Spiral Conveyor Automatic Chain Tensioner Reduces Maintenance Down-Time.

Spiral Conveyor Automatic Chain Tensioner Reduces Maintenance Down-Time.

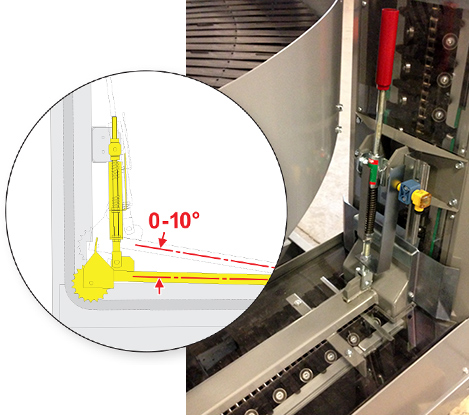

All Ryson Spirals are equipped with an automatic chain tensioner that ensures the chain is in proper tension at all times. The chain will stretch over time – especially during the break-in period of the first 200 – 400 hours of operation. – The chain tensioner takes up the slack, eliminating the need for frequent chain shortening. A sensor will detect when the chain has stretched to the point where the chain needs to be shortened.

The proprietary chain slat design of the Ryson Spiral Conveyors is an efficient low friction system that is low maintenance with a long life. Shortening the chain of a Ryson Spiral is a simple process that can be done in a few minutes, reducing your production down-time. There are several master links in the chain-slats and are clearly marked. You can download Ryson’s detailed chain shortening guide here. Ryson Spirals are the only vertical slat spiral elevator that uses an automatic chain tensioner as standard.