The Ryson Dual Track Spiral Conveyor allows two production lines to be conveyed inside one spiral.

The Ryson Dual Track Spiral Conveyor allows two production lines to be conveyed inside one spiral.

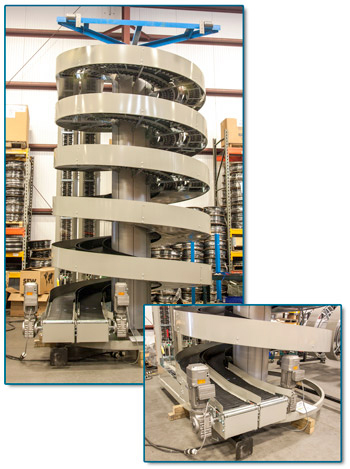

This week we shipped three spiral conveyors to a food manufacturer in the South Atlantic area for our System Integrator, Motion Controls Robotics.

In their system design, they used two of our Model 1200-300 spirals to elevate sealed cases from two separate production lines, that were then transported to a Robotic Palletizer.

Because of space limitations near the palletizer, they chose our Dual Track Spiral to decline the cases down from a 16’-0” elevation to the floor level. Each lane on the dual is individually driven and controlled, giving them flexibility in the flow of product from each production line.

These spirals were shipped fully-assembled, minimizing implementation time and field installation costs.

For more information on the Ryson Dual Track Spiral Conveyors, Visit www.ryson.com, or download the Dual Track Spec Sheet. You can also read more blog stories on the Ryson Dual Track Spiral.