How Ryson Spiral Conveyors Contribute To Your Company’s Sustainability Efforts:

In today’s world, companies across most industries are working to reduce waste, improve energy efficiency, and operate more sustainably. Ryson Spiral Conveyors are built with these goals in mind. Not only do they improve production efficiency, but they also have a significant impact on reducing environmental waste. Let’s take a closer look at how Ryson spirals support sustainability.

1. Made Mostly From Recyclable Materials

1. Made Mostly From Recyclable Materials

One of the key ways Ryson Spiral Conveyors contribute to sustainability is through the materials used in their construction. These spirals consist of a blend of aluminum and steel, two of the most recyclable materials on the planet.

- 74% steel: Steel is also highly recyclable, with many industries already repurposing it in various forms. In fact, the majority of steel used today comes from recycled sources. Using steel not only makes Ryson Spirals strong and durable but also ensures that the materials can be repurposed at the end of the equipment’s life.

- 13% aluminum: Aluminum is widely recycled and can be reprocessed over and over without losing its quality. It takes far less energy to recycle aluminum than it does to produce new aluminum, which means less energy consumption and fewer emissions.

- 13% non-recyclable or difficult to recycle materials: In Ryson’s Spiral Conveyors, materials like specialty plastics and rubbers are used sparingly for specific components due to their durability and performance properties, though they are generally harder to recycle. These materials complement the main recyclable components by enhancing flexibility, strength, and resistance where needed in the conveyor design.

By choosing materials that can easily be recycled for the biggest part of our machines, Ryson helps reduce the demand for new raw materials, lowering the overall environmental footprint.

2. Long-Term Flexibility: Reconfigurable Design

2. Long-Term Flexibility: Reconfigurable Design

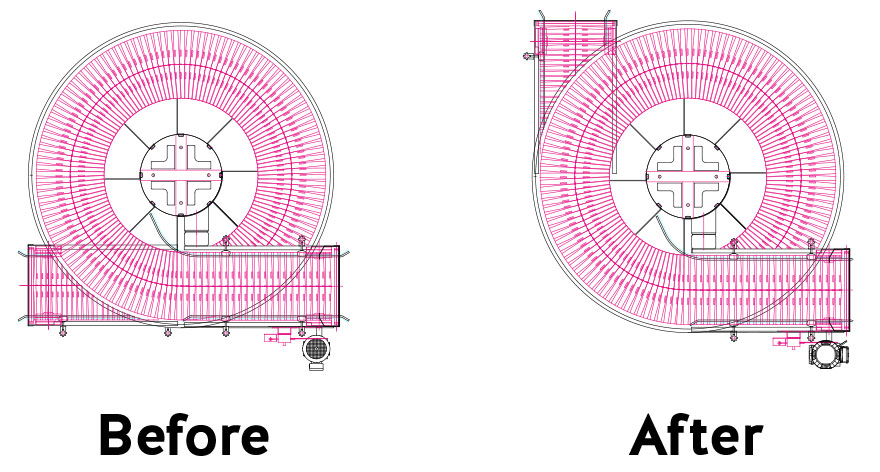

Another major sustainability advantage is the reconfigurable design of our Spiral Conveyors. Rather than discarding equipment when production needs change, these conveyors can be reconfigured to fit new layouts or requirements. This feature means that companies don’t have to throw away old equipment when updating their systems. Instead, they can adjust their existing Ryson spirals to meet new demands.

This reduces waste, as companies can keep using the same conveyors for years, rather than replacing them. It also saves on resources that would otherwise be used to manufacture and ship new equipment.

3. Sustainability & Energy Efficiency

Spiral conveyors are more energy-efficient compared to other material handling systems. Ryson’s design allows for continuous flow with minimal energy consumption, meaning you can move products with less power. This is especially useful in industries where production lines are running constantly, such as in food and beverage production.

The spiral design reduces the need for lifts or heavy-duty conveyors that use more energy, which lowers both the operational costs and the overall environmental impact.

4. Space-Saving Means Less Resource Use

4. Space-Saving Means Less Resource Use

By using vertical space, Ryson Spiral Conveyors save a significant amount of floor space compared to traditional conveyor systems. This can lead to smaller facilities or more efficient use of existing spaces. Smaller facilities mean fewer resources are required for heating, cooling, and lighting. Additionally, the compact design can reduce the need for other equipment, contributing to a smaller environmental footprint.

5. Lower Maintenance Needs

Ryson spirals are designed to be durable and require low maintenance. This means fewer replacements and repairs, further reducing the need for additional materials or resources. Long-lasting equipment is a key factor in minimizing waste in manufacturing and distribution environments.

Conclusion: Small Changes, Big Impact

Choosing sustainable equipment is an important step toward reducing your company’s environmental impact. Ryson Spiral Conveyors stand out by using recyclable materials, offering a flexible and long-lasting design, and improving energy efficiency. These features not only help businesses operate more sustainably but also contribute to lower costs and higher efficiency in the long run.