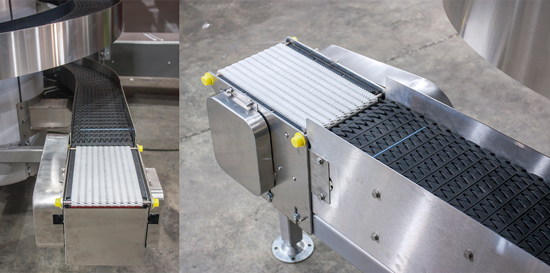

The micro-pitch conveyor is our newest accessory to the Narrow Trak family of spiral conveyors.

This micro-pitch transfer conveyor is slave-driven off the drive or idle-end shafts and is geared to match the speed of the spiral- perfectly – even at high speeds.

This transfer unit minimizes the unpowered gap between the spiral and adjoining conveyors, allowing smaller and lighter products to be end transferred into and out of the spiral. When end transferring the slats can be equipped with friction inserts to provide more friction. This allows steeper incline/decline angles which yields greater elevation changes with the same number of turns.

The Narrow Trak spirals are available in a 6” and 9” wide nesting slat design. The proprietary slat design have the capacity to reliably end-transfer small cartons and packages or side-transfer small bottles and containers in a single file or in a continuous mass flow. The Ryson Narrow Trak Spirals are great space savers with high throughput that can run at speeds in excess of 200 fpm.

The transfer unit is available in either a powder coated or stainless steel versions. For more information on the Ryson Narrow Trak Spiral conveyors, visit www.ryson.com, or download the NT product brochure.