Ryson Spiral Conveyors with Induction Conveyors at intermediate levels can be used several different ways. Batch Induction is an efficient way to assure a constant flow from several levels.

Ryson Spiral Conveyors with Induction Conveyors at intermediate levels can be used several different ways. Batch Induction is an efficient way to assure a constant flow from several levels.

In this case, A single spiral was used to send picked boxes overhead to the shipping area in a separate part of the building. Our Integrator Partner Conveyor Handling Company worked with our design team to streamline this efficient solution for a convenience store distribution center in Pennsylvania.

Integrated traffic controls are required for all Multiple Entry and Exit Spirals. Larger gaps need to be left before and after loads entering on different levels. This will prevent collisions between loads, and can result in jams that can damage product and/or the spiral.

Integrated traffic controls are required for all Multiple Entry and Exit Spirals. Larger gaps need to be left before and after loads entering on different levels. This will prevent collisions between loads, and can result in jams that can damage product and/or the spiral.

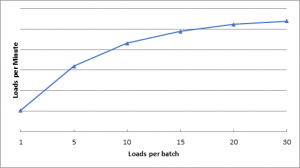

This “traffic control” can significantly reduce the throughput of the spiral if not implemented correctly. One way to improve the throughput is to transport loads in batches from each level. In this scenario larger gaps only need to be left between batches and loads within the batch can be spaced closer together. Although the actual throughput is a function of the length of the load, the throughput with an induction (assuming all loads are the same length) is a curve that is dependent on the number of loads in a batch:

Batching allows a spiral equipped with an induction to achieve throughputs approaching the throughput of the spiral alone. So larger batches result in greater throughput. In a routing type system (loads are coming from one input or another but never more than one in the same period of time that throughput is measured) the throughput is the same as a spiral running without an induction.

Ryson offers two different types of induction conveyors, depending on the type and size of loads to be handled. The belt type design has multiple belts of different lengths. The roller type utilizes powered rollers. Both designs match the spiral radius and are adjustable to match the pitch of the spiral, assuring a safe and reliable product transfer.

Ryson offers two different types of induction conveyors, depending on the type and size of loads to be handled. The belt type design has multiple belts of different lengths. The roller type utilizes powered rollers. Both designs match the spiral radius and are adjustable to match the pitch of the spiral, assuring a safe and reliable product transfer.

The multiple entry and exit spirals are equipped with slats that have special rounded friction inserts. They provide just enough friction to prevent products from back sliding without preventing smooth side movement during induction or diverting out. There are some limitations with regards to the placement (location) of these ancillary conveyors so we encourage you to contact the Ryson sales team for layout assistance early in your project.

Find out more information on Ryson’s Multi-Level Spirals, or read current application stories on our weekly news blog.