Ever seen an entire production line grind to a halt because of spillage or equipment failure?

It’s a sinking feeling—lost time, wasted product, and frustrated teams scrambling to fix the mess.

If that scenario rings a bell, there’s a solution on the market that shatters those nightmares and replaces them with reliability, flexibility, and peace of mind: the Ryson Bucket Elevator.

This isn’t just another conveyor. It’s a made in the US rugged, high-end bucket elevator that leverages pivoting, overlapping buckets and a fully enclosed design to do one thing exceptionally well: keep your materials exactly where they need to be without risking contamination or spillage.

This isn’t just another conveyor. It’s a made in the US rugged, high-end bucket elevator that leverages pivoting, overlapping buckets and a fully enclosed design to do one thing exceptionally well: keep your materials exactly where they need to be without risking contamination or spillage.

Manufactured in Virginia, USA, our machines are engineered for minimal maintenance and maximum uptime, ensuring you’re not left scrambling when it matters most. Plus, with readily available service and spare parts, we keep your operation flowing seamlessly—day in, day out.

Overlapping Pivoting Buckets for Minimal Spillage

One of the most notable features of the Ryson bucket elevator is its rugged design, meticulously engineered to handle various types of products and materials. The unique overlapping pivoting buckets ensure that material spillage is virtually eliminated. These buckets pivot with every movement to stay tightly closed, preventing spillage, cross-contamination, and product loss along the way.

Benefits of Overlapping Pivoting Buckets

- Anti-spillage technology: Keeps materials secure within each bucket.

- Reduced product loss: Prevents costly waste of valuable or delicate materials.

- Gentle handling: Ideal for fragile materials, such as glass fibers or specialty chemicals, where product integrity is crucial.

The Ryson bucket elevator offers a completely enclosed design that seals off your product from external contaminants. This design is pivotal in industries where preventing dust ingress and keeping out other contaminants is critical—not only for product purity but also for employee safety and regulatory compliance.

Industries Benefiting from an Enclosed Design

- Food Processing: Protects against dust, pests, and external contaminants, ensuring product quality.

- Pharmaceuticals: Maintains purity standards by preventing possible contamination.

- Hazardous Materials Handling: Minimizes exposure risks for workers by containing dust and fumes within the system.

- Glass Fiber Manufacturing: Shields delicate glass fibers from external particulates that can compromise strength and quality.

Modular Configurations for Endless Possibilities

Modular Configurations for Endless Possibilities

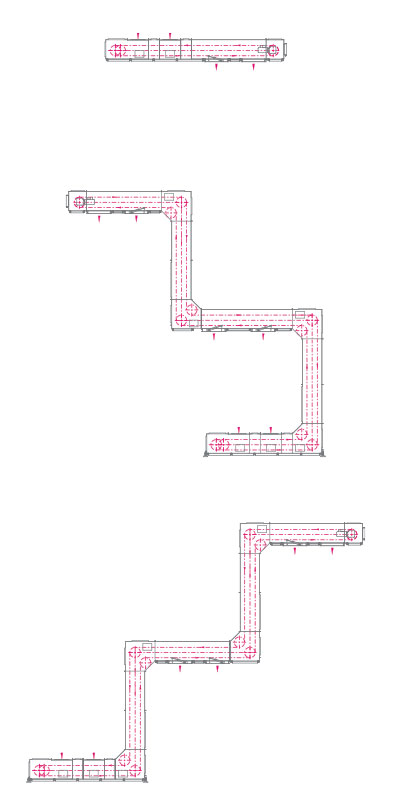

Another key advantage of the Ryson bucket elevator is its modular design, which offers endless layout options to suit your facility’s needs. Whether you require a C-shape configuration, Z-shape layout, or multiple inlets and outfeeds, the rugged bucket elevator from Ryson can be adapted to fit perfectly into your existing production line.

Modular Design Highlights

- Customizable Bucket Styles and Materials: From stainless steel buckets for clean-room environments to heavy-duty polymer buckets for abrasive or corrosive materials.

- Flexible Layouts: Easily integrate various shapes (C, Z, etc.) and additional outfeeds or infeed points to accommodate multiple production stations.

- Scalable Solutions: As your production demands grow, Ryson’s modular system can be expanded or reconfigured with minimal downtime.

Minimal Maintenance and High Reliability

In sectors dealing with hazardous or highly sensitive materials, machine failures can be expensive and potentially dangerous. With a Ryson bucket elevator, you can minimize maintenance requirements while maximizing uptime. The robust construction and proven design reduce the risk of wear and tear, enabling you to trust your equipment to work around the clock, day after day.

Why Reliability Matters

- Worker Safety: Fewer breakdowns mean less need for manual intervention in hazardous zones.

- Cost Efficiency: Prevents costly repairs, unscheduled downtime, and production delays.

- Increased Throughput: Reliable equipment supports continuous, efficient operations, boosting productivity.

Perfect for the Technological and Scientific Sector

Manufacturing processes in the technological and scientific sector, such as glass fiber production, often involve delicate or sensitive materials. The Ryson bucket elevator ensures that these materials are conveyed gently and securely—reducing waste, minimizing contamination, and maintaining product integrity throughout the handling process. This is especially critical in research-intensive or highly specialized environments where consistency and precision are of the utmost importance.

Ideal for Handling Hazardous Materials

When dealing with hazardous materials, safety takes precedence. A completely enclosed, rugged bucket elevator design ensures personnel remain shielded from dust, fumes, or other harmful substances. The high quality bucket elevator structure also reduces the need for frequent repairs or part replacements, minimizing the presence of maintenance personnel near potentially dangerous areas.

Why Choose Ryson for Your Bucket Elevator Needs?

- Rugged Construction: Built to withstand demanding environments with minimal downtime.

- Innovative Bucket Design: Overlapping, pivoting buckets eliminate spillage and contamination risks.

- Enclosed Operation: Protects workers and products from dust, debris, and other external factors.

- Modular Flexibility: Offers a variety of configurations—C-shape, Z-shape, multiple inlets/outlets—to fit your unique space and process needs.

- Minimal Maintenance: Reduces costs and operational disruptions, especially critical in hazardous or delicate production environments.

- Industry Diversity: Suitable for food, pharmaceutical, chemical, technological, and scientific applications, among others.

If you are looking for a rugged, high quality bucket elevator solution for your facility, our Bucket Elevator is the perfect choice. Its robust construction, innovative overlapping bucket design, and customizable configurations ensure optimal performance for various industries—from glass fiber manufacturing in high-tech sectors to heavy-duty operations with hazardous materials.

Upgrade your vertical conveying system with Ryson’s high-performance bucket elevator today and experience the difference in efficiency, safety, and reliability.

Get in touch with our Bucket Elevator Account Manager Bill Keane.

Bill will be happy to provide you with any additional information and quotes. You can also find product brochures and more information on our catalog library page and on our YouTube channel.