Today’s production and warehousing environments demand efficient, flexible, and sustainable equipment. Ryson Spiral Conveyors meet those demands as SMART vertical conveying systems. They optimize space, reduce energy use, and deliver consistent performance.

Here’s what makes these Spiral Conveyors truly S.M.A.R.T.

Sustainability

Sustainability

Ryson Spirals focus on energy efficiency and long-term value. Their low-friction design reduces power consumption and limits wear. Each spiral runs on a single motor, which simplifies operation and lowers energy demand.

Ryson builds every Spiral using aluminum and steel. Both materials rank among the most recyclable and resource-efficient available. Fewer moving parts also mean fewer replacements over time. As a result, maintenance needs drop and service life increases.

Ryson builds every Spiral using aluminum and steel. Both materials rank among the most recyclable and resource-efficient available. Fewer moving parts also mean fewer replacements over time. As a result, maintenance needs drop and service life increases.

Together, these benefits reduce environmental impact and lower total cost of ownership. Sustainability becomes a built-in advantage, not an added feature.

Learn more about our sustainability efforts.

Modularity

Modularity

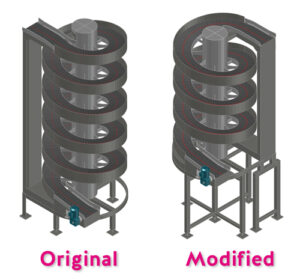

No two facilities operate the same way. That’s why Ryson Spirals feature a modular design. Each unit adapts to existing conveyor lines and evolving layouts.

Facilities can reconfigure Spirals as production needs change. Instead of replacing equipment, teams reuse existing systems. This approach saves time, reduces waste, and protects capital investments.

Modularity allows your conveyor system to grow with your operation, not restrict it.

Adaptability

Adaptability

Ryson Spirals handle a wide range of products with smooth, continuous flow. They support applications across food and beverage, e-commerce, packaging, and distribution. They are ideal for modernization projects.

Their compact footprint makes them ideal for upgrade projects because Spirals fit into tight spaces where traditional conveyors might struggle. Replacing outdated equipment can also drastically increase throughput and helps minimize disruptions. Facilities often gain throughput while reducing floor space.

Reliability

Reliability

Downtime costs money.

Downtime costs money and disrupts schedules.

Ryson Spirals deliver proven reliability across global installations. Precision engineering and high-quality components support continuous operation. Decades of experience reinforce every design decision.

If issues arise, Ryson’s service and spare parts teams respond quickly. Support remains dependable long after installation.

Technology

Technology

Innovation drives every Ryson Spiral. Integrated controls and smart configurations support modern production environments. Digital-ready designs prepare systems for future upgrades.

This focus on technology ensures your vertical conveying system stays relevant as operations evolve.

Choosing a Ryson SMART Spiral means investing in sustainability, flexibility, and long-term reliability. Read more detailed information on our SMART Spiral in this informative White Paper.

Connect with our team if you’re interested to learn more.