. The compact, vertical design enables installation in areas where space is at a premium, even in corners or between existing equipment.

2. Optimized Facility Layouts

2. Optimized Facility Layouts

By reducing the conveyor’s horizontal reach, Ryson Spirals help maintain open aisles and clear workspaces, supporting safer and more efficient operations. The spiral design can be easily integrated into new or existing production lines without major modifications to facility layouts.

3. Real-World Space Savings

Consider a scenario where products need to be elevated by 10 feet.

A traditional incline would require 30-40 ft linear length to move a product 10ft high.

A Ryson Spiral will use 4-8 ft (diameter).

This comparison highlights how Ryson Spirals can reduce the required floor space by up to 80-90%, freeing up valuable real estate for other operations or future expansion.

Additional Benefits Beyond Space Savings

- Continuous Flow: Ryson Spirals provide smooth, uninterrupted product flow, reducing jams and downtime.

- Energy Efficiency: The compact design often requires less power to operate, contributing to lower operational costs.

- Low Maintenance: Fewer moving parts and a robust design mean less maintenance and higher reliability.

Choosing Ryson Spiral Conveyors is a smart investment for companies looking to maximize their facility’s efficiency. By offering substantial space savings, flexible integration, and reliable performance, Ryson Spirals help businesses stay competitive in a space-conscious world. Our Spirals not only save space, they are shipped in one piece, pre-assembled and pre-tested — dramatically reducing the time and expense of installation. Only one drive motor is required, resulting in substantial savings in energy, electrical wiring, controls and system integration.

Click here to download more information about how Ryson can save space in your production area, or visit www.ryson.com. You can also read more ways that Ryson can help lower your total cost of ownership in our weekly blog. Find educational videos on YouTube, too.

New Dual 500 Spiral – High Throughput, Small Footprint

Introducing the Ryson Dual 500: Our Largest Dual Track Spiral Conveyor Yet

Ryson International proudly introduces the Dual 500, the newest and largest model in our Dual Track line.

Ryson International proudly introduces the Dual 500, the newest and largest model in our Dual Track line.

The Dual Track 500 delivers unmatched compact efficiency and flexibility for vertical conveying.

Our Integrator Partner, Van Doren Sales, specified our 1600-500/2800-500 Dual Track Spiral Conveyor to fit a tight space where they needed to lower boxes of fruit from two production lines down to a floor-level sorting system. This two-lane configuration saved significantly more space than installing two separate spirals. The system will handle 60 boxes per minute, operating at 150 feet per minute.

Van Doren also incorporated our multiple-infeed spiral model HC1700-600 to combine three lines into one using an inclining spiral conveyor. One of our technicians visited the site to oversee the reassembly of the dual track spiral and provide startup assistance for the multi-infeed machine.

If you were unaware of our Dual Track line, here are some of the advantages:

Two Independent Spirals in One Frame

Our Dual Track Spirals feature two completely independent spirals within a single compact frame. This smart design allows two separate product lines to share the same footprint. You can run them at different speeds or in opposite directions. Each line stays fully independent.

Our Dual Track Spirals feature two completely independent spirals within a single compact frame. This smart design allows two separate product lines to share the same footprint. You can run them at different speeds or in opposite directions. Each line stays fully independent.

Flexible Multi-Tier Discharge

Each conveying surface can optionally discharge at a different level. This feature adds flexibility for multi-tier operations. You can streamline production lines, reduce transfers, and improve flow.

Continuous Wide Conveying Surfaces

Each track offers a continuous conveying surface that is 20 inches wide. It also allows you to handle a wide range of products with ease; without the need to make adjustments or have down-time for change parts.

Reversible and Independently Driven

Both conveying surfaces have their own drive systems. You can optionally reverse them independently to meet your workflow needs. The Dual 500 adapts to your processes, not the other way around.

Save Valuable Floor Space

Because the Dual 500 combines two spirals into one frame, it takes up far less floor space than traditional vertical conveyors. You can maximize your facility layout without compromising throughput.

Ready to learn how the Ryson Dual 500 can optimize your operations?

Contact us today to discuss your application.

Great opportunity for Bucket Conveying

We are excited to see another Ryson Bucket Elevator shipping. The Bucket conveying project shipping this week is for Industrial Ag Solutions, Inc. As a trusted integrator for clients in agriculture and manufacturing, they’ll use this unit to feed seeds into a dryer before packaging.

We are excited to see another Ryson Bucket Elevator shipping. The Bucket conveying project shipping this week is for Industrial Ag Solutions, Inc. As a trusted integrator for clients in agriculture and manufacturing, they’ll use this unit to feed seeds into a dryer before packaging.

Doug Waldo, the integrator leading the project, explained that the facility already uses several bucket elevators. However, performance issues—especially related to durability and delays in service or part replacement—led them to explore better options. That’s when Doug reached out to Ryson.

Ryson Bucket Elevators are manufactured and shipped from Yorktown, Virginia. We also carry a full inventory of spare and replacement parts. So if there is ever a maintenance issue, we have the parts and a dedicated service team on-hand to get you up and running quickly.

Ryson Bucket Elevators are manufactured and shipped from Yorktown, Virginia. We also carry a full inventory of spare and replacement parts. So if there is ever a maintenance issue, we have the parts and a dedicated service team on-hand to get you up and running quickly.

Ryson’s bucket elevators are a great fit for transporting granular products like seeds. Their fully enclosed design and overlapping buckets help prevent spillage and reduce the risk of cross-contamination. Here is a informative story about Ryson Bucket Conveying recently published in Powder Bulk & Solids.

Ryson’s bucket elevators are a great fit for transporting granular products like seeds. Their fully enclosed design and overlapping buckets help prevent spillage and reduce the risk of cross-contamination. Here is a informative story about Ryson Bucket Conveying recently published in Powder Bulk & Solids.

Why Ryson Bucket Conveying?

Our bucket conveyors are ideally suited to transport granular items, such as seeds because they are completely enclosed and feature overlapping buckets that mitigates spillage and cross contamination. Visit the bucket conveying system section of our website to find out more.

It is also with great pride to announce that Ryson just became a member of PEMA. It is a premier association for North American manufacturers of process equipment, provides members with exclusive access to events, resources, research and a strong network for collaboration and growth. This organization is a perfect place for us to interact with companies that have an interest in our Bucket Elevators.

It is also with great pride to announce that Ryson just became a member of PEMA. It is a premier association for North American manufacturers of process equipment, provides members with exclusive access to events, resources, research and a strong network for collaboration and growth. This organization is a perfect place for us to interact with companies that have an interest in our Bucket Elevators.