There are many factors that go into finding the ideal size and model for your Spiral application.

Ryson’s Spiral Conveyors are used in diverse applications across many industries. We offer many different models that allow us to vertically convey a large number of product types. But what is the ideal Spiral model for your needs? To find the best Spiral Application, first we need to know the dimensions of the largest product that will be conveyed. The slat width will have to be larger than that.

Ryson’s Spiral Conveyors are used in diverse applications across many industries. We offer many different models that allow us to vertically convey a large number of product types. But what is the ideal Spiral model for your needs? To find the best Spiral Application, first we need to know the dimensions of the largest product that will be conveyed. The slat width will have to be larger than that.

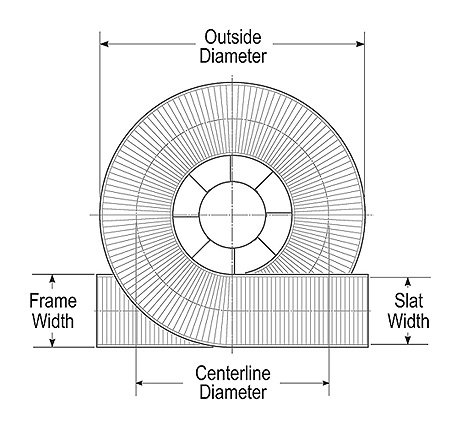

The outside diameter of a Spiral Conveyor is in part a function of the length of the slat (conveying surface) of that model. If you are looking to minimize floorspace, you could for example configure your product to run narrow side leading. That alone could reduce your conveying surface, thereby reducing your overall footprint.

The outside diameter of a Spiral Conveyor is in part a function of the length of the slat (conveying surface) of that model. If you are looking to minimize floorspace, you could for example configure your product to run narrow side leading. That alone could reduce your conveying surface, thereby reducing your overall footprint.

We offer spiral models with 6, 9, 12, 16, 20, 24, 30, and 36 inch wide slats. Consequently this allows transport of most any kind of conveyable items, from small to large. Download our model chart to find out most common dimensions.

Product Stability is also a consideration. A very sable product, like a tote for example, can have a very steep angle of incline. A can or bottle however, will need a very shallow angle of incline. Sometimes to accommodate tricky products the diameter will need to be expanded to keep the angle of incline low.

Ryson also has three basic styles of slats.

-

Inventory of different Ryson slat styles Case Slat Design – The first is designed to handle cases, and features overlapping slats that can be furnished with friction inserts to help prevent items from slipping down in the incline.

- Nesting Slat Design – This design features interlocking slats that have a smooth surface. This is used for Mass Flow operations. For example, when products such as cans or jars need to be side transferred on and off the spiral. The Spiral slats run flush along the feeding conveyor and create a smooth and seamless transition point.

- Induction Slat Design – This design creates a smooth conveying surface to facilitate product transferring to and from our spiral via our Induction and Divert Conveyors. They can also be furnished with a rounded friction insert that allow products to slide onto it, but helps keep them in place while on the spiral.

The diverse Ryson Product line can handle a wide variety of products with different, weights, sized and stability. Our experienced sales team can help you decide on a model that is ideally suited for your application. You can also view our own YouTube Channel to see some of our Spiral application videos.