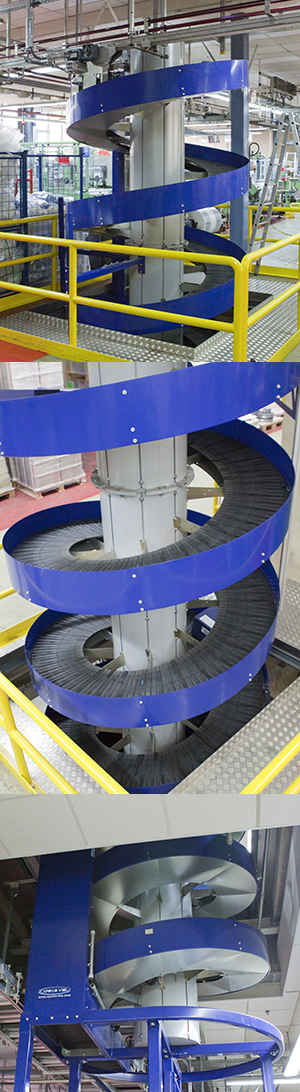

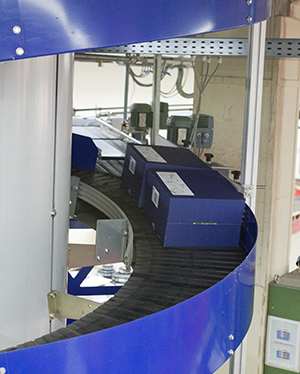

Here is a great example of how a single Ryson Spiral Conveyor can span multiple levels of production. This tall down-spiral collects cases from the third floor production area, and conveys them through a hole in the floor towards the ground level. On the second floor, an induction conveyor merges cartons from the second level production area into the spiral.The conveyor then drops through the ceiling to an over-head conveyor system on the first floor which brings the mixed product cases to a sortation center and palletizer.

Here is a great example of how a single Ryson Spiral Conveyor can span multiple levels of production. This tall down-spiral collects cases from the third floor production area, and conveys them through a hole in the floor towards the ground level. On the second floor, an induction conveyor merges cartons from the second level production area into the spiral.The conveyor then drops through the ceiling to an over-head conveyor system on the first floor which brings the mixed product cases to a sortation center and palletizer.

The system has the ability to convey product from all production lines from levels two and three down to the palletizing level with a single spiral. This application saves valuable floor space and reduces the need for multiple vertical conveying systems.

Ryson’s sister company, Apollo BV – based in Holland, implemented this spiral application at a household plastic manufacturing plant in Nothern Germany.