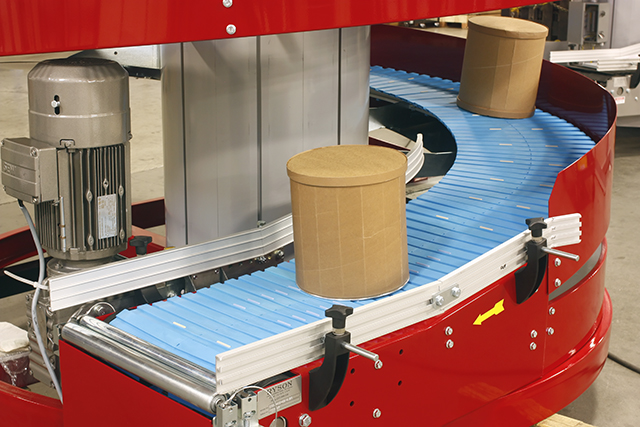

The Ryson Spiral conveyor can be manufactured to operate in a Freezer environment down to -30 degrees. The spiral conveyor is a logical choice for declining frozen product to a robotic palletizer or downstream packaging line. When compared to other methods like belt declines and vertical case lowerators, the Ryson Spiral design is very reliable for this harsh freezer environment. The blue slats are a proprietary compound developed by Ryson to operate in low temperatures and not be brittle.

We recently shipped a special cold spiral for handling large tubs of Ice Cream in a freezer (minus 10 degrees F) at a large Ice Cream manufacturer in the Midwest by our Systems Integrator, Engineered Packaging Systems of Addison, Illinois. The above photo was taken in our manufacturing plant during testing prior to shipping. This spiral joins many other Ryson spirals in use in sub-zero environments across North America.