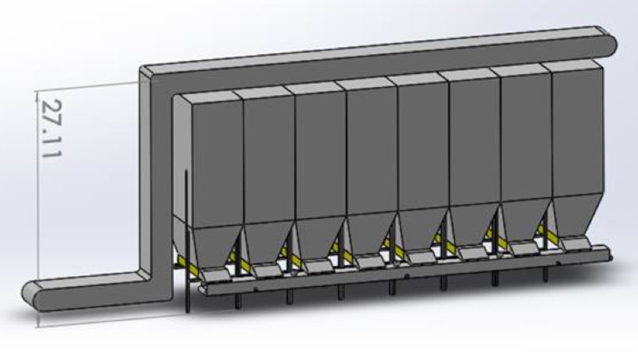

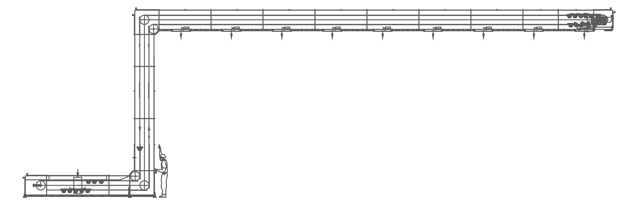

This week we are shipping a bucket elevator with nine discharge points for a special application.

The customer needed to elevate light-weight cellulose material 23 feet to feed nine hoppers in a line. While the overall weight per hour of the light-weight cellulose material (2500 lb/hr) may seem easy to do, the fact that the bulk density is less than 3 lb/ft3 means that the volume is 1000 ft3/hr.

The customer needed to elevate light-weight cellulose material 23 feet to feed nine hoppers in a line. While the overall weight per hour of the light-weight cellulose material (2500 lb/hr) may seem easy to do, the fact that the bulk density is less than 3 lb/ft3 means that the volume is 1000 ft3/hr.

The volume requirements called for the Ryson Z-600-1-9 unit. The first eight discharge locations are pneumatically operated and selectively controlled. The last tipping ramp stays in a fixed position to assure that all buckets are emptied.

The Ryson Bucket Elevators combine vertical and horizontal transportation of bulk material in one integral unit. Their modular design and rugged construction make them suitable for a wide variety of applications. Available in powder coated carbon steel, stainless steel or wash-down versions. For more information, visit www.ryson.com or download the Bucket Elevator Spec Sheet. Read more stories about the Ryson Bucket Elevator on our weekly blog.

The Ryson Bucket Elevators combine vertical and horizontal transportation of bulk material in one integral unit. Their modular design and rugged construction make them suitable for a wide variety of applications. Available in powder coated carbon steel, stainless steel or wash-down versions. For more information, visit www.ryson.com or download the Bucket Elevator Spec Sheet. Read more stories about the Ryson Bucket Elevator on our weekly blog.