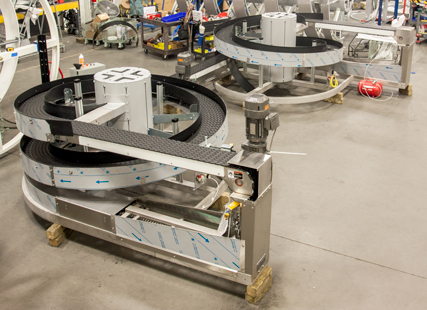

This week, we are shipping two of the shortest Mass Flow Spiral Conveyors we have manufactured. They will be used in an up-over-down configuration to clear an existing line.

This week, we are shipping two of the shortest Mass Flow Spiral Conveyors we have manufactured. They will be used in an up-over-down configuration to clear an existing line.

The customer needed to install a new bottling line in a tight space without interfering with an existing line. Their new layout will use one spiral to elevate bottles, in mass, over the existing floor-mounted conveyors and the other will bring them back down to the floor level.

All Ryson Spirals are made to order and these spirals are a perfect example of how the Ryson modular design is flexible enough to easily work with the most challenging of layouts.

These 1900-260 model spirals utilize our 10” wide mass flow slat to handle full PET bottles (10 to 64 oz.) at speeds of up to 650 bottles/minute. The Hybrid stainless steel construction allows these to be used in a wet environment.

For more information on the Ryson Mass Flow Spiral Conveyors, visit www.ryson.com, download the Mass Flow Spiral Brochure, or you can read application stories from our weekly blog.