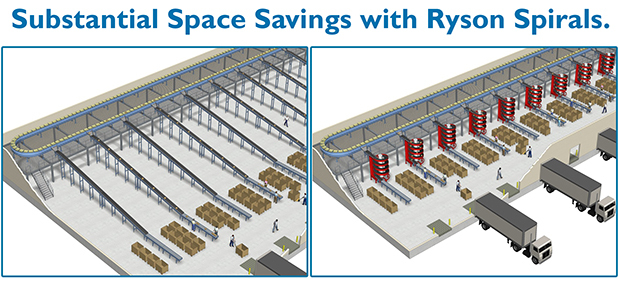

Ryson Spiral Conveyors have a very small footprint and save more space than conventional incline and decline conveyors. Ryson Vertical Conveying Solutions clearly utilize space more effectively as illustrated in the below comparison. Spirals allow expansion within an existing facility or can reduce the size of a new building.

Ryson Spiral Conveyors also have a smaller footprint than conventional belt spiral lifts which need a much larger diameter to operate.

Ryson Spirals not only save space, they are shipped in one piece, pre-assembled and pre-tested — dramatically reducing the time and expense of installation. Only one drive motor is required, resulting in substantial savings in energy, electrical wiring, controls and system integration.

Click here to download more information about how Ryson can save space in your production area, or visit www.ryson.com. You can also read more ways that Ryson can help lower your total cost of ownership in our weekly blog.