Most Ryson Spirals need very little oiling, but for wash down environments, we can supply custom oilers to replenish the lubrication washed away from cleaning.

We recently shipped this stainless steel washdown rated spiral conveyor Model 1700-600 spiral to a pork processing plant for our Integrator partner, Advanced Equipment. The spiral inclines from 2’ up to a discharge height of over 17 feet and handles cases weighing 60 lbs. at a speed of 180 FPM.

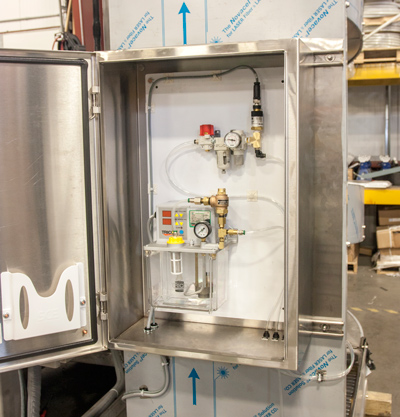

Because the spiral is in the processing area of the plant, it is cleaned nightly just like the sanitized equipment upstream. Consequently, we furnished the pre-wired spiral in all stainless steel with NEMA 4X controls and with our solid lube bearings. After the cleaning event, our control system energizes an automatic oiler (housed in a NEMA 4X enclosure) to re-apply lubricant to the drive chain, as the detergent dissolves it when the spiral is foamed down.

For aggressive wash-down requirements, we recommend using our stainless steel bearings with a new proprietary solid lubricant which is impervious to detergents, mild acids and bases. These bearings have no seal and can run completely immersed in water at any temperature and still provide lubrication for the life of the bearings. Such spirals will also be equipped with an automatic oiler to re-lubricate the chain assembly after cleaning.

You can find out more information about custom spirals on our website, and read more about wash down application stories on our weekly news blog.