Link to SEW Motor

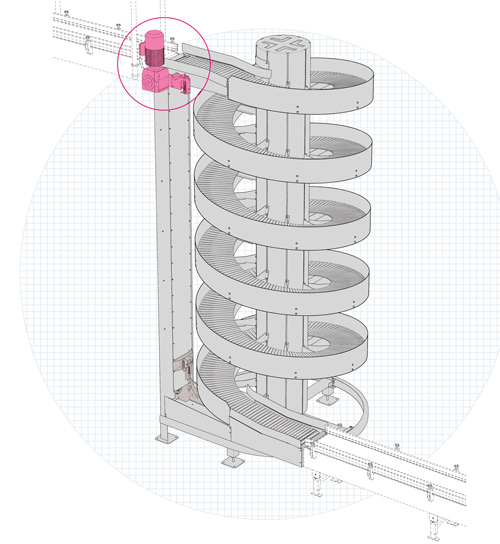

In today’s competitive marketplace, companies are seeking every advantage to reduce costs and improve sustainability. At Ryson, we’ve taken Spiral Efficiency to the next level by optionally equipping our Spiral Conveyors with SEW’s new DR2C IE5 motors. This powerful combination directly supports lower operating costs while advancing sustainable operations.

In today’s competitive marketplace, companies are seeking every advantage to reduce costs and improve sustainability. At Ryson, we’ve taken Spiral Efficiency to the next level by optionally equipping our Spiral Conveyors with SEW’s new DR2C IE5 motors. This powerful combination directly supports lower operating costs while advancing sustainable operations.

The DR2C IE5 motor is engineered to cut energy losses by 50% compared to conventional motors. For operations that rely on frequent starts, stops, or variable loads—like e-commerce fulfillment centers, intralogistics, or food and beverage plants—this level of Spiral Efficiency translates into measurable savings on energy bills without reducing throughput.

Compact design also plays a role in efficiency. The motor’s interior permanent magnet technology delivers higher power density in a smaller footprint. For facilities already saving space with Ryson Spirals, this creates an even leaner installation. Combined with long service life and reduced maintenance needs, Spiral Efficiency becomes not only about energy but also about reliability and long-term savings.

Sustainability is another dimension of Spiral Efficiency. The IE5 motor requires half the amount of electrical steel and aluminum compared to older designs. This reduces both energy consumption and raw material demand—aligning your conveyors with ESG initiatives and corporate sustainability targets.

“Ryson’s strategic partnership with SEW has been a valuable asset. They are always willing to work with us to meet the rigorous demands of our production team. We are all excited to make their new line of motors available on our equipment.” Dave Wineman – President, Ryson International.

![]() Future-ready integration makes the DR2C IE5 motor even more attractive. It works seamlessly with SEW’s MOVI-C® modular system, ensuring conveyors remain flexible for changing production demands. With this motor, Spiral Efficiency is about more than energy—it’s about preparing your operation for tomorrow’s challenges. It can also reduce and simplify installation and integration, since the variable frequency drive is built into the motor. Find out more information at SEW.

Future-ready integration makes the DR2C IE5 motor even more attractive. It works seamlessly with SEW’s MOVI-C® modular system, ensuring conveyors remain flexible for changing production demands. With this motor, Spiral Efficiency is about more than energy—it’s about preparing your operation for tomorrow’s challenges. It can also reduce and simplify installation and integration, since the variable frequency drive is built into the motor. Find out more information at SEW.

Download more information on this motor here. We also welcome you discuss this new Spiral Efficiency firsthand at Pack Expo Las Vegas this month. Our team will be available to discuss how Ryson Spirals powered by SEW IE5 motors can cut costs and support your sustainability goals.