Ryson’s Bucket Elevator continues to prove itself as a flexible and efficient solution for conveying bulk materials.

Ryson’s Bucket Elevator continues to prove itself as a flexible and efficient solution for conveying bulk materials.

Its modular design stands out as a major advantage, delivering adaptability, ease of transport, and simplified on-site assembly — all tailored to meet the specific needs of your application.

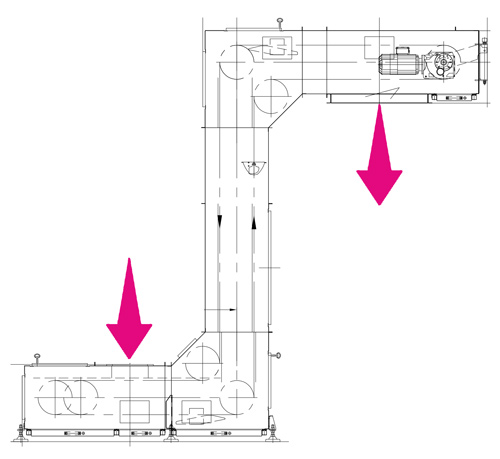

This week we are shipping a pair of bucket elevators that will be processing bird seed. The project integrator is Cisco-Eagle. The end user needed to transport birdseed to a hopper that feeds a bagger, for final packaging. The two model 200 units will transport 12,000 bird seed per hour each, with transporting the seed vertically eleven feet.

Cisco- Eagle’s customer needed to upgrade their packaging line so they specified two Ryson Bucket Elevators. They will also gently handle the material so as to reduce breakage and maintain better dust control.

Built to Fit Your Application

Every facility has different layout requirements and material handling needs. That’s why the Ryson Bucket Elevator is engineered with modularity in mind — allowing each unit to be configured to the exact specifications of the customer. Whether your setup calls for multiple infeed points, discharge points, or a unique conveying path, the Ryson Bucket Elevator can be designed accordingly.

This application-specific approach not only ensures seamless integration into your production line. It also minimizes wasted space — an important factor in operations where floor space is limited.

Efficient Shipping and Easy Installation

Another key benefit of the modular design is its impact on logistics. Ryson Bucket Elevators are shipped in sections, making them easier and more cost-effective to transport. Each component is match-marked to assist with fast and accurate reassembly on site.

Another key benefit of the modular design is its impact on logistics. Ryson Bucket Elevators are shipped in sections, making them easier and more cost-effective to transport. Each component is match-marked to assist with fast and accurate reassembly on site.

This modular approach significantly reduces installation time and complexity. Whether you’re setting up in a tight space or coordinating around existing equipment… The Bucket Elevator’s thoughtful design makes the process more manageable.

Built to Handle a Variety of Materials

Versatility isn’t just in the configuration — it’s also in what the Bucket Elevator can handle. Ryson’s solution is ideal for a wide range of bulk materials, including:

-

Fine powders and grains

Fine powders and grains -

Granular and flaky substances

-

Recycled materials and abrasives

-

Glass and other industrial compounds

This makes the Bucket Elevator a trusted choice across industries as diverse as baking and food production, industrial processing, agriculture, recycling, and even scientific or laboratory-based operations.

Designed for Reliability

Whether you’re moving delicate ingredients or rugged recycled goods, the Ryson Bucket Elevator is built for smooth, dependable operation. The gentle handling mechanism ensures product integrity, while the fully enclosed design keeps spillage and contamination in check.

If you’re looking for a bucket elevator that adapts to your space, supports multiple configurations, and handles a wide variety of materials — Ryson’s modular approach might be the perfect fit.

www.ryson.com, download the product information or read other bucket elevator stories on our weekly blog.