Spiral Conveyor Solutions and Customization (An In Depth Look)

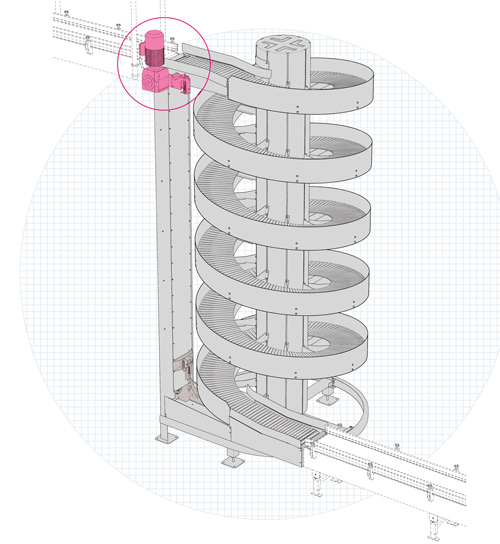

Every facility faces its own set of challenges. Whether it’s limited floor space, high throughput demands, or complex integration with other automation systems, no two operations are identical. That’s why flexibility is key when choosing vertical conveying equipment, and it’s where Ryson Spiral Conveyors stand out.

The Solution

Spirals are designed with a modular approach, which makes them easy to configure for specific layouts and requirements. Facilities can customize the infeed and discharge heights, direction of travel, and footprint so they align seamlessly with existing systems. As a result, this adaptability makes Spirals suitable not only for brand-new greenfield projects but also for tight brownfield environments, where space is often at a premium.

Modular Advantage

One of the key advantages of Ryson’s modular design is its flexibility for future changes. Because Ryson Spirals are built with a modular structure, they can be easily field modified to meet new layout or production requirements. Whether it’s changing the elevation, reversing the direction, or adapting the conveyor to serve a different line, the existing spiral can be repurposed on-site with minimal downtime. This adaptability allows companies to extend the life of their investment and significantly reduce costs—often achieving the functionality of a new spiral at just a fraction of the price.

Beyond their physical flexibility, Ryson offers a variety of Spiral models engineered for different applications.

Ryson Spiral Models at a Glance

-

Unit Load Spirals: Designed for cartons, totes, and trays with smooth and reliable transport.

-

Mass Flow Spirals: Handle bottles, cans, and other small items in continuous flow.

-

Multiple Entry/Exit Spirals: Allow products to enter and exit to or from several levels, saving even more space. They can support complex layouts and provide flexibility improving flow without adding more conveyors.

-

Dual Track Spirals: Two spirals in one frame, doubling capacity in the same footprint.

-

Narrow Track Spirals: Compact spirals for smaller loads, ideal in tight spaces or retail settings.

-

High Capacity Spirals: Handle larger loads and higher throughput with robust design.

This range of models ensures there’s a Spiral solution for nearly any industry or application, from e-commerce fulfillment to high-volume food and beverage production.

Spiral Customization Possibilities

Customization also extends to performance options. Customers can specify reversible operation, lane dividers for handling mixed products, and advanced drive technology that supports energy efficiency and long-term reliability. Each Spiral is built to deliver smooth, continuous transport. Therefore it minimizes product damage while maximizing throughput.

Customization also extends to performance options. Customers can specify reversible operation, lane dividers for handling mixed products, and advanced drive technology that supports energy efficiency and long-term reliability. Each Spiral is built to deliver smooth, continuous transport. Therefore it minimizes product damage while maximizing throughput.

Ultimately, Ryson Spiral Conveyors are not one-size-fits-all. But they’re engineered to match the precise needs of each operation. That combination of modular design and customization ensures lasting value for facilities under pressure to operate smarter and more efficiently.

You can find many examples of our application solutions on the Ryson YouTube Channel.

Avoid Downtime In Your Warehouse During The Busy Season

As the holiday season approaches, warehouses and distribution centers brace for their busiest months. Order volumes spike, shifts run longer, and every minute of uptime matters. When operations rely on high-performance equipment like Ryson Spiral Conveyors, preparation is key to ensuring a smooth and continuous operation.

As the holiday season approaches, warehouses and distribution centers brace for their busiest months. Order volumes spike, shifts run longer, and every minute of uptime matters. When operations rely on high-performance equipment like Ryson Spiral Conveyors, preparation is key to ensuring a smooth and continuous operation.

Why Preventive Planning Matters

During peak demand, even a brief unplanned stop can lead to costly ripple effects. A single stalled conveyor line can delay hundreds of shipments and reduce throughput. Most downtime issues can be prevented with foresight, and that starts with having the right spare parts on hand.

Ryson Spirals are built for reliability and long life. But like any mechanical system, wear parts such as bearings, chains, or slats may eventually need replacement. This can also happen if a jam happens. Waiting until a component fails can lead to avoidable production halts and overnight shipping costs. Having a stocked Spiral Conveyor spare parts kit helps your maintenance team react instantly and keep your lines running.

Get more information on the Ryson Spare Parts Kit and Preventative Maintenance.

Get more information on the Ryson Spare Parts Kit and Preventative Maintenance.

Avoid Downtime & Keep Operations Flowing

Avoid Downtime & Keep Operations Flowing

Facilities that plan ahead often maintain a small inventory of critical parts for each Spiral. These include drive chains, bearings, slats and transition rollers. Those are items that see the most use during heavy production cycles. With a complete spare parts kit, maintenance teams can perform quick repairs without waiting for deliveries or service calls.

Ryson’s modular design makes these parts easy to replace, further reducing downtime. Because every Spiral is built using standard components, facilities can swap out worn parts efficiently and get back to full operation faster.

Plan Now, Relax Later

A proactive maintenance approach pays off, especially when the holiday rush begins. Taking time now to review your Spirals’ condition and replenish your spare parts stock can mean the difference between an hour of maintenance and a day of downtime.

Contact Ryson today to learn more about recommended spare parts kits for your Spiral Conveyors. Our service team can help identify which components to keep in inventory. So your operations stay efficient and uninterrupted all season long.

Advantages of Modular Construction: A Ryson Case Study

Faster Repairs and Lower Costs: The Advantages of Modular Construction in Ryson Spirals

![]() Unexpected challenges can test both design and customer support. Recently, Ryson had the opportunity to demonstrate the strength of our Modular Design and the responsiveness of our team.

Unexpected challenges can test both design and customer support. Recently, Ryson had the opportunity to demonstrate the strength of our Modular Design and the responsiveness of our team.

A Spiral Conveyor shipped to our Integrator Partner, Conveyco Technologies, sustained structural damage during transit after a trucking accident. Instead of delays and costly replacement, Ryson’s Production Team immediately stepped in. We quickly manufactured replacement parts, taking full advantage of our modular construction. Because the entire Spiral did not need to be rebuilt, valuable time and money were saved.

Within just two weeks, the repaired Spiral was commissioned and running at Conveyco’s installation. The customer was impressed with the speed of the solution and the ease of the repair. This situation not only highlighted Ryson’s responsiveness but also showcased the practical advantages of our modular approach.

Ryson Spirals are engineered with field modification in mind. Whether adjusting to layout changes or replacing damaged sections, our conveyors can be adapted with minimal downtime. This adaptability keeps operations moving while avoiding the expense of building a completely new Spiral.

Ryson Spirals are engineered with field modification in mind. Whether adjusting to layout changes or replacing damaged sections, our conveyors can be adapted with minimal downtime. This adaptability keeps operations moving while avoiding the expense of building a completely new Spiral.

Additional Benefits of Modular Construction

The advantages of modular construction extend well beyond quick repairs. Ryson Spirals offer:

-

Flexibility in design: Modular components allow for tailored infeed and discharge heights, direction changes, and compact footprints.

-

Simplified maintenance: Individual sections can be replaced or upgraded without dismantling the entire Spiral.

-

Scalability: As operations grow, Spirals can be modified or expanded to support new production demands.

-

Reduced total cost of ownership: Lower repair costs, faster installation times, and long-lasting durability make modular systems more cost-effective.

Our sales manager TK Haddadi also commented:

“The modular design of our Spirals is a real game-changer. If a customer needs a last-minute layout tweak or wants to adapt their line months after installation, we can accommodate those changes quickly and efficiently. That flexibility adds a lot of value, both during the project phase and long after the system is up and running.”

In this case, our modular design minimized disruption and turned a potential setback into a successful installation. The result was a satisfied customer and proof of how Ryson delivers dependable solutions quickly and efficiently.

Ryson Wraps Up a Successful Pack Expo 2025 in Las Vegas

As Pack Expo 2025 in Las Vegas comes to a close, we reflect on another very successful show. This year’s Pack Expo brought together thousands of industry leaders, and our booth was a hub for meaningful conversations, live demonstrations, and valuable connections.

A Global Presence at the Booth

We were honored to welcome members of our Dutch parent company, the Royal Apollo Group. CEO Claudia van den Pol and VP of Sales & Marketing Peter van der Klooster joined us throughout the show. Their participation reinforced our strength as a global company and highlighted our commitment to serving customers worldwide.

Engaging with Visitors

Engaging with Visitors

Our Sales Team, led by Taoufik “TK” Haddadi, connected with countless visitors to discuss how Ryson equipment can improve efficiency and reduce costs in packaging and logistics operations. Marketing Manager Ken Rygh was also on hand to connect with our media partners and integrators for new opportunities.

Service Manager Jeffery Montgomery and Service Technician Ryan Rhoades provided direct insight into equipment service and maintenance. Many visitors appreciated the opportunity to ask specific questions and learn how Ryson supports long-term reliability in the field.

Live Equipment Demonstrations

The highlight of our booth was the opportunity to see Ryson machines in action. Visitors could have a look at our three flagship models:

-

Case Spiral Conveyor – moves cartons, totes, and cases vertically and can be handled smoothly in a compact footprint.

-

Mass Flow Spiral Conveyor – transports items like cans and bottles with continuous mass flow.

-

Bucket Elevator – an enclosed, gentle handling conveyor for bulk materials such as seeds and powders.

The demo machines at the booth gave attendees a clear picture of how Ryson’s vertical conveying solutions deliver performance and reliability while saving valuable floor space.

Looking Ahead

Pack Expo 2025 once again confirmed why it is such a vital event for the industry. We thank everyone who visited our booth and shared their time with us in Las Vegas. The conversations and connections made will continue to strengthen our partnerships long after the show. We look forward to continuing these discussions and working with customers and partners well beyond the exhibition floor.

Building Future-Proof Warehouses: Trends Shaping the Next 10 Years

Future proofing warehouses and distribution centers has become more important than ever. Online shopping keeps climbing, customers expect orders faster and with zero errors, and supply chains seem to hit a snag every other week. On top of that, space is expensive, finding and keeping workers is tough, and day-to-day costs are climbing.

Forward-looking operations are responding by blending robotics, advanced software, and strategic process design. This hybrid approach is shaping the warehouses of tomorrow, making them smarter, leaner, and more resilient.

The Pressures Driving Change

Rents for industrial space are at record highs, while labor costs have risen by more than a third in the past five years. Compounding the issue, 80% of warehouses still operate manually, leaving them exposed to labor shortages and high turnover. Worker injury rates also remain above average, adding further strain.

As a result, companies are prioritizing solutions that optimize every square foot, reduce reliance on scarce labor, and increase throughput without costly new construction.

Automation and Orchestration

Automation and Orchestration

Robotics are no longer a futuristic concept, they’re now widely deployed to handle picking, packing, and material transport. Implementation times have dropped from 18 months to less than half a year, making ROI faster and more accessible.

However, automation delivers its full potential only when supported by intelligent software. Warehouse Execution Systems (WES) are increasingly viewed as the “central nervous system” of modern facilities, coordinating robotics, conveyors, sortation, and manual work in real time. Cloud-based WES further enables scalability and future-proofing, eliminating the burden of on-site servers and improving resilience against disruptions.

Looking Ahead: The Future Proof DC

The warehouse of the future is hybrid: robotics performing repetitive work, software orchestrating complex decisions, and people focusing on value-added tasks. This model creates operations that scale easily, adapt quickly, and remain cost-effective even in volatile markets.

Future-proofing is less about chasing the latest trend and more about building adaptable systems that can evolve alongside business needs. Companies investing in flexible infrastructure today will be best positioned for tomorrow’s challenges.

Where Ryson Spirals Fit

Where Ryson Spirals Fit

Alongside robotics and software, space optimization remains central to warehouse efficiency. Ryson Spiral Conveyors provide a proven way to move unitized loads vertically while conserving valuable floor space. By integrating advanced drive technologies and modular designs, Ryson Spirals complement automation strategies and support sustainable, future-ready operations.

Learn more about Ryson.

Ryson Anniversary: 30 Years of Innovative Conveying Solutions

Ryson Anniversary: Three Decades Of Quality, Innovation, and Teamwork

Ryson Anniversary: Three Decades Of Quality, Innovation, and Teamwork

This year marks a milestone for Ryson as we celebrate 30 years of designing and manufacturing Spiral Conveyors and Bucket Elevators in the United States. Since our founding in 1995, Ryson has grown from a small manufacturer into a recognized leader in vertical conveying solutions across North America and beyond.

Over the decades, our commitment has remained steady: building high-quality, reliable machines while continuously improving efficiency, safety, and sustainability.

From Local Manufacturer to Global Leader

Ryson began in Yorktown, Virginia. We started with a new concept of vertical conveying in the US based on the design principles from our then sister company Royal Apollo Group from the Netherlands. The goal was offering smarter vertical conveying options to the American market. Today, we are part of the Royal Apollo Group. It gives us a global footprint with manufacturing in the Netherlands, USA, and Thailand. Also with service support in key regions including China, India, and Mexico.

This global reach ensures that our customers benefit from localized service while trusting in worldwide expertise.

Milestones Along the Way

Our 30-year journey has been shaped by innovation and customer collaboration:

-

Spiral Conveyors became our flagship product, known for saving floor space while improving throughput.

-

Bucket Elevators expanded our ability to handle bulk materials like powders, seeds, and grains.

-

Rotating Conveyors provided unique in-line orientation without reducing line speed.

More recently, we’ve embraced energy efficiency by integrating advanced IE5 motors into our Equipment. This further helps facilities lower costs and meet sustainability goals.

Built on Partnerships

Built on Partnerships

Ryson’s success would not be possible without our integrators, distributors, and loyal customers. Many of our relationships span decades, built on trust, support, and shared success. Just as important, our employees (many with long tenures) have carried forward a culture of quality and dedication that defines every Spiral leaving our facility.

Looking Ahead

As Ryson steps into its next chapter, our focus remains clear. Continue leading in vertical conveying while adapting to the needs of tomorrow’s supply chains. With e-com, food production, and logistics evolving quickly, Ryson equipment stands ready to support efficiency and growth for years to come.

Brownfield projects – or upgrading existing facilities – is becoming a growing trend, and the Ryson product line is uniquely qualified to help upgrade existing plants, and increase their efficiency while lowering their costs to operate. More and more Ryson equipment is being considered essential to “future-proofing” manufacturing and warehousing businesses.

We are proud to celebrate this 30-year anniversary and extend a heartfelt thank you to our partners, customers, and employees who made this journey possible.

We are proud to celebrate this 30-year anniversary and extend a heartfelt thank you to our partners, customers, and employees who made this journey possible.

Check out a Ryson Demo Spiral With Our Partners

At Ryson, we believe that seeing our spiral conveyors in action makes all the difference.

At Ryson, we believe that seeing our spiral conveyors in action makes all the difference.

That’s why we’re proud to collaborate with our outstanding integrator partners who showcase demo spirals in their facilities across North America.

These demo units give prospective customers the chance to witness firsthand the compact footprint, smooth product handling, and versatility that spiral conveyors bring to a wide variety of industries.

Having demo spirals strategically located around the country allows visitors, engineers, and operations teams to evaluate our solutions up close. It’s an invaluable way to experience how a Ryson Spiral can help maximize floor space and improve throughput in real-world applications.

Demo Spirals with Our Partners

-

NuMove – Montreal, QC, Canada

-

Element Logic (former ABCO) – Carlstadt, NJ

-

Conveyor Handling Company (CHC) – Elkridge, MD

-

Scott Automation – Charlotte, NC

-

Carolina Handling – Greenville, SC

-

Cisco Eagle – Dallas, TX

Spotlight: Conveyor Handling Company 50th Anniversary Celebration

Last week we attended the CHC 50th Anniversary open house. Their event was a gateway to the future of material handling. Ryson was able to show off our Spiral. The event was well received and many great conversations were had.

Spotlight: NuMove’s Center of Excellence

Spotlight: NuMove’s Center of Excellence

This week marks an exciting addition with the inauguration of NuMove’s Center of Excellence in Montreal. The new facility highlights advanced automation solutions and also features a Ryson Spiral Conveyor as part of the showcase. We are proud to see our spiral included in this innovative environment, where customers can see modern material handling technology integrated and operational.

Grateful for Trusted Partnerships

Our network of partners is instrumental in making Ryson spirals accessible to a broad range of industries and regions. By offering demo units in their showrooms and innovation centers, they help demonstrate the strengths of our products in a way that can’t be captured in brochures or videos alone.

As TK Haddadi, Ryson Sales Manager, put it:

“We are so grateful to our partners for featuring our Spirals in their facilities. It’s through these collaborations that more customers can truly understand the value of our equipment, and we’re proud to stand beside such innovative and forward-thinking organizations.”

See a Spiral Near You

If you’re interested in seeing a Ryson Spiral in action, we encourage you to connect with one of our integrator partners listed above. Their demo facilities are an excellent way to experience the technology. Moreover you can learn how it can fit into your particular operation.

Spiral Efficiency Redefined: Ryson Spirals with SEW DR2C IE5 Motors

Link to SEW Motor

In today’s competitive marketplace, companies are seeking every advantage to reduce costs and improve sustainability. At Ryson, we’ve taken Spiral Efficiency to the next level by optionally equipping our Spiral Conveyors with SEW’s new DR2C IE5 motors. This powerful combination directly supports lower operating costs while advancing sustainable operations.

In today’s competitive marketplace, companies are seeking every advantage to reduce costs and improve sustainability. At Ryson, we’ve taken Spiral Efficiency to the next level by optionally equipping our Spiral Conveyors with SEW’s new DR2C IE5 motors. This powerful combination directly supports lower operating costs while advancing sustainable operations.

The DR2C IE5 motor is engineered to cut energy losses by 50% compared to conventional motors. For operations that rely on frequent starts, stops, or variable loads—like e-commerce fulfillment centers, intralogistics, or food and beverage plants—this level of Spiral Efficiency translates into measurable savings on energy bills without reducing throughput.

Compact design also plays a role in efficiency. The motor’s interior permanent magnet technology delivers higher power density in a smaller footprint. For facilities already saving space with Ryson Spirals, this creates an even leaner installation. Combined with long service life and reduced maintenance needs, Spiral Efficiency becomes not only about energy but also about reliability and long-term savings.

Sustainability is another dimension of Spiral Efficiency. The IE5 motor requires half the amount of electrical steel and aluminum compared to older designs. This reduces both energy consumption and raw material demand—aligning your conveyors with ESG initiatives and corporate sustainability targets.

“Ryson’s strategic partnership with SEW has been a valuable asset. They are always willing to work with us to meet the rigorous demands of our production team. We are all excited to make their new line of motors available on our equipment.” Dave Wineman – President, Ryson International.

![]() Future-ready integration makes the DR2C IE5 motor even more attractive. It works seamlessly with SEW’s MOVI-C® modular system, ensuring conveyors remain flexible for changing production demands. With this motor, Spiral Efficiency is about more than energy—it’s about preparing your operation for tomorrow’s challenges. It can also reduce and simplify installation and integration, since the variable frequency drive is built into the motor. Find out more information at SEW.

Future-ready integration makes the DR2C IE5 motor even more attractive. It works seamlessly with SEW’s MOVI-C® modular system, ensuring conveyors remain flexible for changing production demands. With this motor, Spiral Efficiency is about more than energy—it’s about preparing your operation for tomorrow’s challenges. It can also reduce and simplify installation and integration, since the variable frequency drive is built into the motor. Find out more information at SEW.

Download more information on this motor here. We also welcome you discuss this new Spiral Efficiency firsthand at Pack Expo Las Vegas this month. Our team will be available to discuss how Ryson Spirals powered by SEW IE5 motors can cut costs and support your sustainability goals.

Ryson Product Line: Exploring Ryson’s Full Range of Conveying Solutions

The Diversity of the Ryson Product Line

The Ryson Product Line is recognized for its innovative Spiral Conveyors, but it includes much more. Over the years, Ryson has expanded its offerings to meet diverse material handling needs across many industries. Each solution is engineered for reliability, efficiency, and long-term performance.

Spiral Conveyors

Spiral Conveyors

The Ryson Product Line is best known for Spiral Conveyors. Available in models for unitized loads and mass flow applications. They save valuable floor space while increasing throughput. Their proven reliability has made them a trusted choice for integrators and manufacturers worldwide.

Ryson Spiral Models include:

-

Unit Load Spirals – designed for cartons, totes, and other unitized loads.

-

Mass Flow Spirals – ideal for handling bottles, cans, and jars in bulk.

- Narrow Trak Spirals – Handle smaller items – either single file or in a mass flow.

All models are modular and customizable, with options for reversible operation, multiple infeed or discharge points, and can also be delivered stainless steel construction for wet environments. Spirals deliver low maintenance, long life, and reliable uptime, making them a trusted solution in distribution, packaging, and food processing.

For more details, download the Ryson Spiral Conveyor brochure on our website.

Bucket Elevators

Bucket Elevators

The Ryson Product Line also includes configurable Bucket Elevators. Unlike conventional designs, Ryson Bucket Elevators are fully enclosed, protecting materials from dust and contamination while keeping the plant environment clean. They efficiently handle powders, pellets, seeds, and other bulk materials with minimal spillage.

Our Bucket Elevators are modular and can be configured to fit tight layouts, with gentle product handling that reduces waste. This makes them ideal for industries like food, chemicals, and construction.

You can also download the Ryson Bucket Elevator brochure to learn more about features and configurations.

Rotating Conveyors

Rotating Conveyors

Another important part of the Ryson Product Line is the Rotator. This inline conveyor rotates products 90 or 180 degrees without slowing throughput or requiring extra equipment. It ensures cartons or packages are properly oriented for labeling, scanning, or case packing.

Additionally, by maintaining a continuous flow, the Rotator eliminates unnecessary handling steps and boosts efficiency in packaging and distribution operations.

For specifications and applications, download the Ryson Rotator brochure.

Taken together, these products illustrate how Ryson offers more than just Spirals. We provide a wide array of conveying solutions—each engineered to optimize space, reduce maintenance, and keep production lines running smoothly. From packaged goods to bulk materials, our equipment delivers performance across diverse applications.

Finally, Ryson is proud to serve many industries with a broad range of solutions. Whether you need a Spiral Conveyor, a configurable Bucket Elevator, or an inline Rotator, Ryson provides equipment designed with innovation, quality, and long-term reliability in mind. Our diversity means one thing for our customers: the right solution for nearly any material handling challenge.