![]()

Spiral conveyors have become indispensable in various industries, offering efficient vertical transport solutions that maximize space and throughput. Their versatility allows them to adapt to different operational needs, temperature ranges, and product handling requirements.

In this article, we explore how spiral conveyor applications are ideal for Ryson Machinery – across some key sectors: Grocery & Food Distribution, Beverage Bottling & Packaging, Cold Chain Logistics, and Pharmaceutical & GMP Facilities.

1. Grocery & Food Distribution

1. Grocery & Food Distribution

Spiral conveyors are used for vertical transport of cases, totes, or trays between picking and shipping areas in grocery and food distribution centers. (Ambient: chilled environments, Examples: food delivery services, cooking box subscriptions etc.)

-

Maximizes throughput even in tight backroom spaces

-

Supports high SKU turnover, enabling efficient handling of diverse product assortments

- Ideally suited for multi-level pick module operations and minimizes floor space in expensive cooler environments.

This application is ideal for grocery operations where space is limited but speed and flexibility are critical to meet consumer demand and maintain inventory flow.

2. Beverage Bottling & Packaging

2. Beverage Bottling & Packaging

- Mass-flow spiral conveyors transport bottles and cans between filling, packaging. Up to 2,000 bottles or cans per hour.

-

They handle high volumes with a minimal footprint, optimizing floor space

-

Supports line flexibility and vertical accumulation, allowing smooth integration into complex packaging systems

This use case is essential for beverage manufacturers aiming to maintain high throughput while ensuring product safety and line adaptability.

3. Warehousing / Logistics / eCom

3. Warehousing / Logistics / eCom

Spiral Conveyors also have become and indispensable part of warehouses and modern DCs. They move boxes, totes, and parcels between multi-level mezzanines, storage, and shipping docks. Their space-saving design helps maximize storage density and streamlines order fulfillment in high-volume distribution centers and automated warehouses. They are also perfect for vertical expansion projects.

- Can introduce or divert product from multiple levels

- Simple integration with existing structures and conveyors

- Can handle large and heavy loads

4. Cold Chain

Spiral conveyors move frozen or refrigerated goods between storage areas and loading docks in cold chain logistics operations. Accommodating subzero environments down to -40°F

-

Maintains product integrity by operating efficiently in cold conditions

-

Energy-efficient design reduces operational costs in temperature-controlled settings

- “One size fits all” conveying, offering a smooth and consistent conveying surface for varied sizes and shapes.

Cold chain logistics benefit greatly from spiral conveyors that preserve product quality while ensuring timely and efficient movement of goods.

5. Pharmaceutical Manufacturing

Used for conveying packaged medicines, vials, or components between levels in pharmaceutical manufacturing facilities.

-

Low power consumption, minimal maintenance and gentle product handling

- Our smallest Spirals, the Narrow Track can handle smaller packages reliably, like blister packs and vials, etc.

-

Integrates seamlessly with automated storage and retrieval systems

In pharmaceutical settings, spiral conveyors offer high-speed conveying while ensuring safe, gentle and efficient product handling in a small footprint.

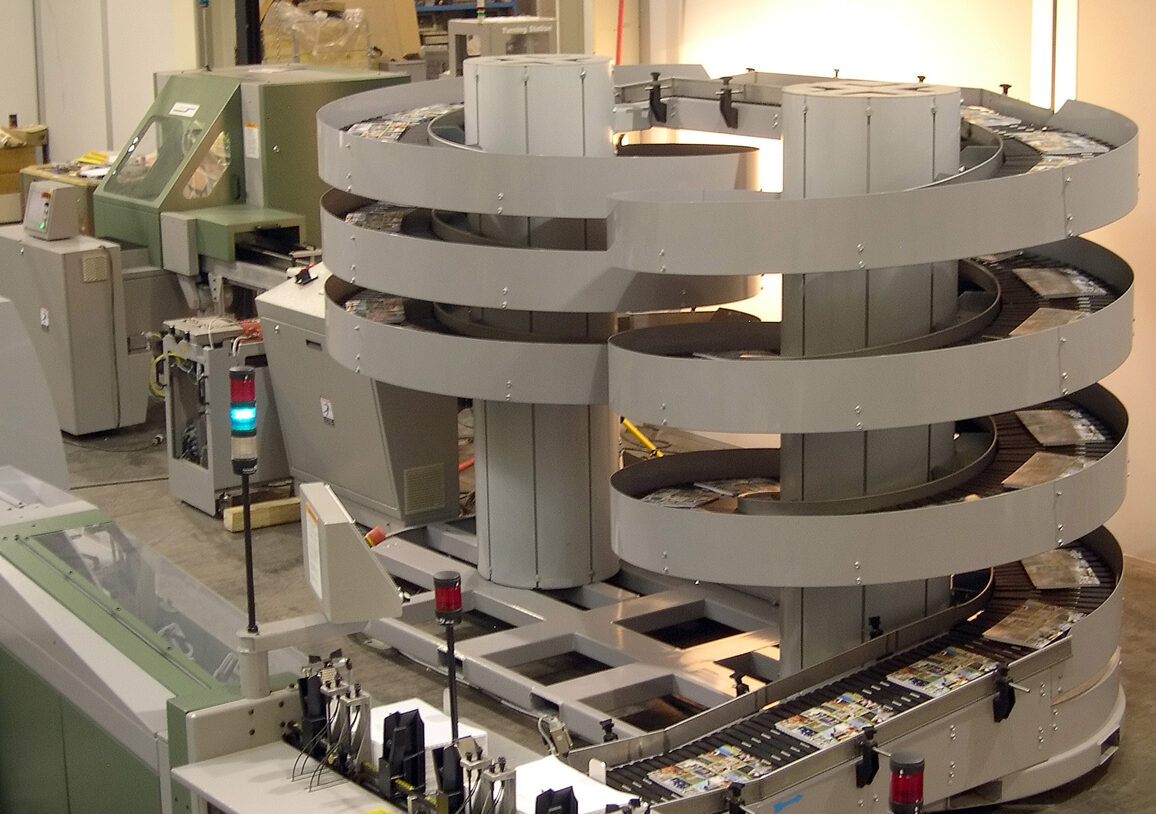

6. Printing & Publishing

6. Printing & Publishing

Ryson Spirals are being used in conveying newspapers, magazines, or printed materials from presses to binding, stitching, or packaging lines. Using spirals maintains product orientation and continuity, supporting high-speed end-of-line operations.

- Can run at slow speeds for drying or curing

- Can provide vertical accumulation

| Sector | KPI (cases/h) | °F Range | Key Benefit |

|---|---|---|---|

| Grocery | 1,500 | Ambient–40°F | High throughput, tight spaces |

| Beverage | 2,000 | 35–100°F | Volume, flexibility, accumulation |

| Cold Chain | 800–1,200 | -20–40°F | Product integrity, energy savings |

| Pharma | 400–800 | 60–75°F | Gentle, small products, reliable |

Spiral conveyors demonstrate remarkable adaptability across industries, from the fast-paced grocery sector to the highly regulated pharmaceutical field. Their ability to operate under diverse temperature conditions and handle varying product volumes makes them a vital component in modern material handling systems, driving efficiency and reliability in supply chains worldwide. You can find more application examples on our own YouTube Channel.