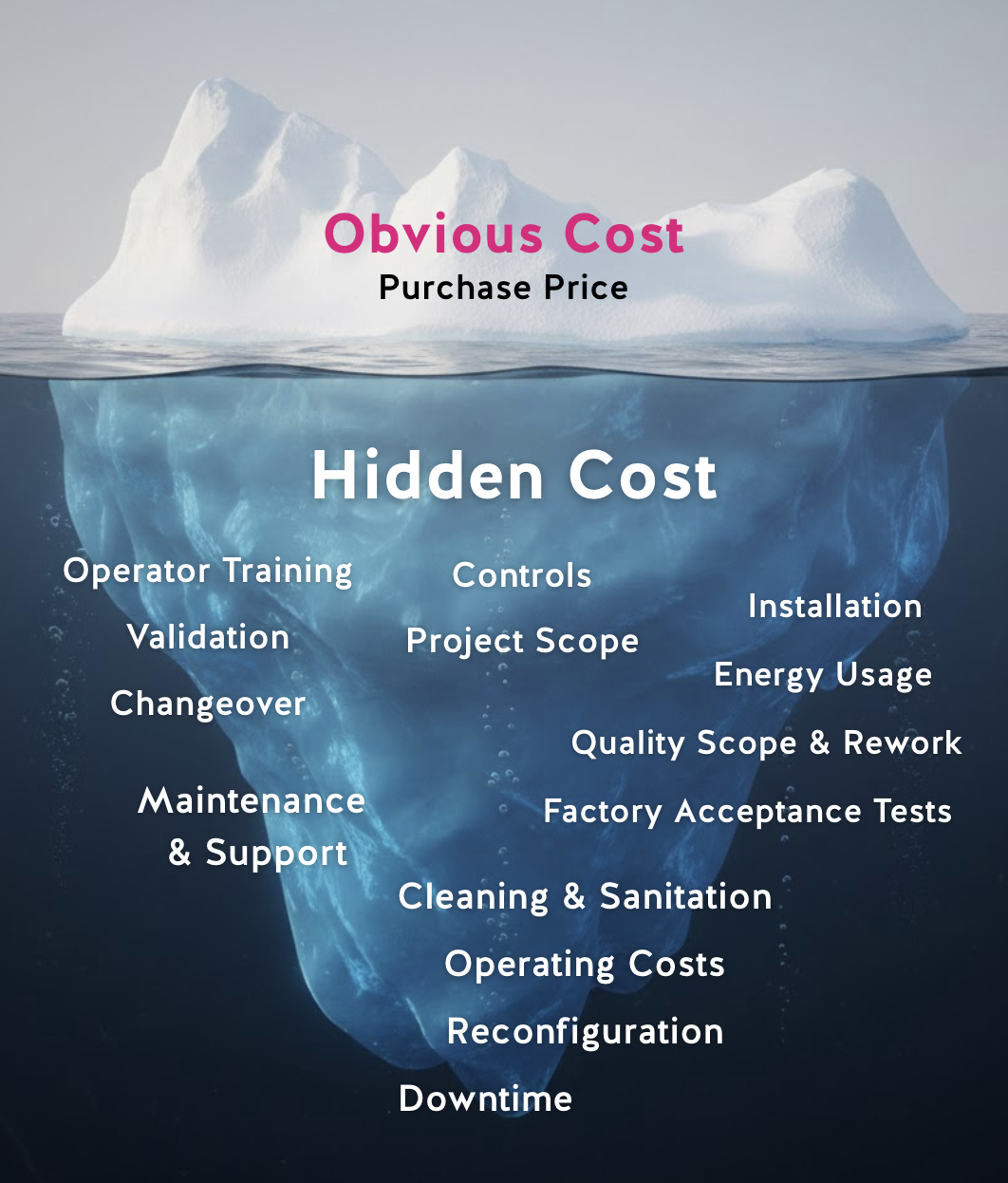

When businesses invest in industrial equipment, it’s easy to get tunnel vision. We often focus on the “sticker price”, number at the bottom of the quote. Oftentimes forgetting that an industrial asset is a decades-long relationship, not a one-time transaction.

This is the core of Total Cost of Ownership (TCO).

This is the core of Total Cost of Ownership (TCO).

In an industrial setting, focusing solely on the initial capital expenditure (CAPEX) is like looking at the tip of an iceberg while ignoring the massive, submerged mass that can sink your operational budget. A truly successful investment isn’t just about what you pay today; it’s about what you keep paying over the next ten to twenty years.

The True Cost of Industrial Assets

Understanding TCO requires looking at the full lifecycle of a machine. Generally, these costs fall into two distinct categories:

-

Acquisition Costs: This is the visible “tip.” It includes the purchase price, of course, but also the logistical hurdles like shipping, customs duties, and the complex process of installation and setup.

-

The “Hidden” Long-Tail Costs: This is where the budget often bleeds. It encompasses:

-

Operating Costs: The daily “rent” you pay to run the machine, from energy consumption and fuel to the personnel costs required for operation.

-

Training Costs: The specialized expenses for getting your workforce up to speed on new technology.

-

Maintenance & Support: The inevitable need for spare parts, routine servicing, and expert technical support.

-

Downtime and Poor Quality Costs: Perhaps the most painful of all. The lost productivity during maintenance or the financial drain caused by inefficiencies, breakdowns, and sub-par output.

-

What’s an example for TCO comparison?

As an example we can look at two vehicles, one with a low purchase price but that gets poor fuel mileage and requires frequent costly maintenance vs. another that has a higher purchase price but that gets good mileage and requires infrequent maintenance with reasonably priced components. Obviously the first will require less initial investment but with time it will cost more to “own” especially if used frequently and for long distances. If you include other less tangible costs like loss of use, or substitution costs, when the resource is unavailable because of repair and incidental costs like towing when the vehicle unexpectedly breaks down, the total cost of the initially less expensive option becomes rapidly more expensive to own than the other option.

TCO in Vertical Conveyance: The Ryson Spiral

When we apply this lens to vertical conveyance, the Ryson Spiral stands out as a prime example of why TCO matters more than the initial quote.

Ryson’s spirals are designed and manufactured to provide a lower total cost of ownership (TCO) when considering all costs associated with owning and operating equipment for vertical transportation of goods; initial price, shipping, installation, operation, maintenance, consumables, and reconfiguration.

Let’s break it down…

How Do Ryson Spirals Lower Your Cost of Ownership?

When evaluating total cost of ownership, vertical conveying becomes a long-term business decision, not a simple purchase. This is where the Ryson Spiral clearly stands apart.

Space efficiency

Space savings delivers an immediate return. A Ryson Spiral can reduce floor space requirements by up to 75 percent compared to traditional incline conveyors. That reclaimed space can delay building expansions or free room for new production lines. In facilities where floor space can cost more than $100 per square foot, those savings add up quickly.

Energy efficiency

Low energy consumption further reduces lifetime operating costs. Ryson Spirals use a low-friction conveying surface that moves product vertically with just one low horsepower motor. Traditional incline systems often require multiple conveyors and drives to achieve the same elevation change. In facilities operating dozens, or even hundreds, of conveyors, reducing the total number of motors can significantly lower annual energy use. Those savings appear directly on utility bills while also reducing heat and electrical load across the facility.

Durability

Durability also plays a critical role in total cost of ownership. Ryson Spirals use a single, continuous belt with fewer moving parts than modular conveyor systems. As a result, maintenance requirements can drop by 30-40 %. Fewer wear components reduce unplanned downtime, limit spare parts inventory, and extend service intervals. In high-throughput operations, avoiding even a few hours of downtime each year can protect substantial revenue.

Flexibility

Flexibility

Future-proofing further protects long-term capital investment. Ryson Spirals can be reconfigured, repurposed, or relocated as operational needs change. Instead of replacing equipment, operators extend its useful life. At the end of service, major components remain recyclable, reducing disposal costs and supporting sustainability goals.

Taken together, these advantages change the cost conversation. Ryson Spirals may not always carry the lowest initial price. However, when space savings, energy efficiency, reliability, and adaptability are considered, the Ryson Spiral consistently delivers a lower total cost of ownership.