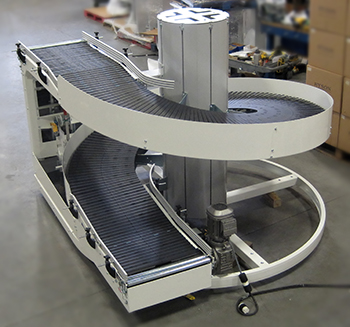

Ryson spirals are all about elevation change in a small area. Here is a short Spiral Conveyor that illustrates this very well.

Most spirals we manufacture are tall, typically going from floor to floor or mezzanine. Even though the pictured spiral only has a 2′-0″ elevation change, it was the only viable solution due to floor space limitations and existing conveyor. A conventional incline conveyor would not fit.

Most spirals we manufacture are tall, typically going from floor to floor or mezzanine. Even though the pictured spiral only has a 2′-0″ elevation change, it was the only viable solution due to floor space limitations and existing conveyor. A conventional incline conveyor would not fit.

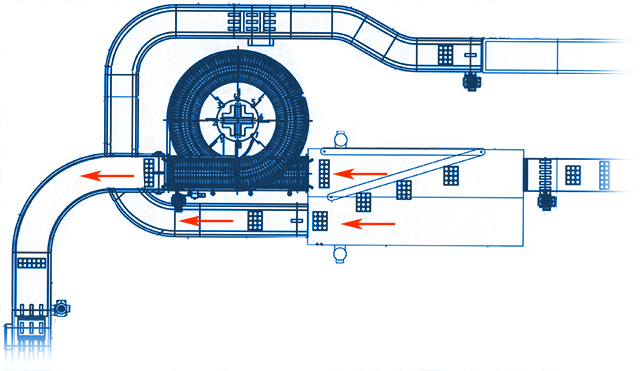

Our integration partner FGWA (Lynchburg, VA) came up with this spiral conveyor solution for a beverage co-packer customer. They needed to split the line after the cartooning/shrink-wrap machine into two case packers, depending on package type. The spiral conveyor was able to elevate one of the lines enough to cross over the other existing conveyors, perfectly utilizing the available space.

You can download the product sheet for the Ryson Spiral Conveyors, or find out more at ryson.com.