Each Ryson Spiral is a custom order. This allows the most flexibility and helps optimize your product flow needs. Our proprietary modular design makes this a simple process. It also allows future modifications if the need arises.

The elevation change is only 3’ feet and the footprint per spiral is less than 7.5 feet. This is a critical benefit when real estate and space are a challenge.

Ryson International partnered up for the first time with MHS Global, a well-respected integrator in the US. This application was designed for a long-time client and major player in the storage and material handling industry in Georgia.

Custom Spiral Design:

Custom Spiral Design:

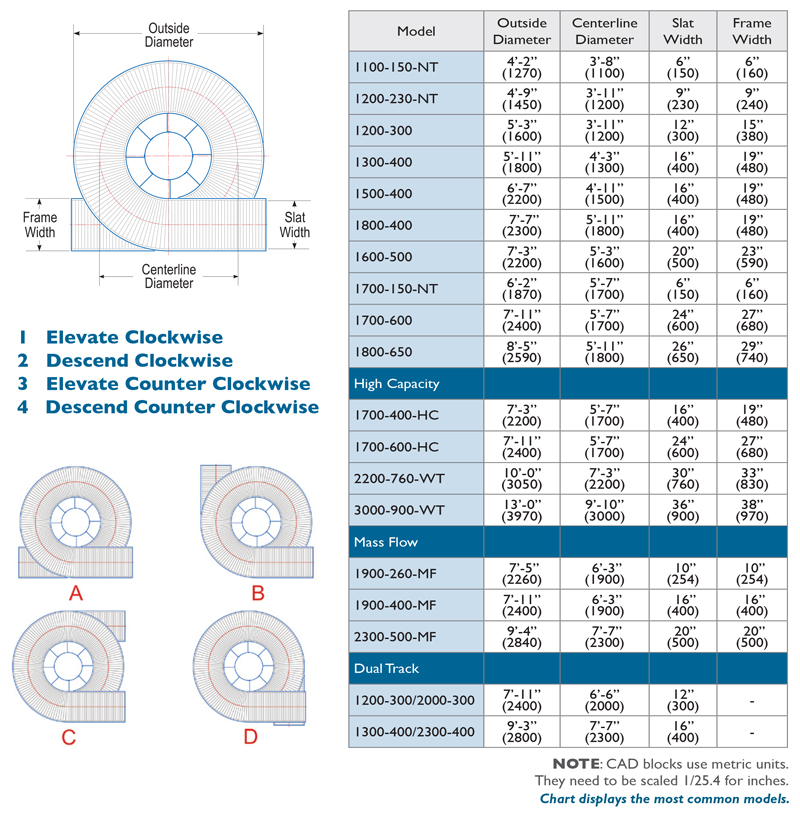

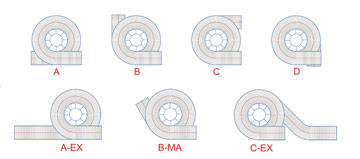

The outside diameter of our spirals is dictated by our one of our 11 different slat widths. Everything else is customer specified. Therefore each custom order Spiral can have unique infeed and outfeed elevations, angle of incline, infeed and outfeed tangents, speed and direction of rotation. Even custom colors can be specified.

The position and length of the in feed tangent on up spirals and out feed tangent on down spirals can be customized to meet specific layout requirements. See the samples shown above (A-EX, B-MA and C-EX).

You can refer to our spiral model chart to find out more specifics about their dimensions. Download it here. For more information about our full line of vertical conveying solutions, visit ryson.com. You can also read current application stories about custom spirals on our weekly blog.