Food and beverage plants rarely have extra floor space. Production lines grow faster, while layouts stay tight. As a result, manufacturers continue to rely on Vertical Conveying Options that support throughput without disrupting existing operations. Ryson Spirals meet this challenge by combining reliability, flexibility, and a compact footprint that fits demanding environments.

Food and beverage plants rarely have extra floor space. Production lines grow faster, while layouts stay tight. As a result, manufacturers continue to rely on Vertical Conveying Options that support throughput without disrupting existing operations. Ryson Spirals meet this challenge by combining reliability, flexibility, and a compact footprint that fits demanding environments.

Ryson Spirals remain a staple across food and beverage facilities. Their vertical design preserves valuable floor space while keeping products moving smoothly between elevations. Breweries, bottling plants, and packaging operations benefit from predictable flow and consistent uptime, even in wet conditions.

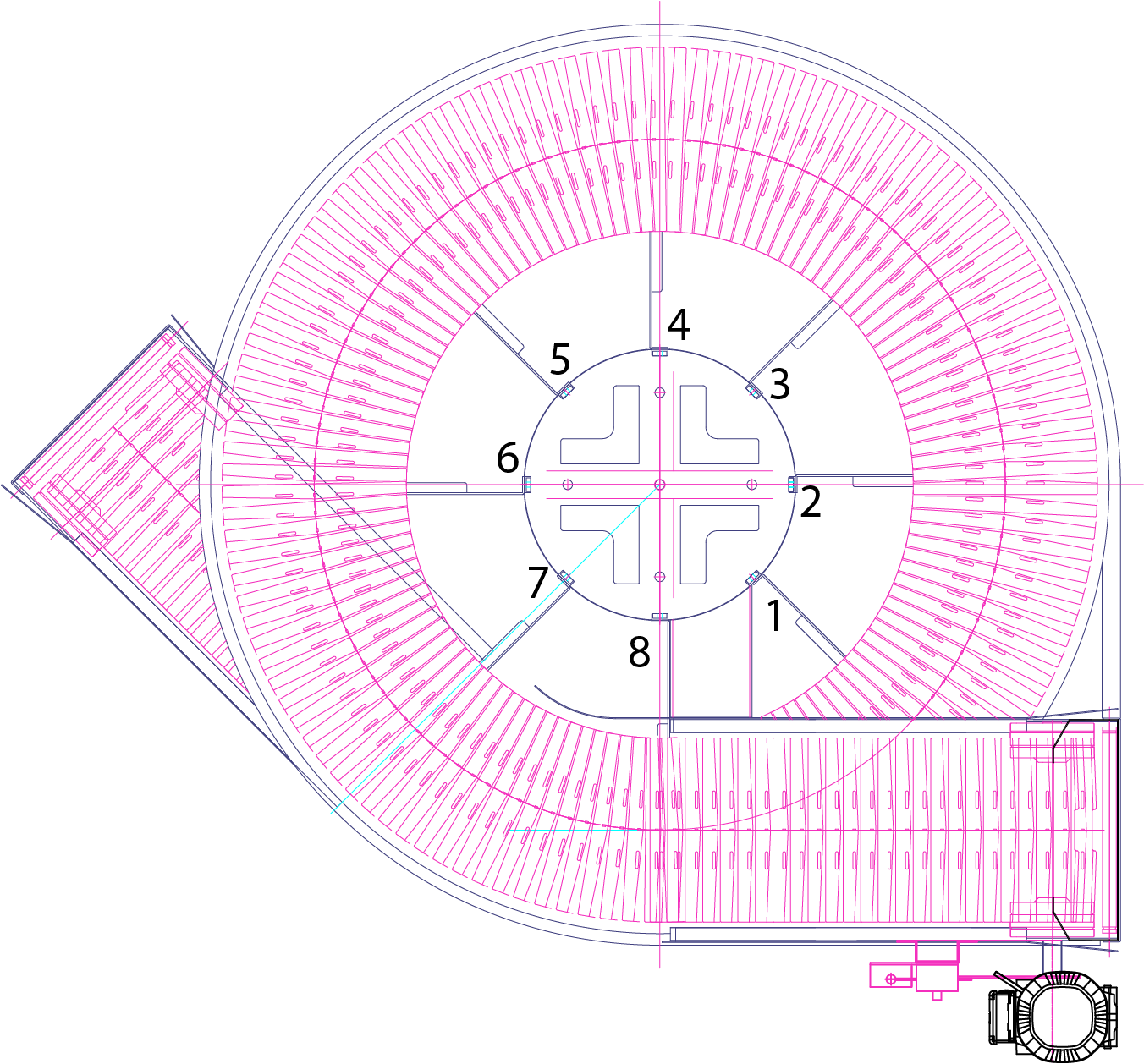

A recent project with Integrator Partner Sidel highlights how adaptable Ryson Spirals can be. This Spiral supports a high-speed bottling line at a brewery, where sanitation, speed, and layout efficiency remain critical. This application also showcases several customizable Vertical Conveying Options that often go unnoticed during early design discussions.

- This Spiral uses Ryson’s Hybrid Design. The center column and spiral track feature powder-coated aluminum, while the exterior guards, base frame, and hardware use stainless steel. Zinc-plated steel supports the remaining structure, including the load arms. Stainless steel bearings ensure suitability for wet environments. Together, these materials balance corrosion resistance with cost control, offering a practical alternative to fully stainless systems.

Custom tangents further enhance layout efficiency. By extending the infeed or discharge beyond the Spiral base, designers can remove unnecessary curved conveyors. In this brewery application, the configuration eliminates the need for a 90-degree curve at discharge. Fewer conveyors reduce energy consumption, simplify maintenance, and minimize transfer points that can disrupt flow.

Custom tangents further enhance layout efficiency. By extending the infeed or discharge beyond the Spiral base, designers can remove unnecessary curved conveyors. In this brewery application, the configuration eliminates the need for a 90-degree curve at discharge. Fewer conveyors reduce energy consumption, simplify maintenance, and minimize transfer points that can disrupt flow.- Speed control also plays a key role in system performance. Ryson specifies each Spiral to a defined operating speed, while variable frequency drives allow fine adjustments once production begins. This flexibility helps match upstream and downstream equipment. In this case, the Spiral operates at 200 feet per minute, supporting high-speed bottling while maintaining product stability.

Product stability depends on speed, incline, and container type. Ryson addresses these variables with optional friction enhancements. Slats can include friction nubs to reduce slide-back on challenging products. Available friction levels of 25, 50, or 100 percent allow precise tuning for each application.

Product stability depends on speed, incline, and container type. Ryson addresses these variables with optional friction enhancements. Slats can include friction nubs to reduce slide-back on challenging products. Available friction levels of 25, 50, or 100 percent allow precise tuning for each application.

Together, these Vertical Conveying Options help food and beverage producers maximize space, simplify layouts, and maintain reliable operation. Ryson Spirals adapt to real-world production demands without unnecessary complexity. For more details on configurable features, visit the Ryson Spiral Conveyors page.