The Smart Advantage of Reconfiguring a Ryson Spiral

Production floors keep evolving, and many facilities now pursue Production Floor Equipment Upgrades to stay competitive. As layouts shift and automation expands, existing conveying equipment often needs to adapt. Fortunately, a Ryson Spiral already offers a built-in advantage: its modular design supports efficient and cost-effective reconfiguration.

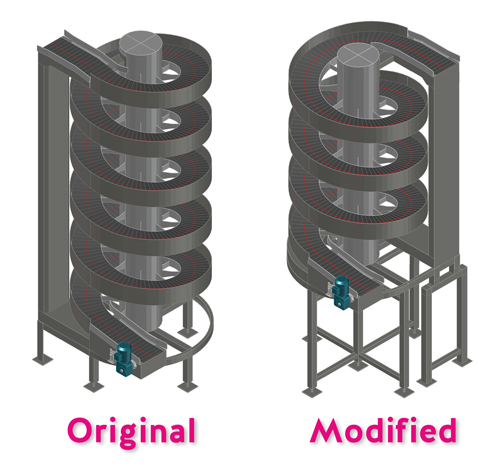

When facilities upgrade machinery, add new automation, or reduce their operational footprint, space becomes a priority. A Spiral that once fed a certain line may now need a new discharge height, direction change, or extended elevation. Instead of replacing the entire unit, a reconfiguration allows teams to repurpose their existing investment. This approach keeps projects smart, fast, and budget friendly.

The Ryson design makes this possible. Every Spiral consists of modular components that technicians can add, remove, or re-space without rebuilding the framework. Because of this, most reconfiguring jobs happen on-site with limited interruption to production. In many cases, crews can complete the work in a single visit. The cost benefit is clear. A reconfigured Spiral operates like new at a fraction of the price of buying one.

“We recently supported a customer who needed more accumulation between their Spiral discharge point and a floor-level case packer. Their existing 1500-400 Spiral Conveyor declined empty cases from an automatic case erector on a mezzanine, but the line update required extra conveyor length to accommodate the additional accumulation demand. Our team proposed a revised design that lifted the discharge to a higher elevation and added a conveyor loop after the Spiral to create the needed distance. The reconfiguration also included an extended leg base platform, allowing the new conveyor path to pass cleanly under the Spiral on its way to the packer.”

– Steve Dillaman, Key Account Manager

Reconfiguration also supports broader operational goals. As companies adopt new automation, they often rethink product flow. A Spiral that once sat deep in a line may gain new value when redeployed toward storage, palletizing, or packaging. By adjusting the unit rather than replacing it, facilities maintain uptime and reduce waste.

When companies try to free up floor space, the impact grows even more. Reconfiguring a Spiral can help consolidate equipment, open aisles, and increase storage or production capacity. This approach creates a more flexible layout while keeping capital spending under control.

Every reconfiguration also receives the attention of the Ryson service team. They assess the unit’s condition, plan the mechanical changes, and confirm that the Spiral meets the revised application needs. The result is dependable performance that aligns with your updated operation.

As production environments change, a Ryson Spiral remains adaptable. Its modular structure turns Production Floor Equipment Upgrades into a practical opportunity rather than a major expense. Reconfiguring maximizes your original investment and lets your facility grow with confidence.