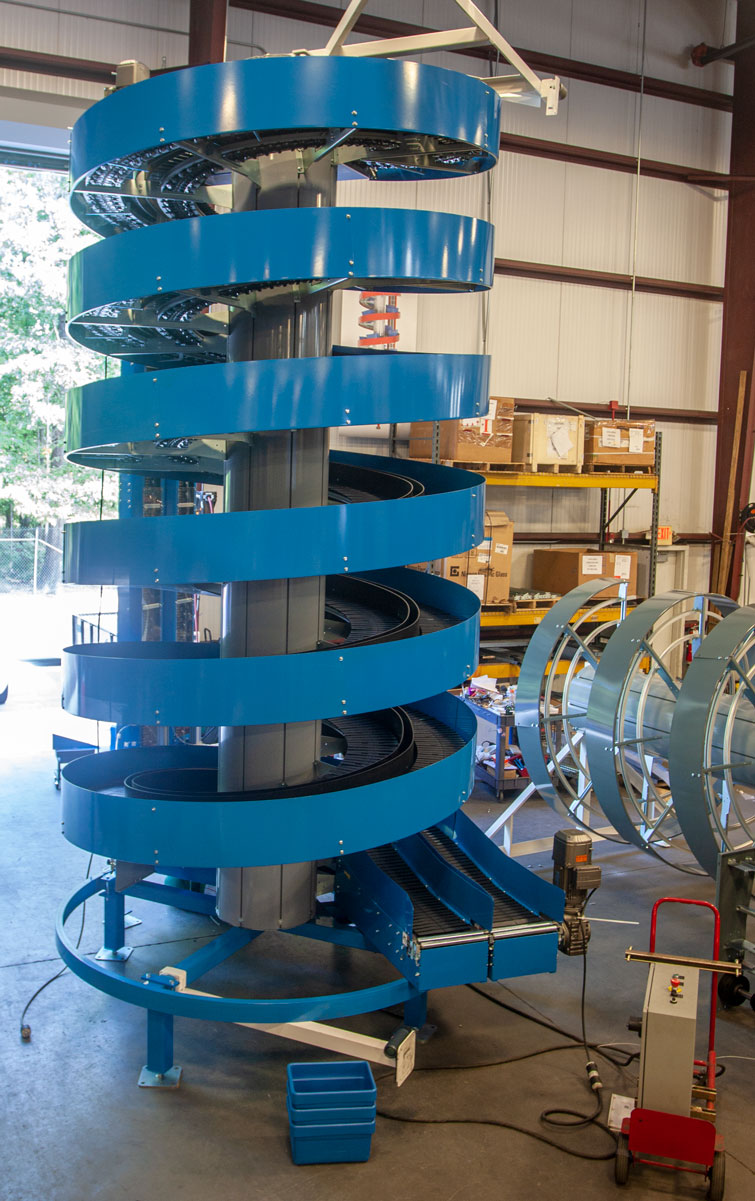

A Couple of weeks ago we shipped 3 Dual Spirals to one of the biggest pharmaceutical companies in the US.

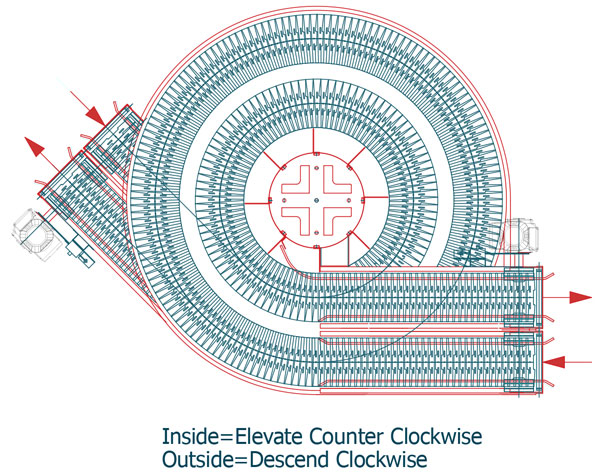

This facility already has several of our spirals, but with a plant expansion, they needed more vertical conveying. The main highlight of these spirals is that the lanes are independently driven. The inside lane elevates totes with product to a processing area on the second story. The totes then return back down on the outside track and are transported to the next process area.

Interestingly, this initial design of this project started off with twelve single spirals – six up and six down. But due to space constraints and budgetary considerations, the final design specified 3 bi-directional Dual Track Spirals. This solution was less expensive and still achieved the throughput requirements.

Interestingly, this initial design of this project started off with twelve single spirals – six up and six down. But due to space constraints and budgetary considerations, the final design specified 3 bi-directional Dual Track Spirals. This solution was less expensive and still achieved the throughput requirements.

Each of these units feature two 12″ conveying surfaces that operate independently. They will convey open totes (15”x11”) at a speeds of 125 fpm. Also, the elevation change will be about 15’ feet. These units shipped fully assembled from our Yorktown, VA plant.

Also, one of the spirals in this project features a custom infeed tangent (photo). It is a readily available option for all our spirals – including our Dual Track Spirals. This helps optimize floorspace by eliminating ancillary adjoining conveyors and additional controls.

This project was implemented by our integrator partner Bastian Solutions for a project located in Florida. They were set in place, mechanically installed and ready for commissioning in the same day.

Our Dual Spirals are the ultimate in space savings.

This application is a perfect example. When using them for bi-directional transportation, you get an up and a down spiral within the same frame.

For more information about Ryson’s line of Dual track spirals, check out www.ryson.com, or read more dual track application stories in our weekly blog.