2025 Happy Holidays from the Ryson Team

Wishing you and your team a joyful holiday season and a successful, inspiring year 2026 ahead !

As 2025 comes to an end, we want to take a moment to say thank you to our partners and customers. Thank you for your support, partnership and!

We’re looking forward to more great projects together in 2026.

This week, the Ryson team had the pleasure of welcoming Claudia van den Pol (CEO of the Royal Apollo Group our parent company) to our Ryson office in VA. During her visit Claudia took the opportunity to connect with the team during the work hours but also with a speech at the Christmas party. She also shared some thoughtful holiday gifts and initiated meetings to finalize important business initiatives for the upcoming year.

This week, the Ryson team had the pleasure of welcoming Claudia van den Pol (CEO of the Royal Apollo Group our parent company) to our Ryson office in VA. During her visit Claudia took the opportunity to connect with the team during the work hours but also with a speech at the Christmas party. She also shared some thoughtful holiday gifts and initiated meetings to finalize important business initiatives for the upcoming year.

Her visit reinforced the strong collaboration between Ryson and our parent company setting a positive tone for 2026. In a recent LinkedIn update Claudia writes:

“Being back with the Ryson team reminded me why the US feels like a true second home to me. Every visit leaves me energized and deeply grateful for the people who carry our mission forward every day.”

We’re grateful for a successful and productive year at Ryson!

This success wouldn’t be possible without our dedicated team, our valued customers, and the continued support from the Royal Apollo Group.

From all of us at Ryson, we wish you a joyful holiday season and a successful start to the new year.

Custom manufactured spirals down to RAL color choices.

Color Choices for Spiral Conveyors

At Ryson we offer our customers any of over (200) RAL color choices for their machine, at no additional cost.

At Ryson we offer our customers any of over (200) RAL color choices for their machine, at no additional cost.

This allows our integrators to match their adjoining conveyor’s color or be a little more creative with a brand matching color, which is sure to catch the eye of every visitor that enters the plant.

Customers may also choose a bright color for safety considerations.

These pink spirals are for a consumer brand in the beverage industry. Our Integration Partner, IPM specified this color on behalf of their customer. We couldn’t be more thrilled, since it’s so close to Ryson’s brand color.

Matching A Company’s Brand

An example for a corporate Identity matching spiral is this one in a big European warehouse for a famous meal kit delivery service. This was a job done through our parent company Royal Apollo Group.

Another job with an eye catching color were these bright yellow spirals. They were from a project with our Integrator Partner, Storcan Conveyor Systems & Automation for an operation of baked goods for a large Institutional Bakery in Ontario.

Equipment color plays a more important role than many realize. In many facilities, companies choose colors that match existing machinery to maintain a clean, consistent look across the production floor. Others select colors that reflect brand standards, reinforcing identity throughout the operation. In some cases, bright or high-visibility colors take priority to improve safety and make equipment easier to spot in busy environments.

Whatever the case, color remains a practical and intentional choice. Ryson understands these needs and offers flexibility to meet them. From neutral industrial tones to bold brand colors or high-visibility finishes, Ryson can supply Spiral Conveyors in the color that fits your facility, your standards, and your goals.

Ryson Spiral Conveyors are available in stainless steel and wet-environment versions as well. For more information on our vertical conveying solutions, visit our youtube channel, or visit www.ryson.com.

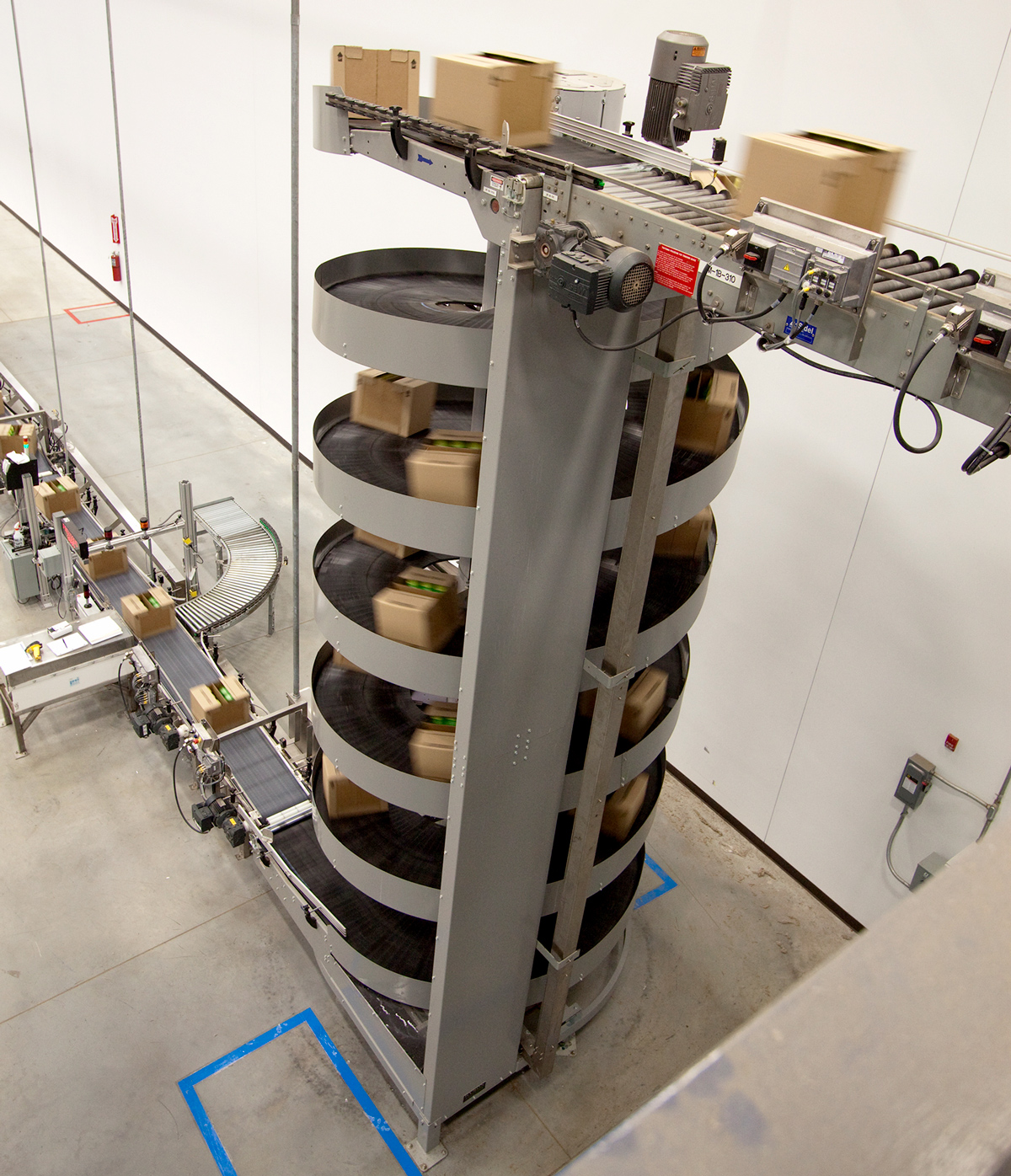

Future-Proofing Your E-commerce and Last-Mile Operations with Spiral Conveyors

The e-commerce boom is here to stay. Customers want their orders faster, and distribution centers are racing to keep up. Especially during peak consumption time like the holiday season.

If your facility is handling everything from clothing to electronics and struggling to meet tighter shipping windows, it’s time to explore new ways to stay ahead of the demand curve.

Why Spiral Conveyors are the best tool to optimize your warehouse or DC

Spiral conveyors have emerged as a vital tool for e-commerce and last-mile logistics because they increase efficiency without requiring a massive expansion.

By elevating packages and parcels, spiral conveyors free up floor space for picking, packing, and staging areas, all of which have become critical points of speed in today’s fulfillment process.

Modularity = Flexibility

What sets a modular spiral conveyor apart is its adaptability. In an industry that changes overnight—think holiday rushes, viral product fads, or sudden supply chain shifts—you need systems that can pivot quickly. Modular conveyors can be reconfigured to meet fluctuating throughput, whether you need more volume handling during peak season or a different angle to integrate with a new set of robotic picking arms.

Additionally, by integrating spiral conveyors with scanners, sortation equipment, and data-tracking software, you create a more cohesive, intelligent workflow. Packages flow upward or downward smoothly, and any operational insights—like throughput data or potential chokepoints—are easier to monitor. Over the long run, this synergy helps you respond to market changes without massive downtime or major facility overhauls.

Examples Of Ryson Spirals in DCs Around The World:

Food Distributor in Indianapolis:

Global meal-kit delivery Company:

Global Retail Distribution Center:

Staying competitive in e-commerce and last-mile delivery means finding agile solutions that can evolve with consumer trends. Spiral conveyors deliver that agility by minimizing space demands and simplifying vertical transport. If you’re ready to enhance your fulfillment process, connect with Ryson to see how a modular spiral conveyor can keep your operations running at top speed.

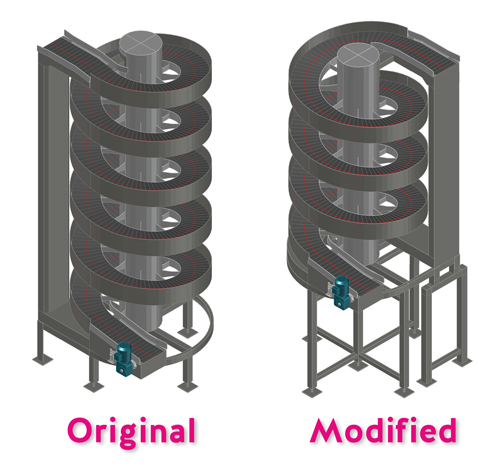

Production Floor Equipment Upgrades – Reconfiguring a Ryson Spiral

The Smart Advantage of Reconfiguring a Ryson Spiral

Production floors keep evolving, and many facilities now pursue Production Floor Equipment Upgrades to stay competitive. As layouts shift and automation expands, existing conveying equipment often needs to adapt. Fortunately, a Ryson Spiral already offers a built-in advantage: its modular design supports efficient and cost-effective reconfiguration.

When facilities upgrade machinery, add new automation, or reduce their operational footprint, space becomes a priority. A Spiral that once fed a certain line may now need a new discharge height, direction change, or extended elevation. Instead of replacing the entire unit, a reconfiguration allows teams to repurpose their existing investment. This approach keeps projects smart, fast, and budget friendly.

The Ryson design makes this possible. Every Spiral consists of modular components that technicians can add, remove, or re-space without rebuilding the framework. Because of this, most reconfiguring jobs happen on-site with limited interruption to production. In many cases, crews can complete the work in a single visit. The cost benefit is clear. A reconfigured Spiral operates like new at a fraction of the price of buying one.

“We recently supported a customer who needed more accumulation between their Spiral discharge point and a floor-level case packer. Their existing 1500-400 Spiral Conveyor declined empty cases from an automatic case erector on a mezzanine, but the line update required extra conveyor length to accommodate the additional accumulation demand. Our team proposed a revised design that lifted the discharge to a higher elevation and added a conveyor loop after the Spiral to create the needed distance. The reconfiguration also included an extended leg base platform, allowing the new conveyor path to pass cleanly under the Spiral on its way to the packer.”

– Steve Dillaman, Key Account Manager

Reconfiguration also supports broader operational goals. As companies adopt new automation, they often rethink product flow. A Spiral that once sat deep in a line may gain new value when redeployed toward storage, palletizing, or packaging. By adjusting the unit rather than replacing it, facilities maintain uptime and reduce waste.

When companies try to free up floor space, the impact grows even more. Reconfiguring a Spiral can help consolidate equipment, open aisles, and increase storage or production capacity. This approach creates a more flexible layout while keeping capital spending under control.

Every reconfiguration also receives the attention of the Ryson service team. They assess the unit’s condition, plan the mechanical changes, and confirm that the Spiral meets the revised application needs. The result is dependable performance that aligns with your updated operation.

As production environments change, a Ryson Spiral remains adaptable. Its modular structure turns Production Floor Equipment Upgrades into a practical opportunity rather than a major expense. Reconfiguring maximizes your original investment and lets your facility grow with confidence.

Ryson Wishes you a Happy Thanksgiving!

Ryson Thanksgiving Message

Ryson Thanksgiving Message

Going into the holiday season, we pause, reflect, and express our gratitude. Each year reminds us how fortunate we are to work with partners who value reliability, innovation, and true collaboration.

We want to take a moment to share our sincere appreciation for your confidence and loyalty. Your trust fuels our commitment to build high-quality Spiral Conveyors and Bucket Elevators that support your operations year after year. Our employees take deep pride in every machine we hand-craft, and your continued support pushes us to keep improving and expanding into new applications we never predicted.

This season, we count our blessings for the growth of our company and the progress of our team. Yet most of all, we are thankful for you—our customers, integrators, partners, and suppliers. Your feedback, challenges, and encouragement motivate us to reach new levels of quality and service.

From all of us at Ryson, we wish you a happy, healthy, and memorable Thanksgiving. May the holiday bring you rest, warmth, and a long list of things to be thankful for.

– The Spiral Team

How 2026 Is Transforming Industry Priorities: Trends, Strategy, and Leadership

How 2026 Is Transforming Industry Priorities: Trends, Strategy, and Leadership

As 2026 is approaching, many companies plan for another year marked by rising costs and tight labor markets. These conditions shape how executives invest, modernize, and set priorities. Insights from the Ryson 2026 Outlook highlight the forces reshaping industry strategy and show how companies prepare for the year ahead.

Economic Shifts Influence Smarter Investments

Economic Shifts Influence Smarter Investments

Industry analysts expect an uncertain economic climate in 2026. Companies respond by focusing on equipment that keeps operations efficient and dependable.

Many facilities upgrade outdated machinery to cut downtime and reduce cost of ownership. Ryson Spiral Conveyors help meet these goals with reliable performance and thoughtful design that adapts as workflows change. They also help companies conserve floor space, which matters more as real estate expenses climb.

Leadership That Strengthens the Industry

A significant development for 2026 is the election of Claudia Van den Pol, CEO of the Royal Apollo Group, to the PMMI Board of Directors. Her international experience brings new perspective to PMMI and its members. She understands how global trends shape decisions across markets and her presence on the board supports broader collaboration and forward-focused planning for the packaging and processing community.

“I’m always inspired after attending PMMI events. This organization is truly amazing. It offers incredible opportunities to network, reconnect with familiar faces, and meet new ones, all while discussing the challenges and innovations shaping our industry. I am very proud and honored to have been elected to join the PMMI Board of Directors ” – Claudia writes on her LinkedIn

Automation Accelerates as Labor Stays Tight

Labor shortages continue across manufacturing, warehousing, and fulfillment. Leaders now view automation as essential. They want systems that run consistently and limit reliance on hard-to-hire skill sets. Spirals support this shift with smooth vertical transport, low maintenance, and compatibility with modern automated systems. Operations now expect equipment to work across multiple load types, layouts, and speeds without complex adjustments, something Spirals handle with ease.

Growing Sectors Shape Facility Design

E-commerce, direct-to-consumer distribution, and cold storage remain high-growth areas entering 2026. These operations demand fast throughput, flexible layouts, and dependable uptime. Spirals deliver these advantages while handling mixed load sizes and supporting multi-level infeed and outfeed configurations. This helps companies build compact footprints during a year when every square foot matters. In cold storage, Spirals continue to work reliably in sub-freezing conditions while helping customers maximize valuable refrigerated space.

Looking Ahead

The year ahead encourages leaders to adopt strategies that improve efficiency, reduce risk, and support long-term growth. Companies that invest in reliable automation and flexible layouts will stay competitive in a market that continues to change quickly. Ryson remains dedicated to these priorities with Spirals that deliver consistent performance and leadership that reflects a global view of industry needs.

Spiral Conveyor Maintenance: How the Ryson Service Team Delivers Reliability

![]() Reliable equipment starts with reliable support. At Ryson, our Service Team is dedicated to keeping your Spiral Conveyors running at their best. From installation to preventive maintenance, we help ensure smooth operation and long service life for every machine.

Reliable equipment starts with reliable support. At Ryson, our Service Team is dedicated to keeping your Spiral Conveyors running at their best. From installation to preventive maintenance, we help ensure smooth operation and long service life for every machine.

Our technicians can assist during installation to make sure each Spiral Conveyor or Bucket Elevator is set up correctly. A proper start-up helps avoid issues later and sets the foundation for reliable performance. Ryson’s experts can also train your team on Spiral Conveyor Maintenance best practices. With this training, your staff learns how to identify wear, perform routine checks, and prevent costly downtime.

One example for our fast and reliable service is this story from our Service Manager Jeff Montgomery:

“A customer’s Spiral Conveyor had come off its track, and slat sections were damaged. Even though it was purchased through a third party, we treated it like any other Ryson machine. I asked for the serial number, photos, and quickly sent a quote for one of our Virginia-based technicians to visit their Chicago facility.

Once I saw how urgent the issue was, I sent them chain-shortening instructions and training videos to help get things under control fast. We discovered the chain had never been shortened, which had caused the crash.

Our tech fixed the Spiral, trained their staff, and got them running again the same day. The customer was grateful for our quick response and ordered a spare parts kit afterward. This was a great example of teamwork between our different departments ensuring our customer gets fast solutions.”

Spiral Audit:

Spiral Audit:

To give customers a clear view of equipment health, Ryson offers machine audit services. During an audit, our technicians perform a complete inspection of your Spiral Conveyor. The audit report includes an evaluation of performance, parts condition, and recommendations for preventive or predictive maintenance. It also lists critical spare parts to keep on hand—because having the right parts nearby can make the difference between minutes and days of lost production.

Spare Parts Availability:

At our Yorktown, Virginia facility, Ryson keeps a full inventory of spare parts ready to ship. When an order comes in, we process it quickly to minimize downtime. This commitment ensures our customers always have access to the parts they need, exactly when they need them.

Of course, even with strong maintenance programs, unexpected issues can occur. That’s why the Ryson Service Team remains on call for rapid response. Whether it’s remote troubleshooting or an onsite visit, our technicians act fast to restore production and keep your lines moving.

With Ryson, you get more than world-class conveying equipment—you gain a trusted partner dedicated to performance, reliability, and long-term support. Visit our Parts & Service Page to find out more.

Vertical Conveying in Micro-Fulfillment Centers: What to Avoid

Rapid order fulfillment is now a baseline expectation in any industry. How you use every cubic inch can determine whether your operation thrives or backlogs. This is where smart design, seamless automation integration, and smart floor planning become critical.

Rapid order fulfillment is now a baseline expectation in any industry. How you use every cubic inch can determine whether your operation thrives or backlogs. This is where smart design, seamless automation integration, and smart floor planning become critical.

Let’s break down the common pitfalls and explore the key design strategies used by the most efficient MFCs operating under tight space constraints.

Common Design Mistakes That Kill Throughput

Even with the latest tech and good intentions, some MFCs fall into predictable traps:

Ignoring Vertical Space.

If you’re not leveraging vertical conveyors or spirals, you’re essentially giving away free real estate. Vertical spirals can quadruple your throughput density without expanding your footprint.

Other Design Mistakes can be the following:

- Overcomplicating Layouts:

Maze-like conveyor paths slow down order flow and confuse automated systems. Simplicity is speed. - Neglecting SKU Velocity:

Placing slow-moving SKUs in prime pick zones just because they fit conveniently? It’s time to re-slot and let fast movers take the spotlight. - Poor Integration With Automation:

When conveyors don’t interface smoothly with robots or AS/RS systems, you’re not scaling, you’re jamming the system with avoidable inefficiencies.

How Spiral Conveyors Help in Micro-Fulfillment Centers

How Spiral Conveyors Help in Micro-Fulfillment Centers

Spiral conveyors are ideal for micro-fulfillment centers (MFCs) due to their efficient use of vertical space, helping maximize limited floor area in urban settings.

They provide smooth, continuous transport between facility levels, reducing bottlenecks and speeding up order processing compared to lifts or elevators.

Ryson’s Spirals offer a modular design, which supports a variety of products and easy integration with automated systems. Their simple, reliable mechanics also lower maintenance needs and downtime risks. Overall, spiral conveyors enhance throughput, save space, and ensure reliable vertical conveying in compact MFC operations.

The Optimization Exercise: Designing a 100 sq ft Vertical Space

Let’s put it into practice. You’ve got 100 square feet to work with. Here’s how to squeeze out every ounce of efficiency:

Use Vertical Spirals in Corners. Corners are often dead zones, perfect for a vertical spiral conveyor that gains height without hogging floor space. Implement high-density shelving that evolves with your SKU mix. Think modular racks that can quickly accommodate seasonal shifts. Shorten travel time by designing a layout with minimal motion: inbound > pick > pack > outbound, all in a straight shot. Your spiral conveyor should also “talk” to your robotic arms or AS/RS for real-time handoffs: no manual intervention required. Use mobile carts or dynamic staging zones to absorb peak-period pressure without sacrificing core flow.

Best Practices Checklist for Micro Fulfillment Centers

- Use vertical conveyors or spirals to elevate product efficiently.

- Design short, direct conveyor paths that eliminate waste.

- Slot fast-moving SKUs in the most accessible areas.

- Pre-plan for automation, even if you’re not there yet.

- Build in flexibility so you can pivot with SKU/volume changes.

The Result: A Compact, Scalable Fulfillment Powerhouse

What’s the ROI of smart spatial planning? A compact, high-throughput MFC that delivers on speed, adapts as your business grows, and punches way above its square-footage weight. Whether you’re outfitting a dark store, urban fulfillment hub, or last-mile delivery zone, these principles help you turn constraints into competitive advantage.

In the era of quick commerce and just-in-time expectations, the question for logistics pros isn’t “can you deliver?”, it’s “how efficiently?”

Want to explore spiral conveyor solutions optimized for minimal footprints? Contact us to learn how leading fulfillment centers are rethinking vertical movement.

How Spiral Conveyors Ensure Product Integrity

In industries like food and beverage, safety product integrity and efficiency go hand in hand. Products must move quickly to meet demand, but they must also arrive pristine and damage-free. Spiral Conveyors provide a reliable way to meet both goals.

How Ryson Spirals Ensure Product Integrity

How Ryson Spirals Ensure Product Integrity

Traditional vertical transport methods often rely on lifts or manual handling, which can be inconsistent and introduce risk. Spirals on the other hand, use a chain slat design that gently and securely carries products at a constant rate. This reduces tipping, jamming, or damage, even when handling fragile items like glass bottles or open containers. Our Spirals are designed to transport products with consistent orientation, which may be critical in some operations. Ryson Spiral slats can also be equipped with friction inserts to help prevent items from slipping down in the incline.

Mass Flow Applications

In mass flow applications, Spirals excel at moving hundreds of bottles or jars in a single stream. By keeping products upright and evenly spaced, they ensure smooth movement to downstream equipment like fillers, cappers, or case packers. For packaged goods, unit load Spirals provide consistent transfer between levels, reducing unnecessary handling that can compromise safety.

The Right Integration

We always work closely together with our integrator partners to make sure the Spiral is being integrated properly into the existing line. Proper integration includes matching the speed and height transitions of the spiral with the overall conveyor system, adjusting side guides, chain tension, proximity sensors, and variable frequency drives (VFD) to ensure smooth product flow and reliable operation. Ryson offers a variety of end-to-end transition options to maximize a smooth transfer on and off the spiral. We also provide detailed manuals and checklists as part of our installation and integration process to ensure longevity and optimal performance.

Safety of Spiral Conveyors

Worker safety is also a major benefit. Spirals reduce the need for manual lifting, climbing, or repetitive handling tasks. This not only minimizes the risk of injury but also helps facilities cope with ongoing labor shortages. In highly regulated industries, Spirals help maintain compliance by supporting clean, controlled transport that aligns with food safety standards.

By combining efficient design with product and worker protection, Spiral Conveyors create safer operations while maintaining the throughput and efficiency modern facilities require. For manufacturers and distributors under pressure to deliver quickly without compromising quality, they are a dependable solution.

Find out more information about our full line of Vertical Conveying Solutions on the Ryson YouTube channel.