Ryson makes Integrator Partnerships a priority at all stages of a project. We strive to return a RFQ within 24 hours. The Ryson Team then works with our customers to come up with an ideal solution to the project. We are willing to cooperate and help design the ideal solution with our Vertical Conveying Solutions. But our involvement continues past the on-time delivery of a high quality product. Our parts and service team is always there to help with installation, maintenance and the long-term continued health of your investment.

Ryson makes Integrator Partnerships a priority at all stages of a project. We strive to return a RFQ within 24 hours. The Ryson Team then works with our customers to come up with an ideal solution to the project. We are willing to cooperate and help design the ideal solution with our Vertical Conveying Solutions. But our involvement continues past the on-time delivery of a high quality product. Our parts and service team is always there to help with installation, maintenance and the long-term continued health of your investment.

This commitment is highlighted in our relationship with our integrator partners. We know you are often pressed from everything from a tight proposal deadline to unwavering support during implementation and launch. Our integrator partners know that Ryson is with them every step of the way.

Integrator Partnership Story:

Take for example our partners at Multi-Conveyor: We just completed a high-profile application with them. Not only were we there from the first planning stages, we helped facilitate launch and start-up.

Take for example our partners at Multi-Conveyor: We just completed a high-profile application with them. Not only were we there from the first planning stages, we helped facilitate launch and start-up.

“While Multi-Conveyor has its own limited spiral manufacturing capability, Ryson is a “go to” spiral manufacturer when the parameters of the application may exceed our in-house capabilities. We have chosen to include Ryson on many projects that involve carton and case handling where elevation changes are required in a compact area. Ryson provides their applications engineering expertise and competitive quotes for our fast-paced environment. Most importantly, they deliver reliable equipment that interfaces with our systems that both Multi-Conveyor and our end users know will have exceptional quality and performance.“ – Jim Paulsen, Sr. Sales Account Manager, Multi-Conveyor

The added advantage to having a close partnership like this is that our marketing teams can also work together to cross-promote note-worthy projects. Take for example the great press that Multi-Conveyor got with a recent project involving Ryson.

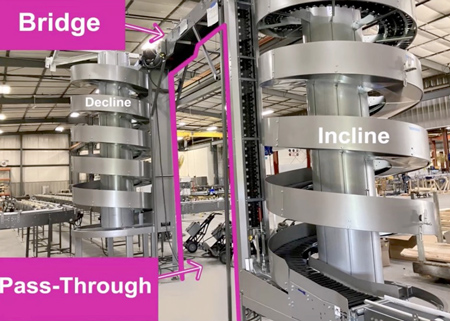

The project involves over 200 feet of accumulation. It is designed to transport and accumulate product from several cartoner discharges to feed downstream packaging operations. Included in this accumulation are 2 Ryson Spirals that provide an access point through the conveyor line. It also provides accumulation vertically to help reduce the total footprint of the operation. Check out their video on the entire application.

In Packaging, most spirals are used to transport goods from primary packaging to storage, or palletizing. But they are also ideal solutions to provide Vertical Accumulation. One Spiral elevates the product, and right next to it is a Spiral that brings it back down. This can also be used when a product needs time for curing or cooling.

In Packaging, most spirals are used to transport goods from primary packaging to storage, or palletizing. But they are also ideal solutions to provide Vertical Accumulation. One Spiral elevates the product, and right next to it is a Spiral that brings it back down. This can also be used when a product needs time for curing or cooling.

The Power of Partnerships: How Cooperation Fuels Success in Vertical Conveying

In today’s fast-paced industrial landscape, collaboration is more than just a buzzword—it’s a necessity. Nowhere is this more evident than in the world of vertical conveying, where integrators and suppliers must work hand in hand to deliver superior solutions. Strong partnerships built on trust, problem-solving, and mutual respect create an environment where innovation thrives and clients receive the best possible results.

In the vertical conveying industry, integrators and OEMs must recognize that their success is intertwined. A strong partnership leads to more reliable systems, better service, and greater customer satisfaction. End users benefit from higher-quality solutions that are delivered on time and within budget, while both integrators and Ryson strengthen their market positions through reputation and repeat business.

At its core, partnership is about more than just completing a project—it’s about building a legacy of trust, innovation, and problem-solving that fuels long-term success.

Lastly, you can find Ryson (booth 1015) and Multi-Conveyor (booth 908) at Pack Expo Southeast in a few weeks. Be sure to visit Multi-Conveyor at the opening reception.