Warehousing and order-picking operations often handle larger and heavier loads of varied sizes. It is an ideal application for Space Saving Ryson Spiral Conveyors.

When considering square footage in a large distribution center, the Ryson Spiral Conveyors can be space saving, and can maximize the area for storage and pick module locations. Since the spirals convey straight up and down, they can be placed at the end of a pick line to help create a cleaner more efficient layout and can even help create aisle space.

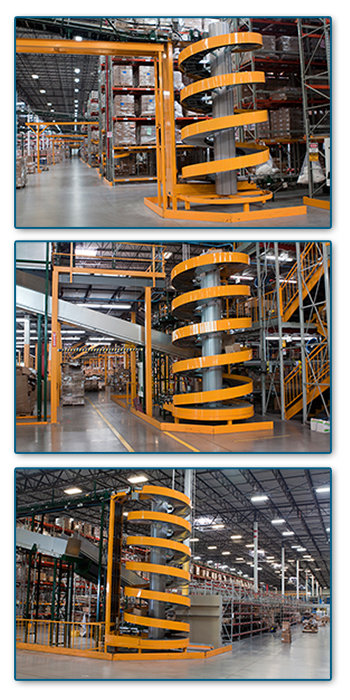

In the order-picking operation shown to the right, our integrator partner Dematic Corporation, designed a distribution center with several muilti-level pick modules, all connected with space-saving Ryson Spirals.

The conventional inclines and belt curves that would be needed to elevate totes and cartons in this end-of-aisle pick module layout would have taken much more floorspace. It would also cost more in implementation and field wiring because of multiple bed sections, motors and control devices. Plus it would cost the end-user more every month in energy bills. Compare one spiral motor to six powered conveyor bed sections, and you’ll see why Ryson Spiral Conveyors help lower the total cost of ownership.