In the recent years, Ryson Spirals have been specified to replace older vertical conveying equipment. Our Spirals perform the same function, but often with more reliability and a smaller footprint. Ryson equipment therefore helps lower the total cost of ownership and increases the ROI. Our machines have been replacing outdated equipment by end-users, and also our integrator partners are finding opportunities for improvement with their customers.

In the recent years, Ryson Spirals have been specified to replace older vertical conveying equipment. Our Spirals perform the same function, but often with more reliability and a smaller footprint. Ryson equipment therefore helps lower the total cost of ownership and increases the ROI. Our machines have been replacing outdated equipment by end-users, and also our integrator partners are finding opportunities for improvement with their customers.

Ryson Equipment stands out for these advantages:

- Vertical conveyance using the smallest footprint possible.

- Achieving a high throughput rather than having a cycle time that hinders performance.

- Reliability with a very high up time. It’s something we bring from our decades of experience in the packaging and manufacturing to the warehousing world.

- Delivering a product that is installation and maintenance friendly

- Operating at low noise levels (under 75 dB) using 1 motor for efficiency and lower energy consumption

- Modularity to help future-proof the equipment

Ryson Spirals Replacing Case Lifts

Unlike conventional elevators or lifts, which often require more space and have limited throughput, Ryson Spiral Conveyors provide a compact, high-capacity alternative. They enable faster product movement without the need for stops or waiting, streamlining operations and improving efficiency in vertical product transport. In the first image we see an old case elevator with a low throughput being replaced by a Ryson Spiral for an optimal streamlined and fast process.

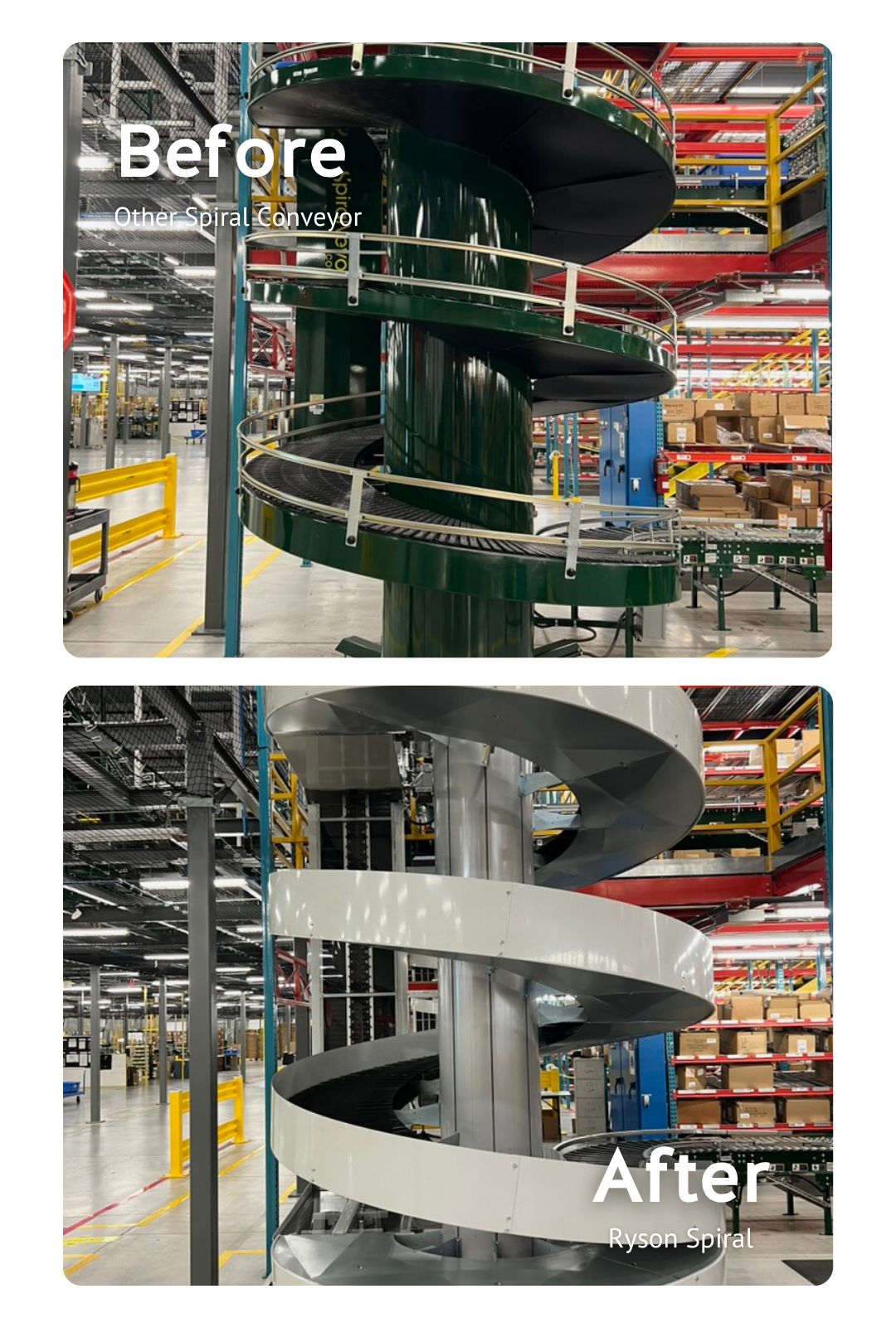

Ryson Spirals Replacing Other Spiral Conveyors

Ryson Spirals Replacing Other Spiral Conveyors

Ryson Spirals have been replacing other spirals in the field for years. They stand out from other brands due to their robust construction, modular design and smooth operation. Moreover they are able to a handle high-speed and continuous product flow without interruption. They’re designed to last, reducing maintenance and downtime. Their modularity (our spirals are bolted, not welded) also makes it easy to make field changes and reconfigurations at any time.

All in all they are a valuable upgrade for facilities seeking a more reliable vertical conveying solution.

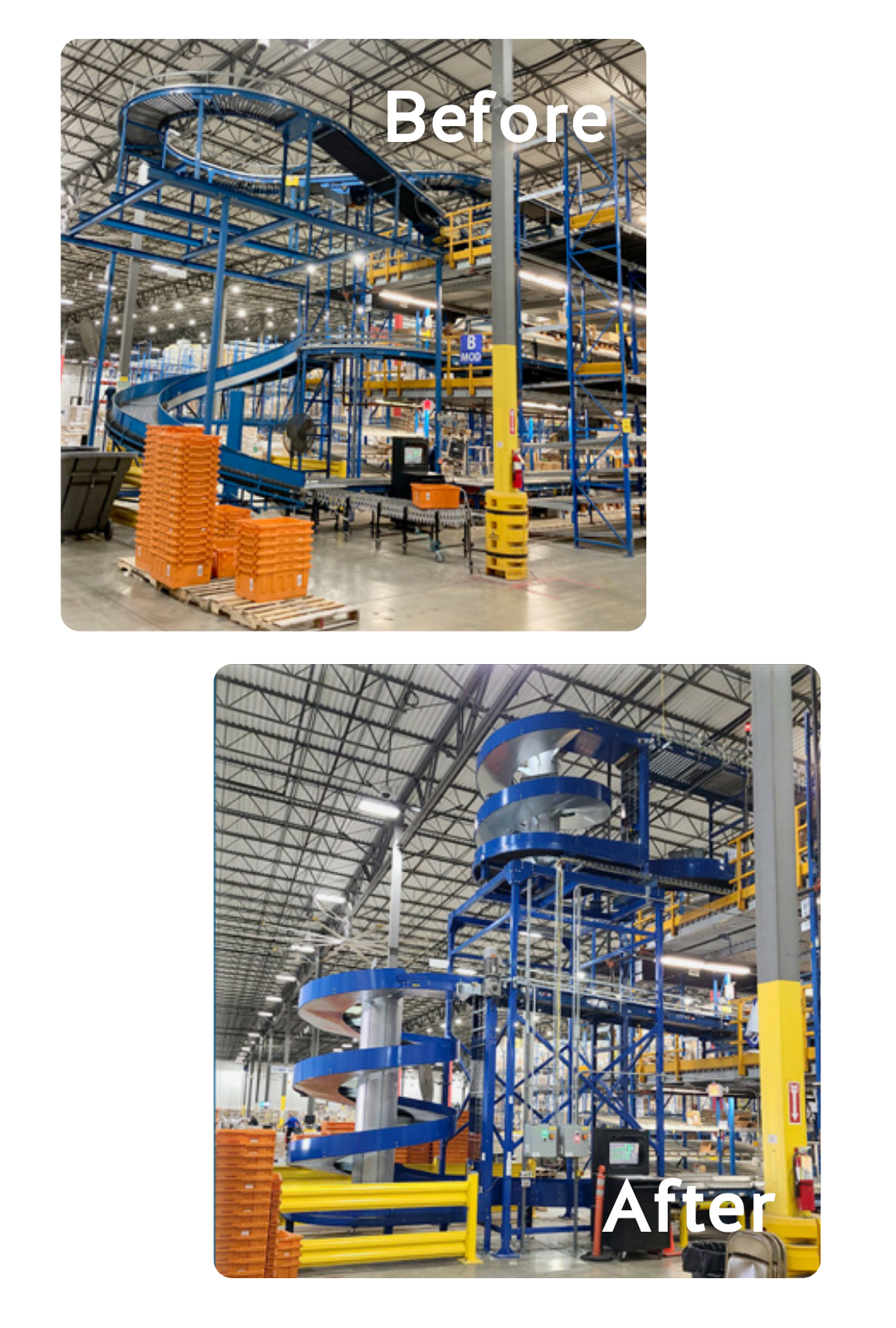

Replacing Curved Conveyors or Gravity Spirals

Replacing Curved Conveyors or Gravity Spirals

In this example, our integrator partner MHS Global with a recommendation from our client Tech Data have teamed up to replace most of their existing vertical conveying equipment and incline belts with Ryson Spirals. The main reason for the upgrade was that the existing equipment was constantly breaking down, which in turn led to a lot of lost time and strain on their maintenance department.

The swap was straight forward, and the integration happened over a weekend. These units were shipped fully assembled (model 1700-600) and will convey a product that is 30” tall. This model can start and stop fully leaded with a maximum capacity of 1,800 lbs. There is also a high-capacity version of these units than can handle up to 3,600 lbs.

For more information or if you have similar challenge, please visit our website and fill in the Request information form.