Ryson’s Bucket Elevators combine vertical and horizontal transportation of bulk materials in one integral unit. Their modular design is uniquely suited for complex conveying challenges.

Ryson’s Bucket Elevators combine vertical and horizontal transportation of bulk materials in one integral unit. Their modular design is uniquely suited for complex conveying challenges.

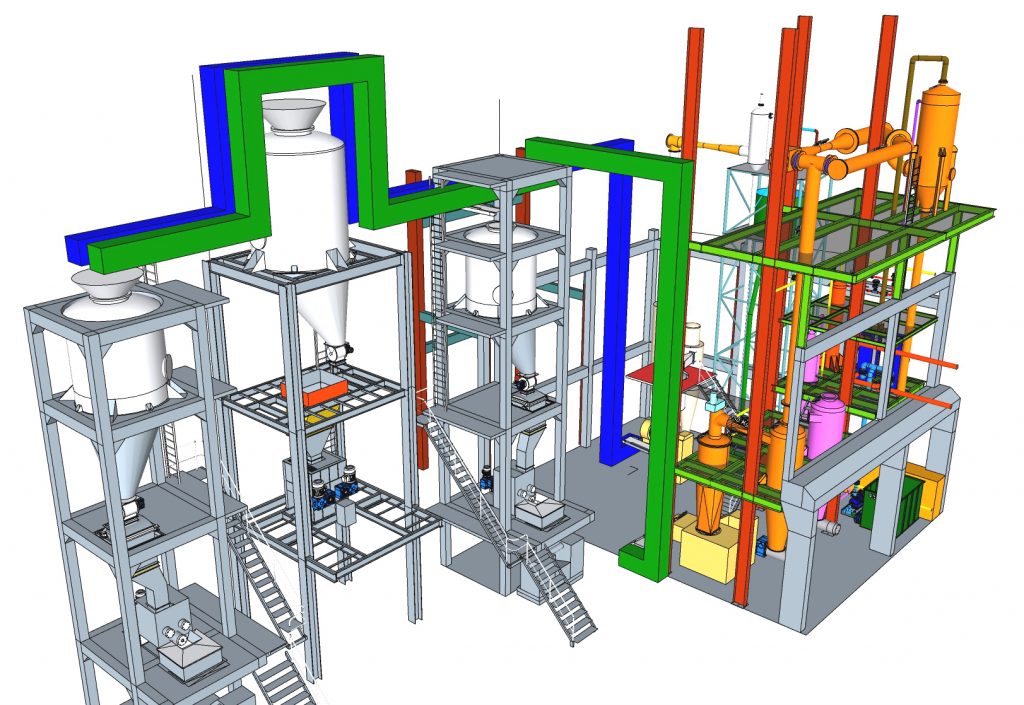

Grupo Cavallaro, a leading producer in South America of detergents, cleaners, and personal hygiene products, chose to implement the Ryson type 200 Bucket Elevator in their process to produce soap pellets. The challenge was that the elevator not only had to convey 11,000 lb/hr of pellets vertically but also, to convey them horizontally, then vertically again, then horizontally, then back down to its final discharge point all in what we refer as a ‘Double-Z’ design.

This was necessary to allow the product to be discharged at 3 separate outfeed points AND at different elevations. The modular design of the Ryson Bucket Elevator is ideal for applications like this… Where there are multiple infeeds and/or multiple outfeeds… Making them uniquely positioned for this kind of application.

The multiple outlets are actuated by using pneumatic cylinders, so that when programmed and activated they will engage the tipping cam and allow the respective bucket to tip at a designated point.

The Ryson series Z-200 elevator can easily handle the required volume. In fact it can handle far more if their production demands increase. The Ryson Bucket Elevators are available with three different bucket sizes, yielding capacities up to 300, 700 or 1800 cubic feet per hour respectively.

Our Bucket Elevators’ robust and forward-thinking design combines a number of features — From gentle handling and rugged construction to minimal maintenance and modular design — businesses have come to benefit from and deeply value. For more information, visit our products pages on ryson.com for Bucket Elevators. You can also read more application stories on our weekly news blog, or download the spec sheet.