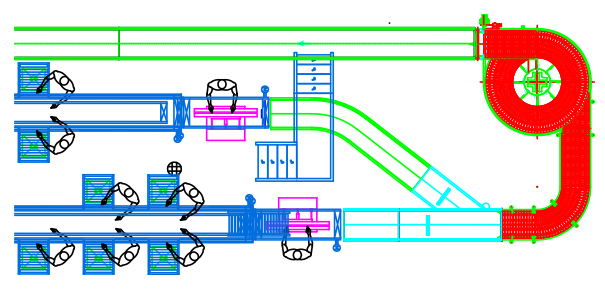

Ryson’s proprietary chain-slat arrangement allows their spiral conveyor to extend the infeed and/or outfeet, which can save floorspace and reduce ancillary conveyors.

On a recent project, our integrator – Advanced Equipment Company of Charlotte, NC – used that flexibile feature to fill in between the existing conveyor and the spiral. This curved extended infeed saved them an extra drive section, which saved the client – a large food processing firm -both implementation and on-going energy costs. This extended infeed is driven by the spiral conveyor’s only motor and didn’t add required horsepower, due to the Ryson rolling friction design. This spiral was built in stainless steel operating in a wash-down environment, and is an option on all our spiral conveyor models.

The proprietary design of our spiral conveyor and it’s overlapping slat-style chain allows the slats to flex in either direction, so infeed extensions can curve in any direction as far as 30 feet.

You can download the Ryson Spiral configurations chart here, or for more information about spiral conveyors, visit www.ryson.com.