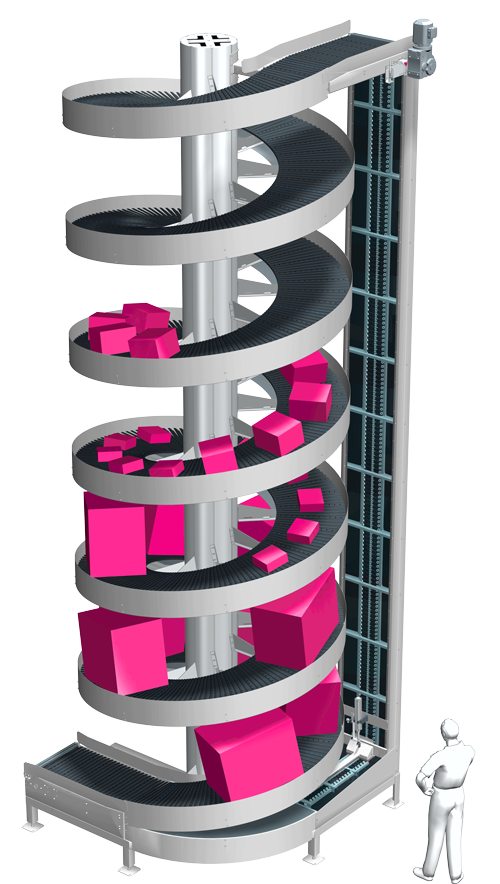

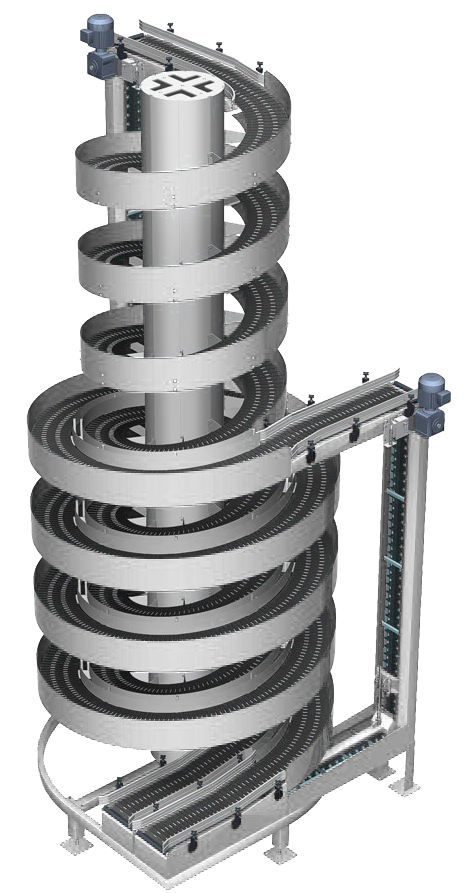

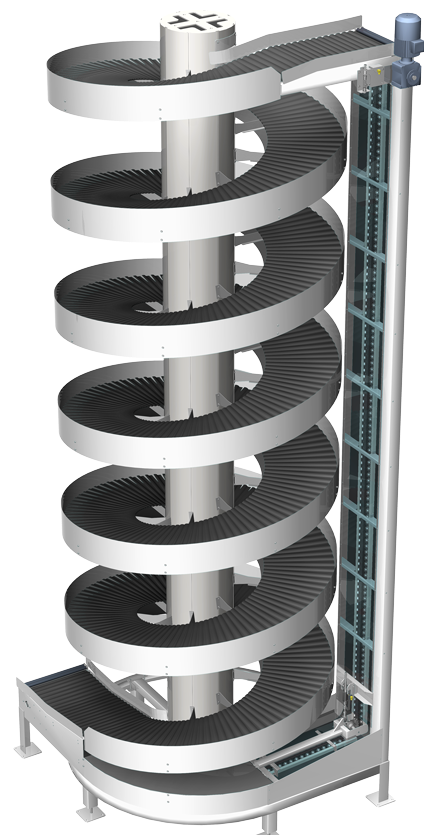

Ryson is the Number One Manufacturer of Spiral Conveyors in the USA

"*" indicates required fields

300 Newsome Drive

Yorktown, VA 23692

(757) 898-1530

sales@ryson.com