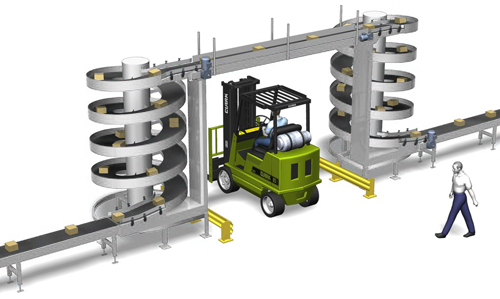

Ryson Spiral Conveyors have a very small footprint and save more space than conventional incline and decline conveyors. Ryson Vertical Conveying Solutions clearly utilize space more effectively as illustrated in the below comparison. Spirals allow expansion within an existing facility or can reduce the size of a new building.

How Ryson Spiral Conveyors Outperform Traditional Incline Conveyors

Today’s industrial landscape is all about maximizing floor space and of course maximizing ROI’s. As companies strive to optimize their operations, the choice of conveyor systems can have a significant impact on both productivity and facility layout. At Ryson, we understand these challenges and offer innovative spiral conveyor solutions that deliver substantial space savings compared to traditional incline conveyors.

The Space Challenge with Traditional Incline Conveyors

Traditional incline conveyors are commonly used to move products between different elevations. However, they come with several space-related drawbacks:

- Extended Footprint: To achieve a gentle incline suitable for product handling, these conveyors often require long, sloped runs, consuming valuable floor space.

- Limited Flexibility: Their linear design restricts placement options and can complicate facility layouts, especially in tight or irregularly shaped areas.

- Obstructed Workflow: The large footprint can interfere with pedestrian traffic, equipment access, and other operational flows.

Ryson Spirals: The Compact Solution

Ryson Spiral Conveyors are engineered to address these challenges by moving products vertically in a continuous, compact spiral. Here’s how they deliver superior space efficiency:

1. Vertical Elevation in a Small Footprint

Ryson Spirals elevate products vertically, allowing for significant elevation changes within a fraction of the floor space required by traditional incline conveyors. The compact, vertical design enables installation in areas where space is at a premium, even in corners or between existing equipment.

2. Optimized Facility Layouts

2. Optimized Facility Layouts

By reducing the conveyor’s horizontal reach, Ryson Spirals help maintain open aisles and clear workspaces, supporting safer and more efficient operations. The spiral design can be easily integrated into new or existing production lines without major modifications to facility layouts.

3. Real-World Space Savings

Consider a scenario where products need to be elevated by 10 feet.

A traditional incline would require 30-40 ft linear length to move a product 10ft high.

A Ryson Spiral will use 4-8 ft (diameter).

This comparison highlights how Ryson Spirals can reduce the required floor space by up to 80-90%, freeing up valuable real estate for other operations or future expansion.

Additional Benefits Beyond Space Savings

- Continuous Flow: Ryson Spirals provide smooth, uninterrupted product flow, reducing jams and downtime.

- Energy Efficiency: The compact design often requires less power to operate, contributing to lower operational costs.

- Low Maintenance: Fewer moving parts and a robust design mean less maintenance and higher reliability.

Choosing Ryson Spiral Conveyors is a smart investment for companies looking to maximize their facility’s efficiency. By offering substantial space savings, flexible integration, and reliable performance, Ryson Spirals help businesses stay competitive in a space-conscious world. Our Spirals not only save space, they are shipped in one piece, pre-assembled and pre-tested — dramatically reducing the time and expense of installation. Only one drive motor is required, resulting in substantial savings in energy, electrical wiring, controls and system integration.

Click here to download more information about how Ryson can save space in your production area, or visit www.ryson.com. You can also read more ways that Ryson can help lower your total cost of ownership in our weekly blog. Find educational videos on YouTube, too.