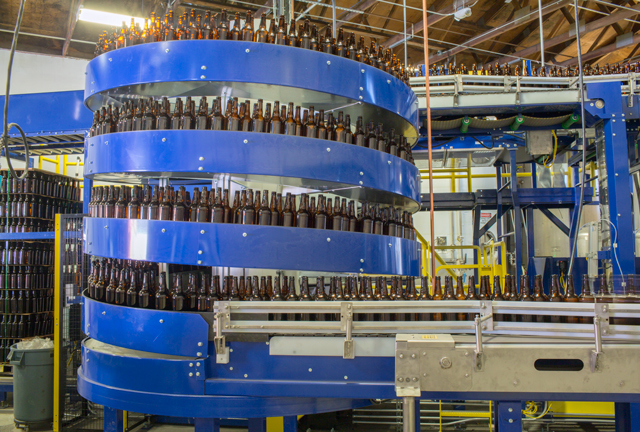

We recently completed a project with a Ryson mass flow spiral used for a bulk depalletizing tool for our Integrator partner, Foth Production Solutions.

Empty Glass bottles are being fed from a Can Lines Bulk Depalletizer to our 1900-260 mass flow spiral, which declines them down to the filler level. This has become a very popular spiral model with bulk depalletizing, because it saves space, while able to transport the taller 20 & 22 ounce glass bottles commonly used by craft breweries.

This model (with a 10” wide slat surface) is capable of capacities of 800 bottles or cans per minute. It’s big brothers (16” and 20” wide slat surface) are capable of 1,200 and 2,000 bottles per minute respectively.

The Ryson mass flow spirals are a money saver, because the modest decline angle required for a conventional decline conveyor would create the need for much more floor space, along with multiple drives and higher implementation costs. Gripper lowerators do not have the capacity to handle the fill rates of most modern production lines. View more application stories where Ryson Spirals were used in bottling on our weekly blog.