Spiral Conveyors Built for Direct to Consumer Warehouses

Ryson Spirals Boost Efficiency in Direct to Consumer Warehousing

Direct to consumer warehousing is growing fast. Brands need smarter ways to move products quickly, handle large order volumes, and use space efficiently. That’s where Ryson Spiral Conveyors come in.

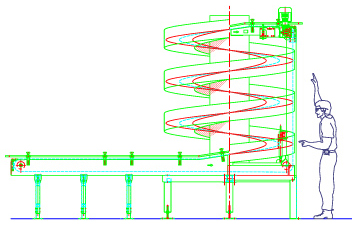

We recently completed a project for a major apparel retailer in Canada. Working with our integration partner Element Logic, we delivered 10 spiral conveyors to their facility. Once installed, these spirals will help streamline operations in a busy direct to consumer warehouse.

Project Snapshot

Project Snapshot

This job included:

-

10 Ryson Model 1900-600 Spiral Conveyors

-

8 units with standard chain, and 2 high-capacity units

-

Elevation changes between 7 and 34 feet

-

Capability to move boxes up to 30″ x 20″

The spirals were chosen for their ability to handle many different product sizes without adjustment. They also help the facility save space and speed up fulfillment.

A Strong Integration Partnership

This project was led by Element Logic, a global warehouse automation company. They recently acquired ABCO Systems, another trusted Ryson partner based in New Jersey. The combined strength and experience of these two companies is a win-win. Both for their customers, and Ryson as a supplier.

The Rise of Direct to Consumer Warehousing

The apparel industry is shifting toward direct to consumer (DTC) models. More companies are shipping products straight to shoppers instead of using stores or resellers. This shift brings new challenges, like:

-

Handling many small orders

- Handles varied shapes and sizes

-

Managing fast-moving inventory

-

Making the most of available space

That’s where Ryson Spiral Conveyors help. They’re built for the demands of modern DTC warehouses.

Why Ryson Spirals Are a Smart Choice

Our spirals offer key benefits:

-

Save space by moving products vertically

-

Support high throughput for busy operations

-

Work well with other warehouse systems

-

Run reliably with low maintenance

-

Use energy efficiently

Ryson Spiral Conveyors are helping companies across industries build better, faster, and more flexible direct to consumer warehouses. This project in Canada is just one example of how we support smarter fulfillment every day.

Ryson Engineering Department Applauding a Big Promotion

David Long steps into the role of Engineering Manager this month. David’s attention to detail and creative approach has added an enthusiastic energy to the Ryson Engineering Department.

Engineering plays a central role at Ryson International, shaping every aspect of our conveying solutions. Our engineering team works closely with our partners to help meet the specific application needs of our customers. From designing custom layouts to integrate into systems, the engineering team ensures that every conveyor delivers long-term performance and reliability. Their dedication upholds Ryson’s reputation for quality, innovation, and space-efficient solutions in the material handling industry.

” This achievement wouldn’t have been possible without Mark Rakentine’s mentorship. His industry expertise and guidance have accelerated my learning beyond what I thought possible. Looking forward, I am committed to maintaining Ryson’s technical excellence while introducing innovative solutions and resources that position us for continued growth. My focus remains on empowering our team and delivering exceptional value to our customers as we evolve with industry demands.” – David Long, Engineering Manager at Ryson.

” This achievement wouldn’t have been possible without Mark Rakentine’s mentorship. His industry expertise and guidance have accelerated my learning beyond what I thought possible. Looking forward, I am committed to maintaining Ryson’s technical excellence while introducing innovative solutions and resources that position us for continued growth. My focus remains on empowering our team and delivering exceptional value to our customers as we evolve with industry demands.” – David Long, Engineering Manager at Ryson.

Mark Rakentine, the previous Engineering Manager, has been grooming David for this position for quite some time. Mark now begins his next chapter as Chief Engineer. In this new position, he will be able to focus his experience more on applications and sales support.

Please join us in congratulating both on their new promotions and the potential it brings to our engineering department!

Why Ryson Spirals are Ideal for a Brownfield Project

Brownfield projects: What they are—and why Ryson Spirals are ideal.

A brownfield project means improving an existing manufacturing plant, warehouse or distribution center instead of building a brand-new facility (a “greenfield”). The goal is to squeeze more capacity, efficiency and speed out of the same four walls with as little downtime, construction work, and capital spend as possible.

There are many reasons that Ryson equipment is ideally suited for a brownfield project. Below are a few points to consider.

Add vertical capacity without eating floor space

Ryson’s compact spiral frame slips into the footprint once taken by a belt incline or vertical lift yet raises cartons and totes as high as 40 feet. By reclaiming those long approach runs, you open up valuable floor area for extra pallet slots, pick modules, or robot aisles—growing storage and throughput without pushing out any walls.

Install fast in tight, busy areas

Ryson Spirals usually ship in one piece. But because of our modular design, a spiral can be specified to ship in manageable modules. Installation crews convey the sections through narrow doors and between live lines, then assemble them together around existing pipes or racks. Because the work happens in small chunks—often during scheduled breaks—operations can stay online and revenue keeps flowing.

Cut energy and maintenance bills

A single low-horsepower motor drives the spiral, replacing several belt-driven units and trimming your energy draw from day one. Our rugged slat-chain needs little service, so you spend less on parts, labor, and downtime over the life of the system…. delivering a lower total cost of ownership every year it runs.

Upgrade to facilitate automation

Upgrade to facilitate automation

The growing trend to increase automation and efficiency is growing. However many older machines are not equipped to handle the demands of automation. Ryson Spirals can also be easily integrated into controls packages.

Handle mixed loads gently

The continuous slat surface conveys poly bags, light cartons, and heavy totes with the same smooth motion. No gaps, transfers, or sudden drops mean fewer jams and less product damage. That also keeps orders on schedule and customers happy. That also means more different SKUs can be conveyed on the same lines, leaving you more flexible for product diversity.

The brownfield project bottom line

Upgrading with a Ryson Spiral Conveyor lets you lift product up to 40 ft high while keeping the project lean:

-

Easy Installation—Most spirals ship in one piece, but even if specified to be reassembled on-site, the installation process is fast and simple.

-

Minimal electrical changes—one drive replaces several belt motors and easily integrates to any system.

-

Rapid return on investment—more throughput and less power draw drop straight to the bottom line.

Whether you’re replacing an aging incline or looking to add a new pick level, Ryson Spirals tick every box a brownfield project upgrade demands. Including a small footprint, quick installation, increased reliability, and long-term savings.

![]() Ryson will be attending the WERC 2025 Annual Conference next week. WERC – Warehouse Education Research Council is an ideal community of warehousing and distribution center professionals. Leading the industry with vision and passion.

Ryson will be attending the WERC 2025 Annual Conference next week. WERC – Warehouse Education Research Council is an ideal community of warehousing and distribution center professionals. Leading the industry with vision and passion.

Why Trade Organizations Matter — And How You Benefit

In an increasingly competitive global market, staying informed, connected, and forward-thinking is more than a luxury—it’s a necessity. At Ryson International, participation in trade organizations is not just about industry presence—it’s a strategic commitment to excellence and innovation. But what does this mean for you, the customer? The answer: quite a lot.

Last week, we had a productive visit with MHI’s Membership Experience Manager – Angela Alston-Jenkins. Her job is to visit with member companies and give detailed information about benefits and opportunities MHI offers that companies aren’t necessarily taking advantage of. We were very impressed with the initiative, and the meeting itself. It also is a win-win because they also learn more about what our company can offer to the industry at-large.

Last week, we had a productive visit with MHI’s Membership Experience Manager – Angela Alston-Jenkins. Her job is to visit with member companies and give detailed information about benefits and opportunities MHI offers that companies aren’t necessarily taking advantage of. We were very impressed with the initiative, and the meeting itself. It also is a win-win because they also learn more about what our company can offer to the industry at-large.

MHI is America’s largest material handling, logistics and supply chain association. They cater to a diverse array of disciplines, and our membership includes professionals ranging from equipment manufacturers, consultants and publishers to third-party logistics providers and systems integrators. MHI has sponsored industry trade events in support of the products and services of its membership for over seventy years.

How Ryson’s Memberships Benefit Our Customers

How Ryson’s Memberships Benefit Our Customers

Ryson International proudly participates in several major trade organizations, including —MHI (Material Handling Industry), PMMI (The Association for Packaging and Processing Technologies), FPSA (Food Processing Suppliers Association), and PEMA (Process Equipment Manufacturers’ Association). These memberships aren’t symbolic; they translate into real advantages for our partners and customers.

✓ Cutting-Edge Solutions Tailored to Market Needs

Our active role in trade groups keeps us at the forefront of material handling and packaging technology trends. When we innovate, it’s not in a vacuum—it’s with real-time insight into evolving industry demands. That means more efficient, space-saving, and reliable spiral conveyor solutions for your operation.

✓ Elevated Quality and Safety Standards

By contributing to standards committees and technical workgroups, Ryson ensures that our equipment meets or exceeds the highest industry benchmarks. This protects your investment and supports safer, more productive environments.

✓ Early Access to Innovation and Trends

Whether it’s a new modular design principle or an automation breakthrough, Ryson is often among the first to explore and adopt new methodologies—giving our customers an early advantage in productivity and system integration.

✓ Stronger Industry Connections

Our involvement opens doors to better collaboration with system integrators, OEMs, and logistics partners—streamlining your projects and fostering seamless supply chain performance.

✓ Advocacy That Protects Your Interests

Through trade organizations, Ryson has a voice in shaping the future of our industry. From tariff discussions to sustainability initiatives, we advocate for policies that benefit our customers and uphold the integrity of global trade.

A Commitment That Goes Beyond Products

Being part of respected trade organizations signals a deeper commitment—not just to our peers, but to our customers. It means we’re not just building Spiral Conveyors; we’re helping shape the future of the industries they serve. At Ryson, we believe your success is our success—and every initiative we join is ultimately about adding value to your operations.

If you’re looking for a material handling partner that is deeply engaged, continually improving, and actively shaping the industry—look no further than Ryson International.

Sharpening How We Work — Apollo Ryson

This week, our Yorktown plant transformed into a live collaboration hub, showcasing the strength of Apollo-Ryson teamwork. We were honored to host our CEO, Claudia van den Pol, visiting from the Netherlands alongside three key leaders from the Royal Apollo Group—our General Manager of corporate office in Coevorden, Holland, CFO, and IT Manager. Their mission? To align our U.S. operations with Apollo’s global vision.

What We Compared—and What We Gained

What We Compared—and What We Gained

The primary focus of their visit was to gain deeper insight into Ryson’s workflows—across sales, engineering, service, spare parts, and IT. But what we truly gained was something more valuable: shared strengths.

By identifying the best practices that already thrive on both sides of the Atlantic—in Yorktown and at our Coevorden headquarters—we avoided duplicating efforts. That lets us channel our energy where it matters most: improving gaps and building efficiency.

Why This Matters on U.S. Soil

-

Faster, Smarter Processes. Streamlined communication between our U.S. and European teams leads to quicker approvals, stronger workflows, and ultimately, a more agile supply chain.

-

A Sustainability Advantage. With Europe ahead of the curve on sustainability and ESG standards, we’re able to bring those proven strategies into the products and services we offer through Ryson in the U.S.—a key differentiator in today’s market.

-

Global Flexibility Amid Economic Uncertainty. As a global company navigating fluctuating tariffs and economic shifts, close coordination enables quick pivots. For instance, our internal alignment could allow us to ship a Spiral from Europe instead of the US if it would mitigate tariffs.

Apollo Ryson Company Culture

Apollo Ryson Company Culture

Claudia’s visit wasn’t just about business. It was also a chance to embody the culture she believes in. Arriving a week early with her daughter Jackie, Claudia balanced running a global company with being a present mom. Jackie could be found doodling in the meeting room or quietly watching her shows while Claudia led strategy discussions.

This isn’t just a sweet anecdote—it’s a statement. Claudia’s message is clear:

This isn’t just a sweet anecdote—it’s a statement. Claudia’s message is clear:

“Processes matter, but people power them. When you honor both family and work, you build a stronger company.”

Read more about us and our company’s values.

Bottom line: Aligning our systems isn’t paperwork—it’s how we keep promises to customers worldwide. Thanks to Claudia, her team, and everyone in Yorktown who made this happen.

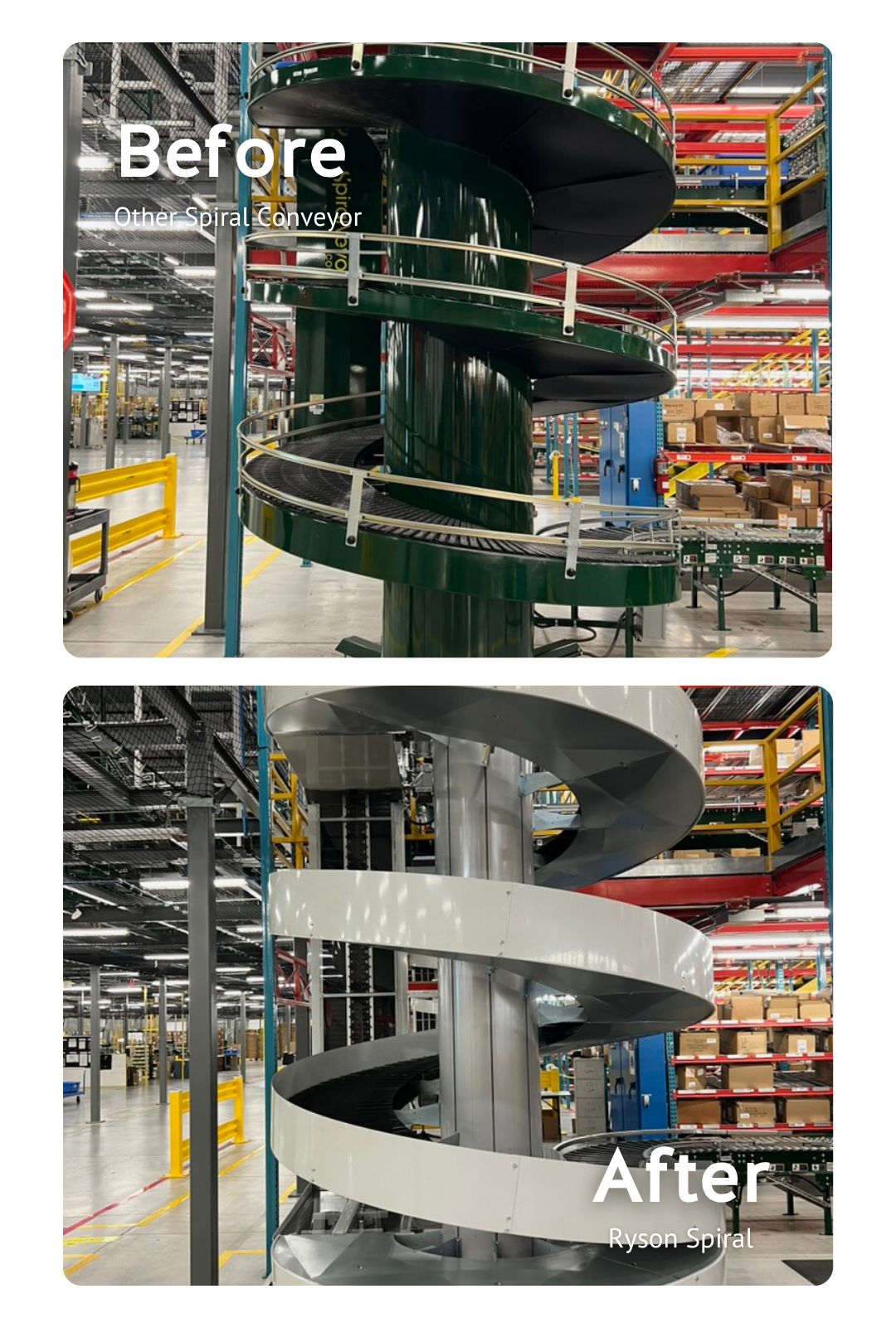

Ryson Spirals Replace Other Vertical Conveying Equipment

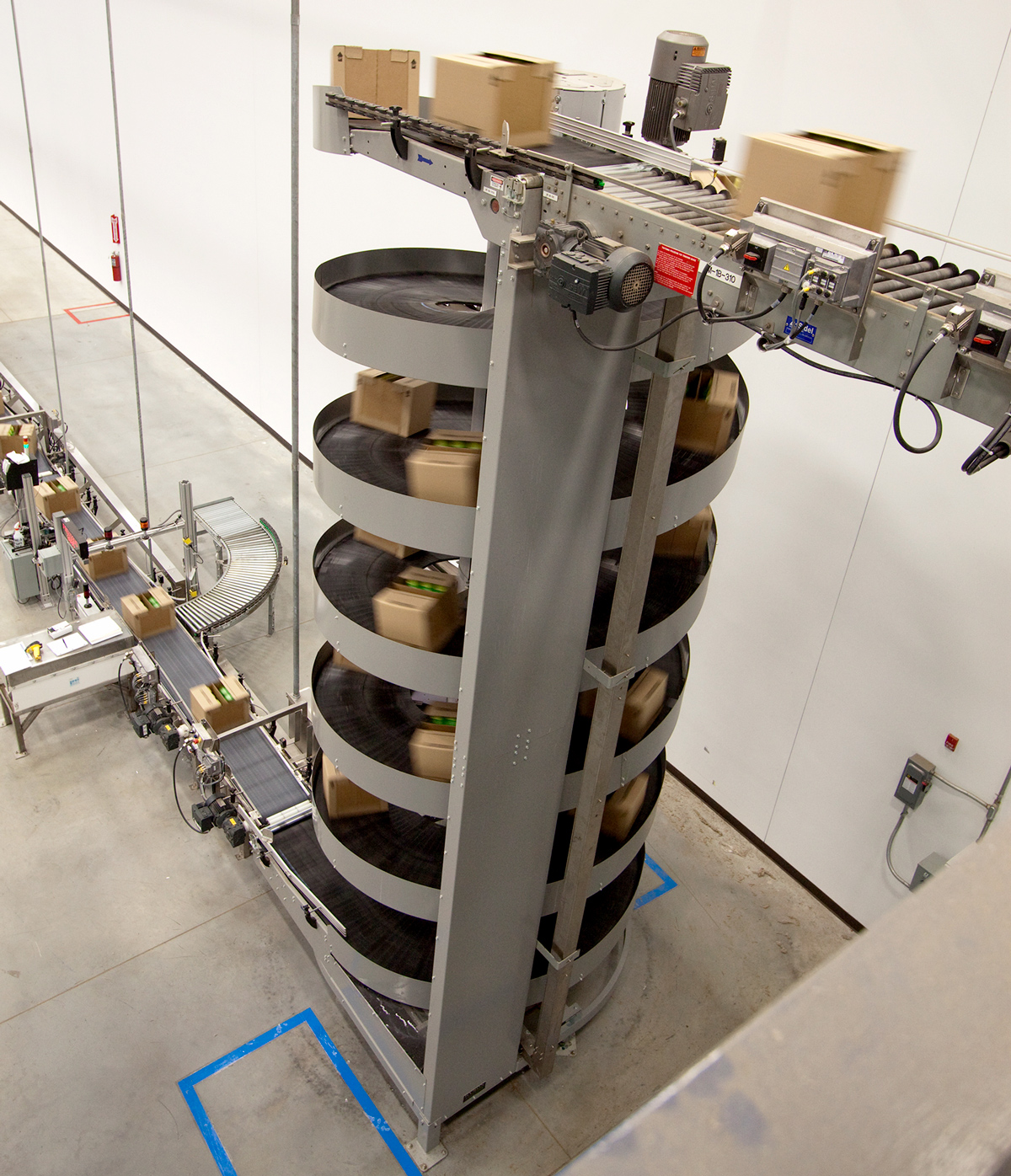

In the recent years, Ryson Spirals have been specified to replace older vertical conveying equipment. Our Spirals perform the same function, but often with more reliability and a smaller footprint. Ryson equipment therefore helps lower the total cost of ownership and increases the ROI. Our machines have been replacing outdated equipment by end-users, and also our integrator partners are finding opportunities for improvement with their customers.

In the recent years, Ryson Spirals have been specified to replace older vertical conveying equipment. Our Spirals perform the same function, but often with more reliability and a smaller footprint. Ryson equipment therefore helps lower the total cost of ownership and increases the ROI. Our machines have been replacing outdated equipment by end-users, and also our integrator partners are finding opportunities for improvement with their customers.

Ryson Equipment stands out for these advantages:

- Vertical conveyance using the smallest footprint possible.

- Achieving a high throughput rather than having a cycle time that hinders performance.

- Reliability with a very high up time. It’s something we bring from our decades of experience in the packaging and manufacturing to the warehousing world.

- Delivering a product that is installation and maintenance friendly

- Operating at low noise levels (under 75 dB) using 1 motor for efficiency and lower energy consumption

- Modularity to help future-proof the equipment

Ryson Spirals Replacing Case Lifts

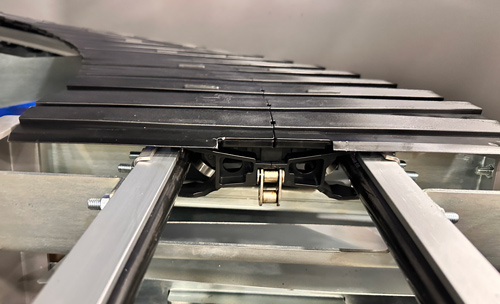

Unlike conventional elevators or lifts, which often require more space and have limited throughput, Ryson Spiral Conveyors provide a compact, high-capacity alternative. They enable faster product movement without the need for stops or waiting, streamlining operations and improving efficiency in vertical product transport. In the first image we see an old case elevator with a low throughput being replaced by a Ryson Spiral for an optimal streamlined and fast process.

Ryson Spirals Replacing Other Spiral Conveyors

Ryson Spirals Replacing Other Spiral Conveyors

Ryson Spirals have been replacing other spirals in the field for years. They stand out from other brands due to their robust construction, modular design and smooth operation. Moreover they are able to a handle high-speed and continuous product flow without interruption. They’re designed to last, reducing maintenance and downtime. Their modularity (our spirals are bolted, not welded) also makes it easy to make field changes and reconfigurations at any time.

All in all they are a valuable upgrade for facilities seeking a more reliable vertical conveying solution.

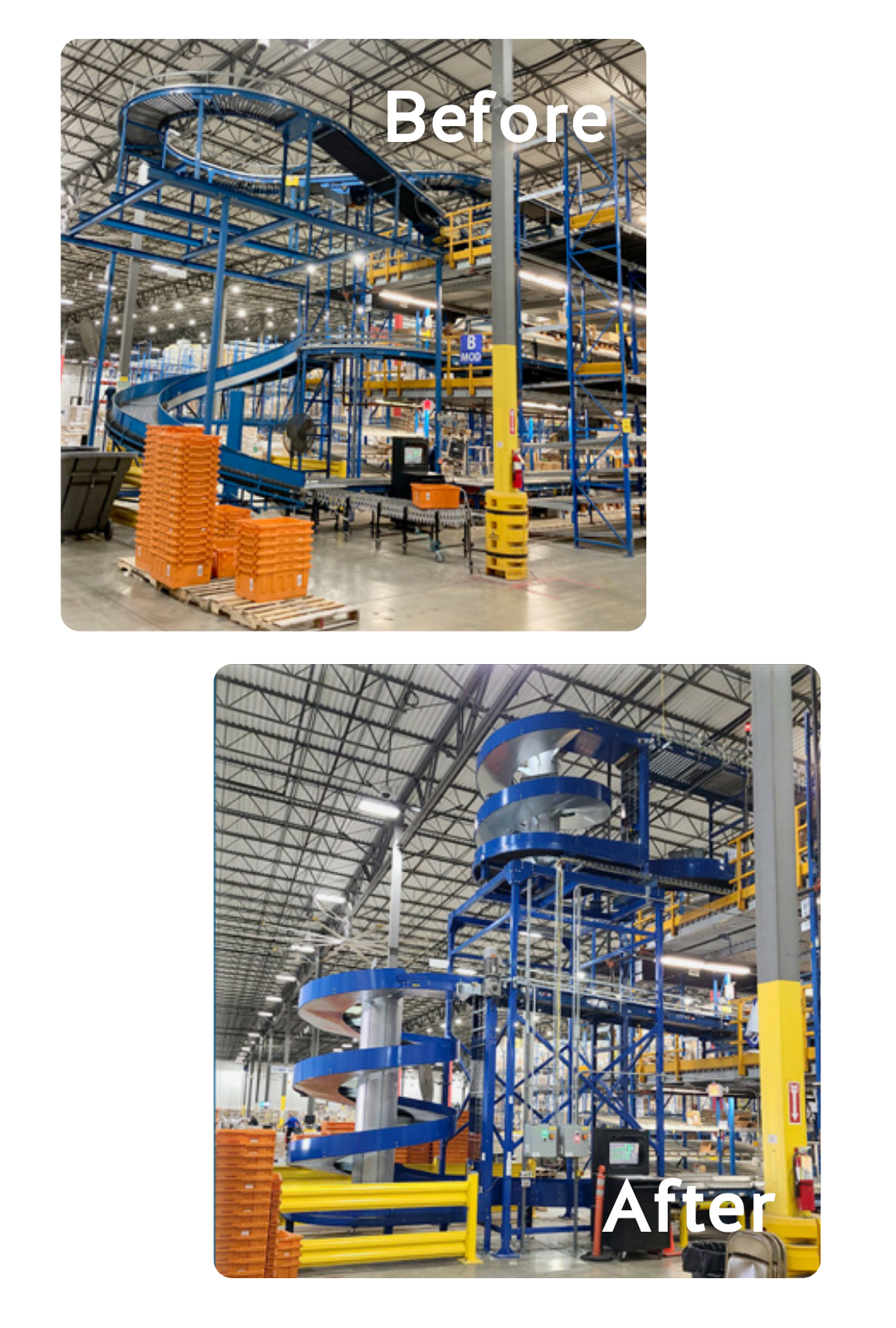

Replacing Curved Conveyors or Gravity Spirals

Replacing Curved Conveyors or Gravity Spirals

In this example, our integrator partner MHS Global with a recommendation from our client Tech Data have teamed up to replace most of their existing vertical conveying equipment and incline belts with Ryson Spirals. The main reason for the upgrade was that the existing equipment was constantly breaking down, which in turn led to a lot of lost time and strain on their maintenance department.

The swap was straight forward, and the integration happened over a weekend. These units were shipped fully assembled (model 1700-600) and will convey a product that is 30” tall. This model can start and stop fully leaded with a maximum capacity of 1,800 lbs. There is also a high-capacity version of these units than can handle up to 3,600 lbs.

For more information or if you have similar challenge, please visit our website and fill in the Request information form.

Ryson Spiral Conveyor Myths Debunked

4 Ryson Spiral Conveyor Myths – Busted

4 Ryson Spiral Conveyor Myths – Busted

Spiral conveyors have become essential equipment in distribution centers, fulfillment hubs, and production lines worldwide, yet a few stubborn misconceptions still surface in conversations with plant managers and engineers. Let’s clear the air. Below are four spiral conveyor myths we hear most often—each one followed by the straight facts.

1. Myth: Products must stay perfectly centered on the conveying surface; otherwise the slats will deflect, break, or jam.

Centering is a recommendation, so that the product exits the Spiral centered. It is not due to the limitations of the slats. Ryson slats are designed with reinforcement to handle the weight distribution of the loads. Even if cartons slide off-center, the chain‑side supports carry the load without creating unsafe stress. Keeping items roughly centered simply removes the need for additional guiding components—nothing more. Ryson Spirals are also capable of transporting products side-by-side because our slats are very rigid and do not easily bend.

Centering is a recommendation, so that the product exits the Spiral centered. It is not due to the limitations of the slats. Ryson slats are designed with reinforcement to handle the weight distribution of the loads. Even if cartons slide off-center, the chain‑side supports carry the load without creating unsafe stress. Keeping items roughly centered simply removes the need for additional guiding components—nothing more. Ryson Spirals are also capable of transporting products side-by-side because our slats are very rigid and do not easily bend.

2. Myth: A spiral made from bolted sections can’t survive a seismic event; the tower will come apart.

Our modular, bolted design is built for seismic zones. The joints lock the column together like segments of a steel spine, allowing the structure to flex within engineered limits rather than crack. That’s one reason California—the most seismically active state in the U.S.—has more Ryson spirals in service than anywhere else. In fact, bolted joints perform better in dynamic loading than welded joints. Multiple real‑world quakes have proven the design again and again.

Our modular, bolted design is built for seismic zones. The joints lock the column together like segments of a steel spine, allowing the structure to flex within engineered limits rather than crack. That’s one reason California—the most seismically active state in the U.S.—has more Ryson spirals in service than anywhere else. In fact, bolted joints perform better in dynamic loading than welded joints. Multiple real‑world quakes have proven the design again and again.

3. Myth: Ryson relies only on an air‑cylinder system to set chain tension, so you must supply compressed air.

3. Myth: Ryson relies only on an air‑cylinder system to set chain tension, so you must supply compressed air.

Air tensioning is one option. For sites without compressed‑air utilities (or where you’d rather keep everything mechanical), we fit a spring tensioner that delivers the same consistent take‑up force. Choosing between air and spring is simply a matter of what works best for your facility, not a limitation of the spiral. We do however recommend using a pneumatic tensioner if the spiral will be reversible, since pressure needs may fluctuate between up and down operation.

Air tensioning is one option. For sites without compressed‑air utilities (or where you’d rather keep everything mechanical), we fit a spring tensioner that delivers the same consistent take‑up force. Choosing between air and spring is simply a matter of what works best for your facility, not a limitation of the spiral. We do however recommend using a pneumatic tensioner if the spiral will be reversible, since pressure needs may fluctuate between up and down operation.

4. Myth: You can’t stop a spiral when fully loaded and expect it to restart without issues.

Ryson spirals are designed to start and stop while fully loaded. The drive package, chain, and slats are sized to handle the static load and the inrush current at start‑up. Many integrators even tie the spiral into scan‑based or zone‑fill controls that halt traffic momentarily—then bring everything back online smoothly. This is also a reason Ryson Spirals don’t require sliding side-support, our design uses a rolling friction support structure, facilitating an easy glide of our chain, and allowing us to start and stop fully loaded. Our High Capacity Spirals can easily start and stop with up to 3,600 lbs. of load.

Ryson spirals are designed to start and stop while fully loaded. The drive package, chain, and slats are sized to handle the static load and the inrush current at start‑up. Many integrators even tie the spiral into scan‑based or zone‑fill controls that halt traffic momentarily—then bring everything back online smoothly. This is also a reason Ryson Spirals don’t require sliding side-support, our design uses a rolling friction support structure, facilitating an easy glide of our chain, and allowing us to start and stop fully loaded. Our High Capacity Spirals can easily start and stop with up to 3,600 lbs. of load.

Key Takeaways

-

Built for real‑world conditions. Slightly off‑center cartons, scheduled stops, and seismic codes are part of everyday material‑handling life; Ryson spirals are engineered with that reality in mind.

-

Flexible by design. Whether you need air or spring tensioning—or both in different areas of the plant—our Spirals are flexible and made to order.

-

Proven track record. Thousands of installations, including hundreds in seismic zones, back up the facts above.

- Lower cost of ownership. Our modular design and highly efficient chain-slat arrangement provides a smooth and reliable conveying surface that requires minimal maintenance. Our Spirals have a proven track record of up-time and longevity.

Have another question or a challenge you’d like solved? Reach out—our applications team is always glad to help. Check out our YouTube channel for some application videos.

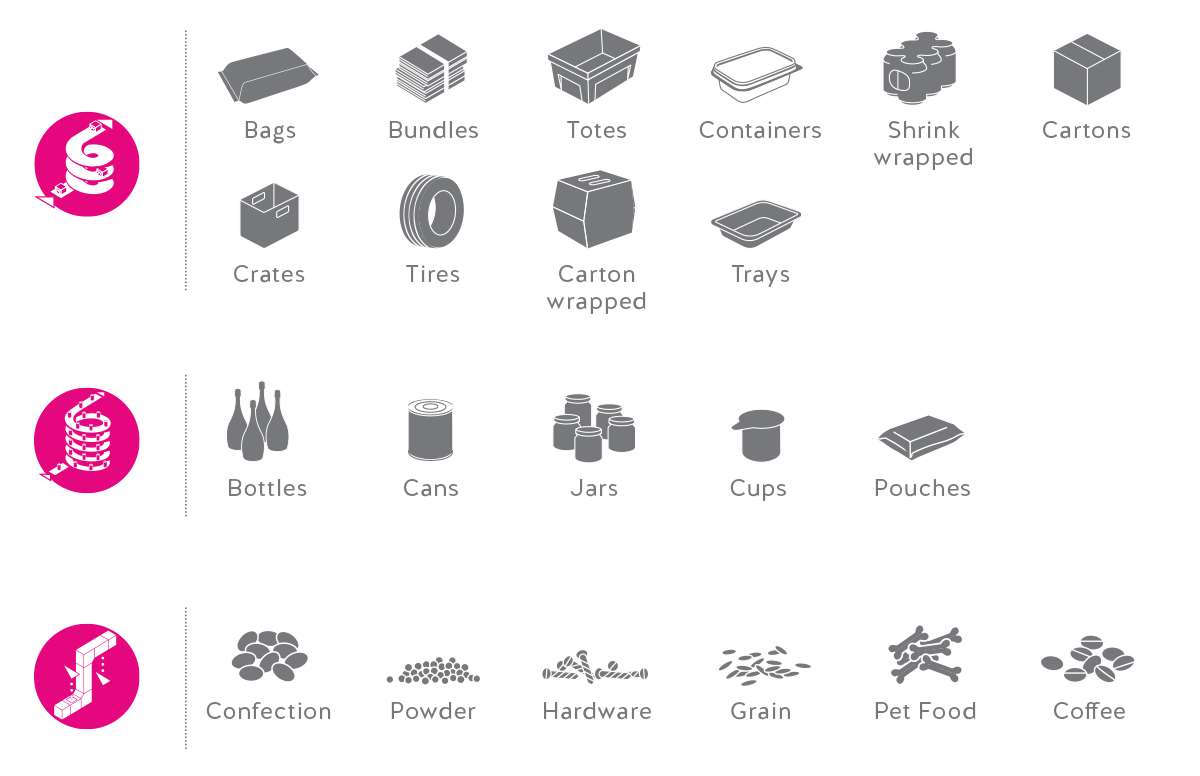

Ryson Product Diversity – On Display at Two Vastly Different Shows

This week, Ryson is exhibiting at two distinct trade shows: The MHEDA Convention (focused on warehousing and distribution) and also the International Powder & Bulk Solids Conference & Exhibition (centered around bulk material handling). At first glance, these events may seem worlds apart. But for Ryson, they both reflect something core to our identity: Versatility and Product Diversity.

Our Spiral Conveyors, Bucket Elevators, and other vertical conveying solutions are designed with adaptability in mind. Whether it’s helping an e-commerce fulfillment center streamline its picking process or moving powder and granular products through a food processing facility: Ryson’s modular and space-saving solutions can be tailored to fit.

Find us at these Shows:

-

MHEDA conference At MHEDA, we spoke to warehouse operators looking to improve floor space, throughput, and automation integration. MHEDA is the Material Handling Equipment Distributors Association. It is dedicated to serving all segments of the material handling business community including systems integrators, storage and handling and industrial truck distributors.

“From raw materials to packed boxes, Ryson supplies vertical conveyors that serve designers, warehouse teams, and maintenance managers. The MHEDA conference helped us get in touch with a lot of these supply chain and warehousing professionals to talk about our solutions. We had a great time!” (TK Haddadi, Ryson Sales Manager)

- At Powder & Bulk Solids, we’ll connect with manufacturers and processors handling powders, grains, and other bulk materials, where cleanliness, containment, and gentle handling are key. The Powder Show also connects bulk material handling and dry processing suppliers with manufacturing decision makers. The show features 350+ expert suppliers demonstrating powder manufacturing technology and solutions. They also have free educational sessions on pneumatic conveying, storage, feeding, and more. With a focus on innovative product solutions and quality control systems.

“I have noticed the biggest difference in this show is the amount of application engineers that want to know more. Additionally, it is an exciting opportunity to show off our high-quality products, but also to learn the needs of our potential customers.” (Bill Keane, Ryson Account Manager)

Our product line serves such a broad range of industries. From food and beverage to pharmaceuticals, packaging, reverse logistics, and more, we don’t believe in a one-size-fits-all approach. Instead, we show up where our customers are—and that means being present in multiple industries with different challenges but shared goals: efficiency, reliability, and smart use of space.

Our product line serves such a broad range of industries. From food and beverage to pharmaceuticals, packaging, reverse logistics, and more, we don’t believe in a one-size-fits-all approach. Instead, we show up where our customers are—and that means being present in multiple industries with different challenges but shared goals: efficiency, reliability, and smart use of space.

What It Means for Our Customers

For current and future partners, Ryson’s presence at both shows means you’re working with a company that understands your industry. And likely understands your customer’s industry, too. That cross-industry perspective helps us develop more informed, forward-thinking solutions.

Find out more at www.ryson.com.

Domestic Supply Chain Resilience with Ryson’s U.S.-Made Spiral Conveyors

When the “reciprocal tariff” went live on April 2, 2025, an imposed a baseline 10 percent duty on virtually every imported product became a reality – with even steeper rates for countries running the largest trade deficits with the United States. Two weeks later a federal court allowed the tariffs to remain in effect while legal challenges play out. It confirms that the new tax is already baked into purchase prices for overseas equipment. For material-handling managers shopping for spiral conveyors, that instantly raises the cost of any unit – or components shipped from abroad. A domestic supply chain clearly has an acute advantage.

Because Ryson manufactures every spiral conveyor in the USA, our customers avoid this surcharge entirely. Yet this tariff shield is only the first advantage. Choosing a U.S.-built machine also hard-wires domestic supply chain resilience into day-to-day operations.

Reliability That Pays Back Long After the Tariff Debate

Tariffs grab headlines, but life-cycle cost decides whether a conveyor’s cost of ownership. Ryson spirals use heavy-duty nickel-plated chain, sealed-for-life bearings and a single-motor drive.

Flexibity to React to Demands

The future of domestic business may evolve to account for potential supply chain and inventory constraints. That is where Ryson Spirals shine. Because of their modular design, they offer flexibility and the ability to be field modified if line or product flow are necessary in a facility. This is also particularly important to customers that are looking to adapt or update existing properties as cost saving measures, instead of new construction.

A Smaller Footprint—and a Lower Energy Bill—to Match Tight Warehouse Real Estate

Space in modern fulfillment centers can top $20 per square foot per year. A white paper Ryson shows that swapping incline belts for a spiral physically frees up to 30 percent of the floor area previously devoted to elevation changes, while the single-motor design trims energy use and wiring complexity. For e-commerce, packaging, food & beverage or any CPG line where every square foot matters, that real-estate dividend quickly dwarfs the headline purchase price.

Service and Spare Parts with Immediate Availability

Service and Spare Parts with Immediate Availability

Tariffs are only part of the risk of depending on overseas suppliers; shipping bottlenecks and geopolitical surprises can strand critical components offshore. Because Ryson stocks components in Virginia and typically ships replacements the same day they are ordered, downtime measured in hours never stretches into weeks. Factory-trained technicians can also be onsite quickly anywhere in the United States—no visitor visas, no trans-Pacific flights, just rapid support through a domestic supply chain that stays local.

Built-In Lead-Time Security

A U.S.-based production line means components, assembly and final testing all happen inside the country you operate in. Recent Ryson blog posts highlight projects where customers trimmed weeks off project schedules simply because the spiral could ship by truck instead of vessel or air cargo. One article describes how simplified RFQs and domestic fabrication “make the proposal and project-planning cycle faster” for integrators and end users (read more). Another, published just two months ago, shows how a modular spiral design eased a warehouse bottleneck on a tight deadline—something that would have been impossible if parts were still crossing the Pacific when the install window opened (read more). You can also watch our video that shows some of our many design advantages .

Domestic Supply Chain Bottom Line for 2025 Capital Budgets

Trump tariffs now add at least 10 percent to imported goods, and trade experts see no near-term path to repeal. Purchasing a Ryson spiral conveyor—engineered, built and supported in the United States—mitigates that cost exposure while delivering proven reliability, a minimal footprint and lower energy consumption. When your operation depends on uptime and quick project turnarounds, those advantages are worth far more than the tariff you avoid. It should be noted that while domestic spiral sales from Ryson will not be affected by tariffs, the price of a few raw materials may increase over time.

If you’re planning upgrades for warehousing, intralogistics, e-commerce fulfillment, packaging or food & beverage lines, contact Ryson for a tariff-proof quote—and feel the difference that domestic supply chain resilience makes from day one.