Introducing the Ryson Dual 500: Our Largest Dual Track Spiral Conveyor Yet

Ryson International proudly introduces the Dual 500, the newest and largest model in our Dual Track line.

Ryson International proudly introduces the Dual 500, the newest and largest model in our Dual Track line.

The Dual Track 500 delivers unmatched compact efficiency and flexibility for vertical conveying.

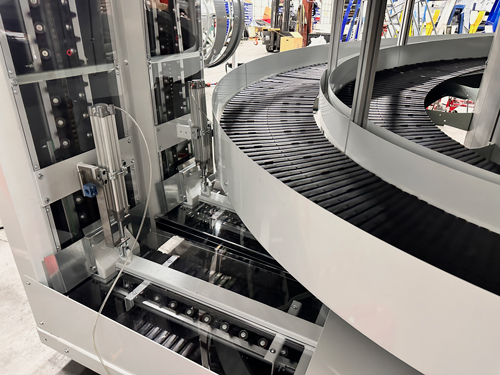

Our Integrator Partner, Van Doren Sales, specified our 1600-500/2800-500 Dual Track Spiral Conveyor to fit a tight space where they needed to lower boxes of fruit from two production lines down to a floor-level sorting system. This two-lane configuration saved significantly more space than installing two separate spirals. The system will handle 60 boxes per minute, operating at 150 feet per minute.

Van Doren also incorporated our multiple-infeed spiral model HC1700-600 to combine three lines into one using an inclining spiral conveyor. One of our technicians visited the site to oversee the reassembly of the dual track spiral and provide startup assistance for the multi-infeed machine.

If you were unaware of our Dual Track line, here are some of the advantages:

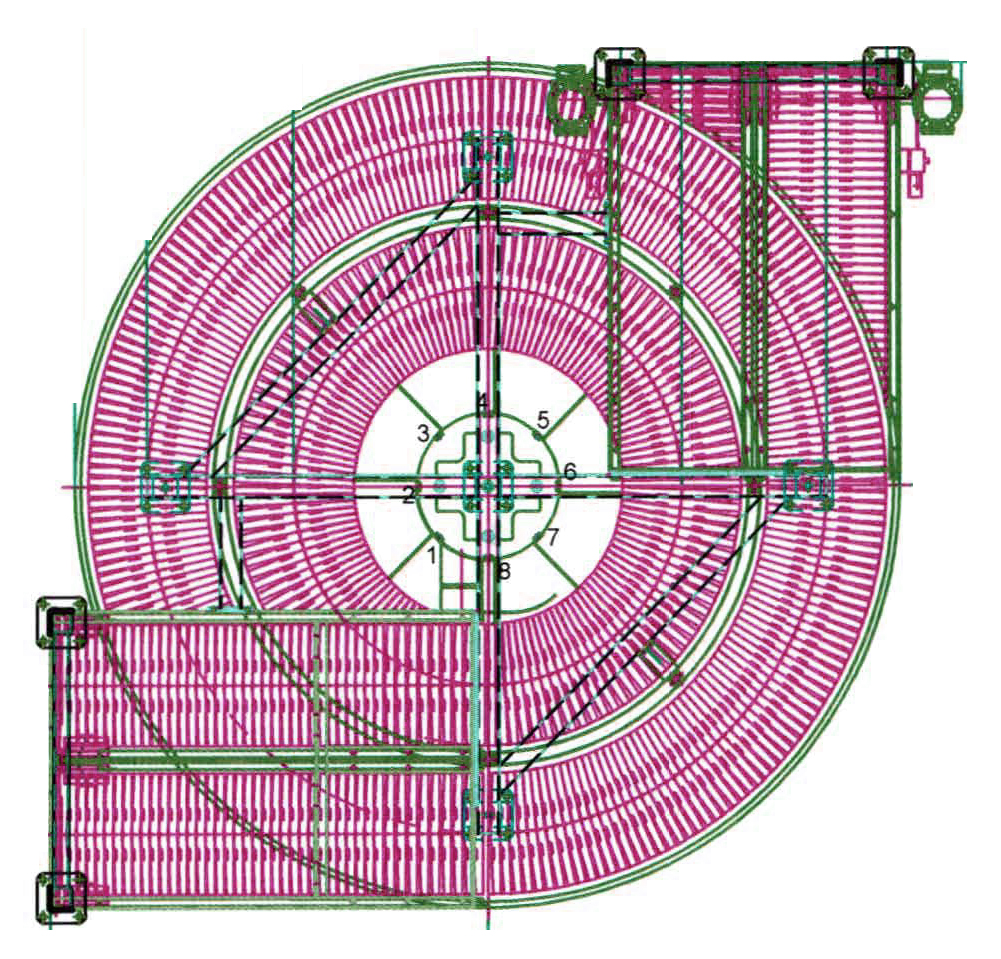

Two Independent Spirals in One Frame

Our Dual Track Spirals feature two completely independent spirals within a single compact frame. This smart design allows two separate product lines to share the same footprint. You can run them at different speeds or in opposite directions. Each line stays fully independent.

Our Dual Track Spirals feature two completely independent spirals within a single compact frame. This smart design allows two separate product lines to share the same footprint. You can run them at different speeds or in opposite directions. Each line stays fully independent.

Flexible Multi-Tier Discharge

Each conveying surface can optionally discharge at a different level. This feature adds flexibility for multi-tier operations. You can streamline production lines, reduce transfers, and improve flow.

Continuous Wide Conveying Surfaces

Each track offers a continuous conveying surface that is 20 inches wide. It also allows you to handle a wide range of products with ease; without the need to make adjustments or have down-time for change parts.

Reversible and Independently Driven

Both conveying surfaces have their own drive systems. You can optionally reverse them independently to meet your workflow needs. The Dual 500 adapts to your processes, not the other way around.

Save Valuable Floor Space

Because the Dual 500 combines two spirals into one frame, it takes up far less floor space than traditional vertical conveyors. You can maximize your facility layout without compromising throughput.

Ready to learn how the Ryson Dual 500 can optimize your operations?

Contact us today to discuss your application.